KINGREAL STEEL SLITTER heavy gauge cut to length machine is designed specifically for processing thick plate materials and can handle a variety of metal materials, increasing production output.

Video About Heavy Gauge Cut To Length Machine

Video About Heavy Gauge Cut To Length Machine

Brief introduction of Heavy Gauge Cut to Length Machine

Brief introduction of Heavy Gauge Cut to Length Machine

KINGREAL STEEL SLITTER heavy gauge cut to length machine is designed for customers with special customization needs and is designed for large coils with a thickness range of 6-25 mm.

This heavy gauge cut to length line has the characteristics of adjustable speed, easy operation, high degree of automation, and the heavy gauge cut to length machine also supports the display of information such as length, number of shears and speed. It is widely used in metal manufacturing, construction projects, aerospace, military and other fields.

Since the heavy gauge cut to length line shears thick materials, KINGREAL STEEL SLITTER has correspondingly upgraded the heavy gauge cut to length machine performance and parameters, equipped the heavy gauge cut to length line with a more robust stripping and material handling section, and also equipped it with a harder blade.

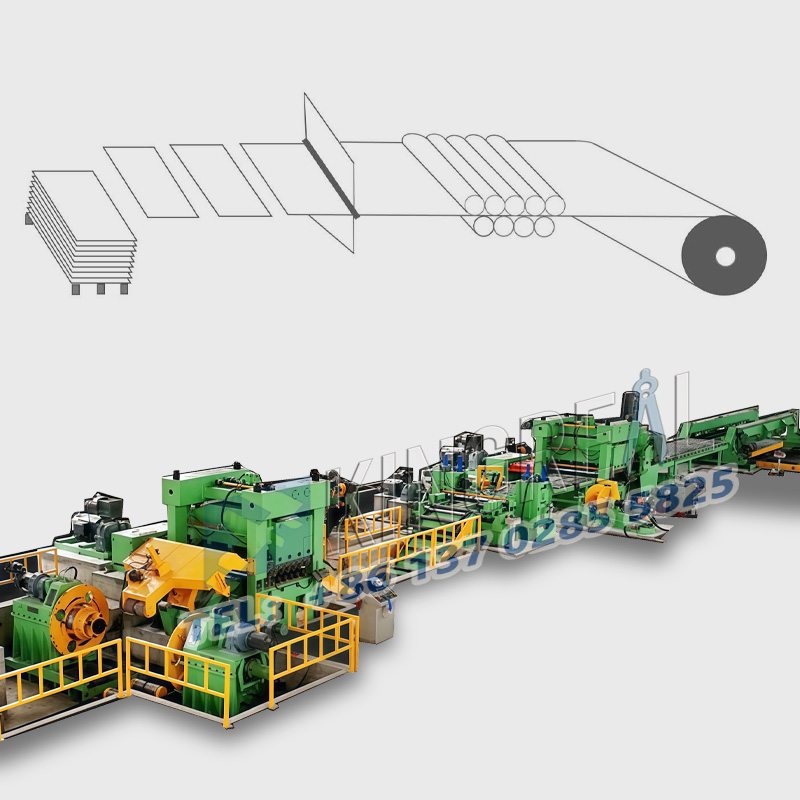

The heavy gauge cut to length machine is mainly consist of hydraulic coil car, hydraulic decoiler, straightener, measuring, cutting machine, auto stacker and electrical system, etc,.

This heavy gauge cut to length line is suitable for different materials with high specifications, such as hot-rolled steel, cold-rolled steel, stainless steel, copper strip and silicon steel, etc. According to the different needs of customers, KINGREAL STEEL SLITTER has a professional design and production team for customized production. Welcome to contact us

KINGREAL STEEL SLITTER Heavy Gauge Cut To Length Machine Working Process

KINGREAL STEEL SLITTER Heavy Gauge Cut To Length Machine Working Process

Trolley for coil loading -- Hydraulic Decoiler -- Guiding&Pressing Unit -- 2 Pinch Rolls Leveling Machine -- Sheet Transmission Table -- Heavy Gauge Shearing Machine -- Auto Stacker

Main Components Detail Of Heavy Gauge Cut to Length Line

Main Components Detail Of Heavy Gauge Cut to Length Line

KINGREAL STEEL SLITTER provides corresponding decoiler and feeding trolley according to the working width and outer diameter of the coil required by the customer.

Among them, decoiler and feeding trolley with a maximum weight of 30 tons can be provided for heavy gauge cut to length machine . Equipped with a feeding trolley, the heavy gauge cut to length line can reduce manual handling and realize automated production.

In order to more accurately level the material with larger specifications, KINGREAL STEEL SLITTER straightener machine can have different designs from 2H-6H, which can be flexibly controlled for accuratedly leveling of the sheet.

KINGREAL STEEL SLITTER heavy gauge cut to length line use one or two pairs of feeding roller, driven by AC servo motors, to feed the sheet to the cutting length precisely.

They can be equipped with roller or belt conveyors.

KINGREAL STEEL SLITTER can provide different shearing methods for heavy gauge cut to length lines, including rotary shearing, swing shearing and fly shearing. KINGREAL STEEL SLITTER will make suggestions based on the customer's production needs (output, metal thickness, metal material, use, etc.) and provide different shearing method solutions for heavy gauge cut to length machines.

Stacker for Heavy Gauge Cut to Length Line

KINGREAL STEEL SLITTER equips the heavy gauge cut to length machine with a stacking table, which automatically stacks the metal sheets to reduce manual handling.

In addition, to maximize production efficiency, KINGREAL STEEL SLITTER can also equip the heavy gauge cut to length line with double stacking table.

Advantages Of Heavy Gauge Cut To Length Machine

Advantages Of Heavy Gauge Cut To Length Machine

KINGREAL STEEL SLITTER heavy gauge cut to length line is controlled by PLC system to realize fully automatic production.

Before the heavy gauge cut to length machine runs, it is only necessary to input the required product length, cutting quantity and machine cutting speed information into the PLC system.

After the input is completed, the machine starts to operate. When the required cutