-

Design Capabilities

KINGREAL STEEL SLITTER is equipped with a professional design team, which consists of professional engineers who have been engaged in the research and development, manufacturing and installation of metallurgical equipment for a long time. The members generally have more than 10 years of industry experience. The design team members have interdisciplinary knowledge, digital tool application capabilities and continuous innovation awareness, and are committed to helping improve the steel coil slitting line and cut to length line to accurately control material properties, process parameters and customer needs.

-

Manufacturing Capabilities

KINGREAL STEEL SLITTER has a factory area of 15,000 square meters, including 5,000㎡ of assembly workshop, 2,000㎡ of CNC processing workshop, 5,000㎡ of finished product workshop, 1,000㎡ of riveting and welding workshop, and 2,000㎡ of warehouse.

KINGREAL STEEL SLITTER is equipped with precision processing equipment, using large gantry milling machines and CNC machine tools to process core components such as the cutter shaft and roller of coil slitting machine and cut to length line, which can ensure that the radial runout of the cutter shaft is ≤0.05mm and the cutting accuracy is stable within ±0.02mm. -

Quality Control System

KINGREAL STEEL SLITTER has a strict quality control system to ensure that the precision of each component of the coil slitting line and cut to length line meets the customer's production requirements.

KINGREAL STEEL SLITTER can provide customers with a complete production inspection record sheet and after the completion of production, KINGREAL STEEL SLITTER will carry out idle production line in the factory for the inspection process, to ensure that the production line is running smoothly. -

After-Sales Service

KINGREAL STEEL SLITTER after-sales service has been widely recognized by customers from all over the world.

KINGREAL STEEL SLITTER establishes a separate after-sales service team for customers, which can answer customers' technical and operational questions online all day long, and at the same time, according to the actual needs of customers, KINGREAL STEEL SLITTER engineers are able to go to customers' factories to carry out on-site installations and operation teaching and other after-sales services. -

Accessory Backup

KINGREAL STEEL SLITTER establishes a distributed spare parts library covering common wearing parts such as blades, bearings, hydraulic nuts, etc. At the same time, it has its own machining workshop to produce core parts and establishes a spare parts library to shorten the maintenance cycle.

All spare parts are tested quarterly according to ISO standards and quality traceability service is provided. In addition, we support the customization of non-standard parts and technical upgrading synchronous guidance to reduce the risk of customer downtime. -

Technology Upgrade

KINGREAL STEEL SLITER, as a supplier of coil processing equipment, has been continuously upgrading the technical design and manufacturing process of the coil slitting line and cut to length line to help our customers obtain the best production solutions and create long-term production benefits.

KINGREAL STEEL SLITTER is able to offer its customers a wide choice of production solutions in different designs.

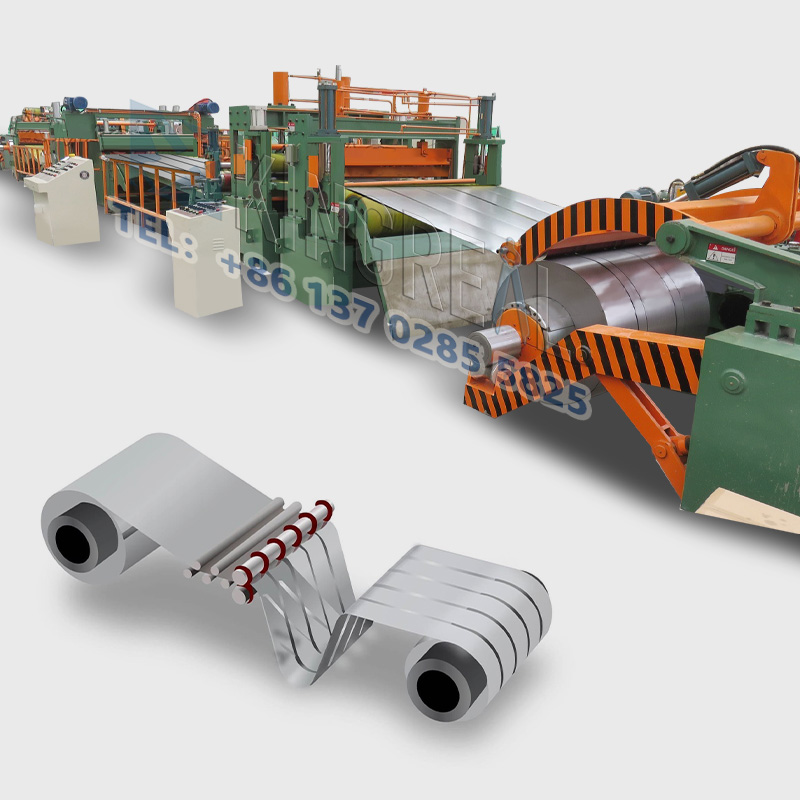

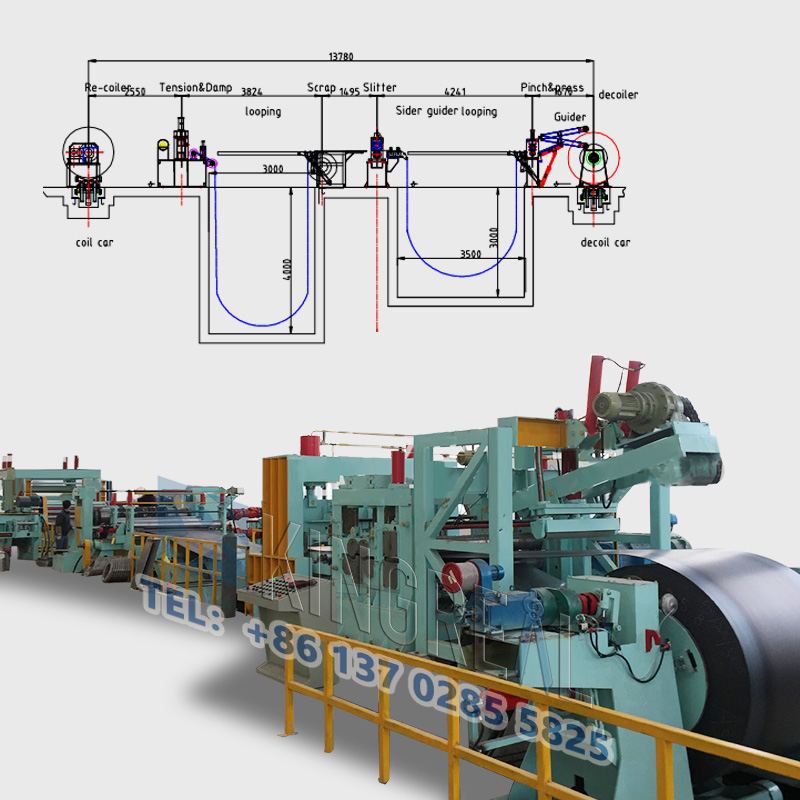

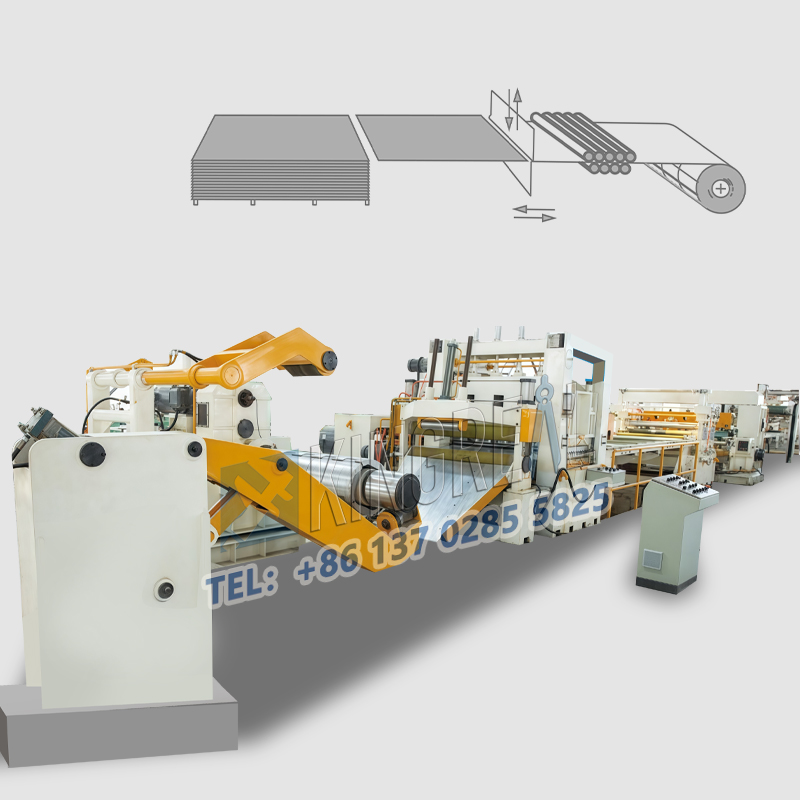

- Coil Slitting Machine

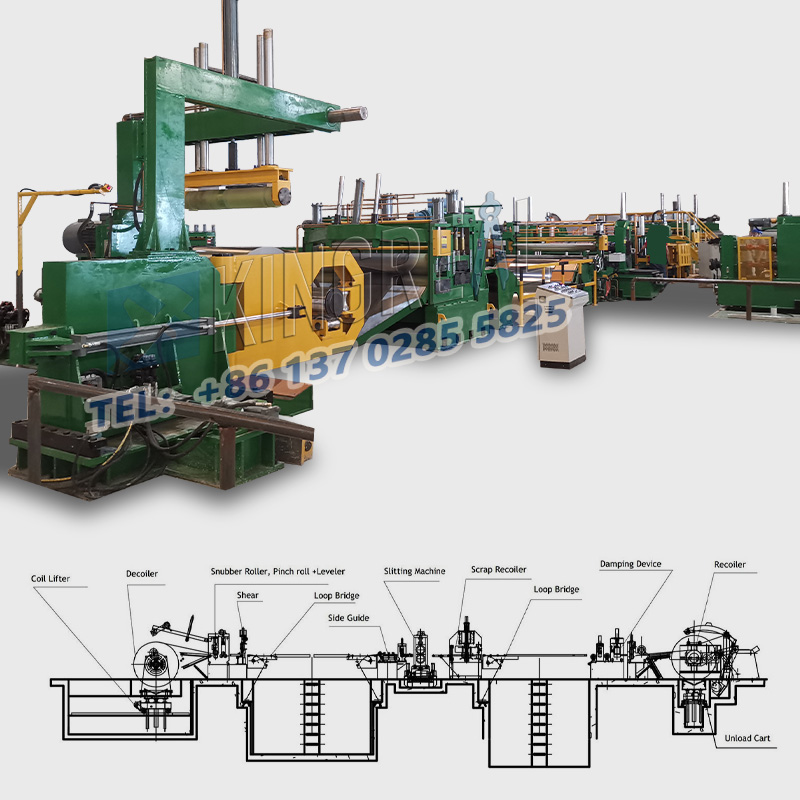

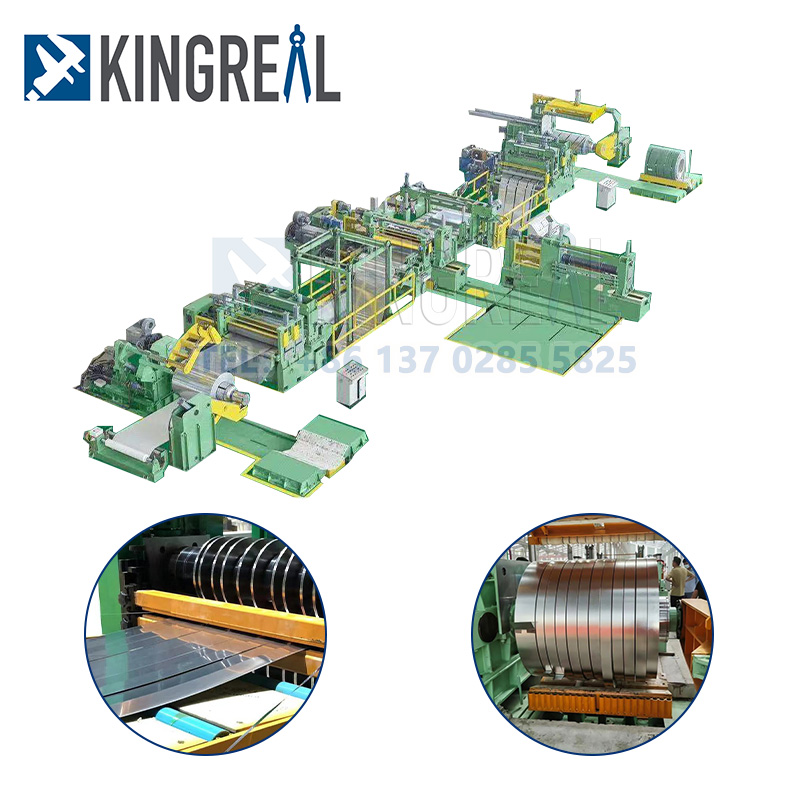

The coil slitting line is the core production line of coil processing equipment, capable of realizing the process of continuously shearing wide metal coils along the longitudinal direction into multiple narrow strips and rewinding them into individual coils.The core production components of the Steel coil slitting line include decoiler, straighteners, longitudinal shears, waste edge collection devices, tension control fonts and The core production components include uncoiler, straightener, longitudinal shear, waste edge collection device, tension control font, and rewinding machine, etc. It is suitable for the slitting process of carbon steel, stainless steel, silicon steel, galvanized sheet, tinplate and other materials.

Metal coil slitting machine can help metal processing and manufacturing industry, construction and infrastructure industry, automotive industry, and home appliance packaging and other industries to provide metal raw materials precision slitting winding process to produce a specified width of the narrow strip coil, can be directly into the secondary processing production.

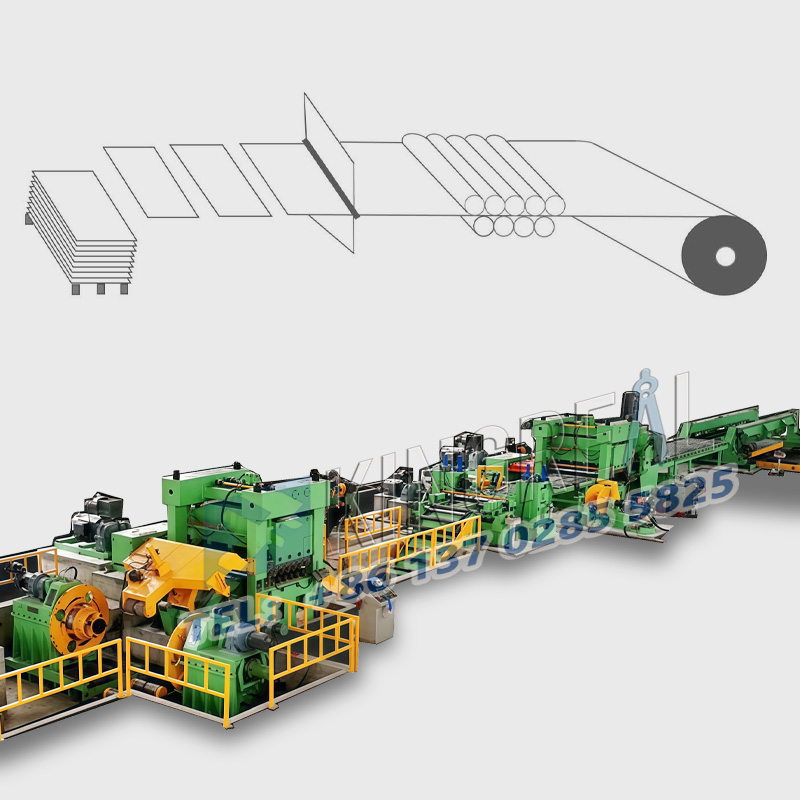

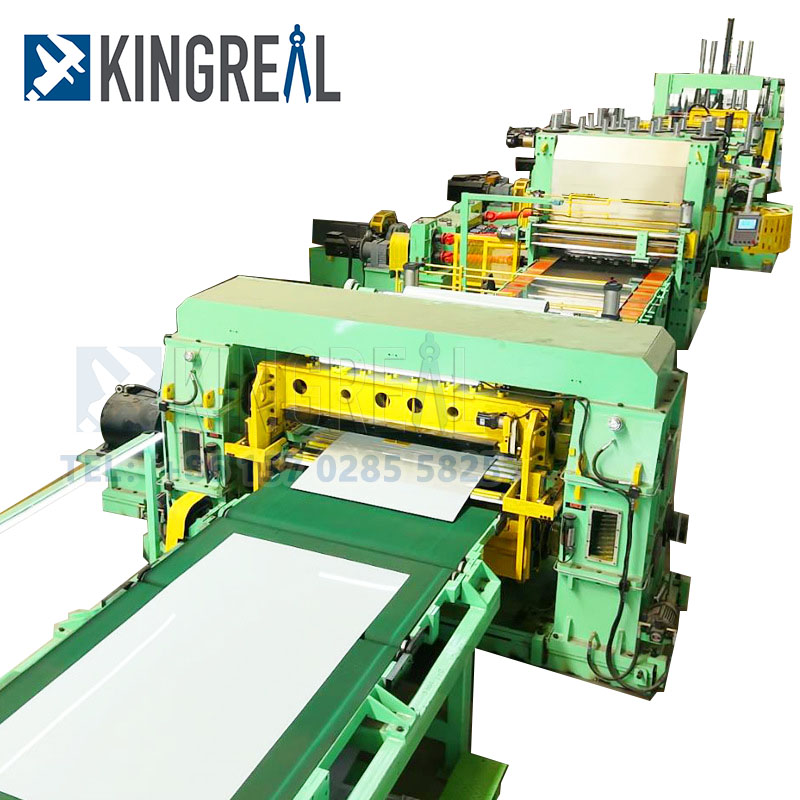

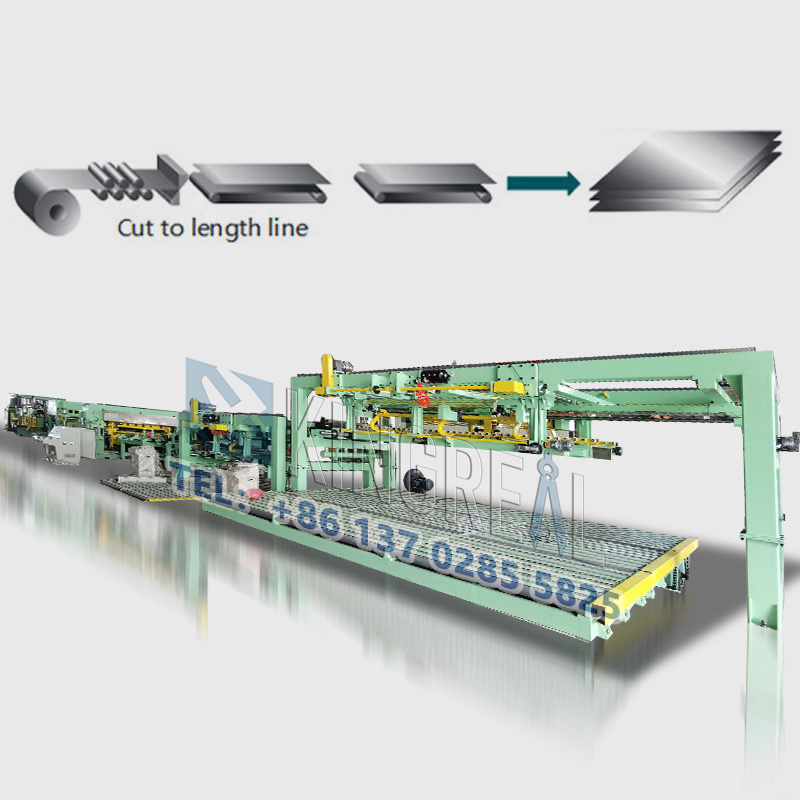

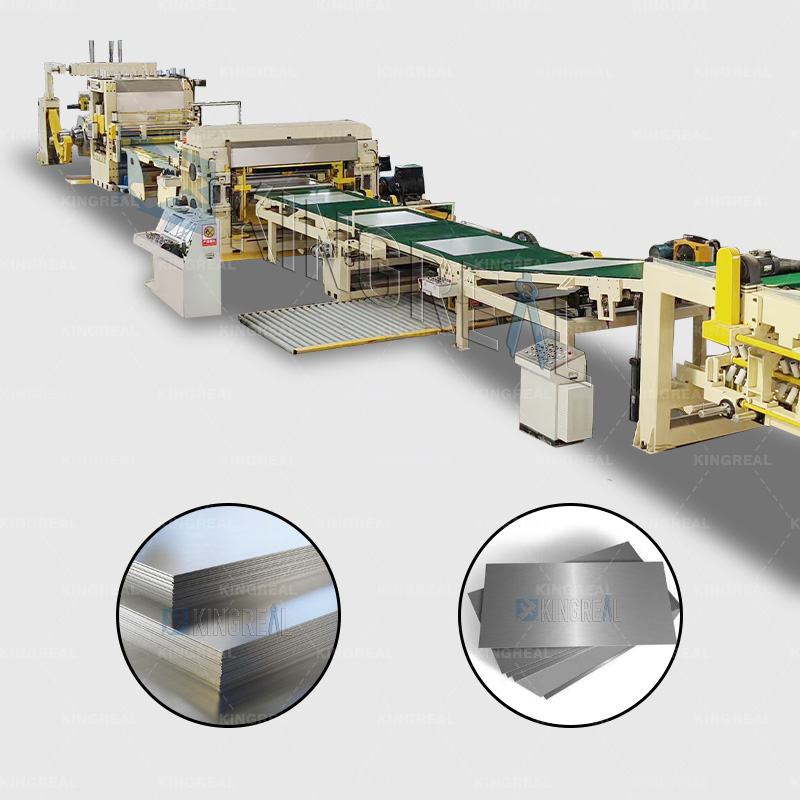

- Cut To Length Line

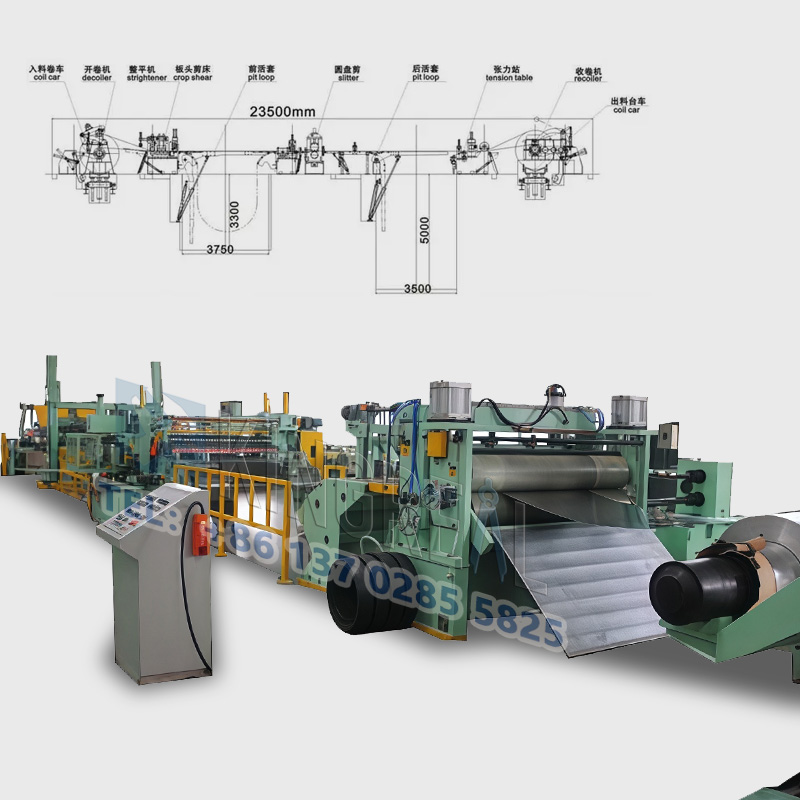

Cut to length lines also called levelling cut to length blanking line is the most important metal processing machinery core equipment, mainly used for metal coil of various materials along the transverse cut into a specific length of metal sheet final stacking industrial equipment. The main production process of cut to length machine includes uncoiling, levelling, cut to length blanking and stacking, according to the customer's actual coil processing needs with different devices to realize the precision of cut to length production process.

Cut to length line is capable of producing slit silicon steel coils for core lamination to meet the electromagnetic performance requirements of transformers and motors, cold rolled/hot rolled carbon steel cut to length sheets for structural steel beams, roofing panels, etc., as well as slit tinplate, coated steel sheets for food cans, packaging boxes, etc. The Cut to length machine is capable of cutting cold rolled steel, hot rolled steel, stainless steel, tinplate, silicon steel and stainless steel coils in different sizes, Stainless steel, tinplate, silicon steel roll coated steel plate and other raw materials can be cut into metal sheets of specified width.

- Coil Perforation Line

Coil perforation line, sheet metal perforated making machine is used to continuously process uniform perforations in metal coils to meet specific application requirements.Metal perforated making machine adopts servo control system or mold positioning technology to ensure the The machine uses servo control system or die positioning technology to ensure the consistency of perforation spacing and diameter, and is capable of processing a wide range of raw materials such as aluminum, stainless steel, and galvanized steel coils, with thicknesses ranging from 0.1-6MM, and supporting custom-designed metal perforation production solutions.

KINGREAL STEEL SLITTER core metal perforated making machine punching technology is the use of gantry punching machine punching, in order to meet the diverse punching needs of customers, and gradually introduce laser engraving or CNC stamping technology, support for complex patterns of customized perforation, and at the same time to reduce the time of tooling replacement!

-

High Precision Coil Slitting Machine

USA

-

Coil Perforation Line

Italy

-

Min Coil Slitting Machine

Brazil

-

High Speed Cut To Length Line

Poland

KINGREAL STEEL SLITTER is KINGREAL MACHINERY factory specializing in the production and manufacturing of coil processing equipment.

- Coil Slitting Machine ,Cut To Length Line and Metal Perforated Machine essentially function to process metal coils and have a wide range of applications in all major industries. KINGREAL STEEL SLITTER is a specialized manufacturer of coil processing equipment and is committed to bringing high quality machines and equipment to our customers.

- For more than 20 years, KINGREAL STEEL SLITTER has been focusing on optimizing and innovating different processes to ensure that its machine products bring project success to its customers in terms of production quality, productivity and longevity.

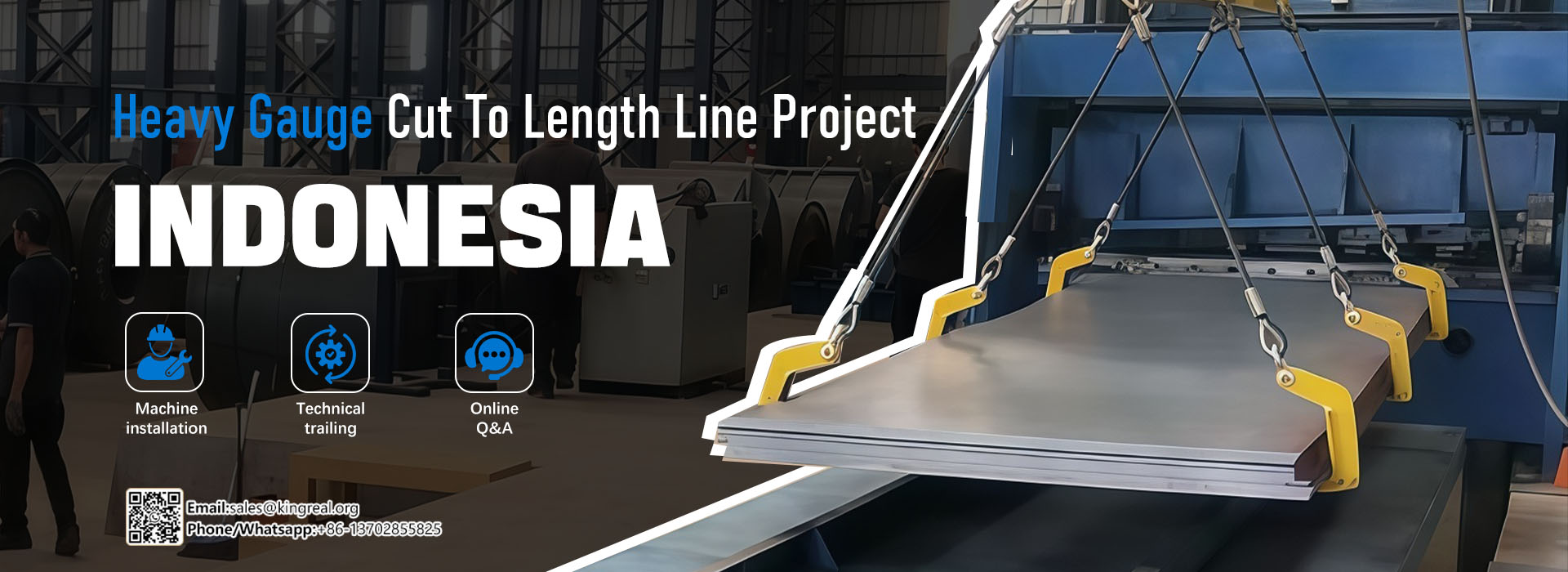

- “Professional technical level and perfect after-sales service”is the principle that KINGREAL STEEL SLITTER has been adhering to for many years, to be responsible for every customer, to do a good job of installation and after-sales service for every project, in order to make us get the recognition of customers from all over the world. So far, KINGREAL STEEL SLITTER has reached a long-term and stable cooperation with Indonesia, Saudi Arabia, the United Arab Emirates, Turkey and Russia and other countries and regions.

- New innovations and developments continue in 2025, welcome to KINGREAL STEEL SLITTER.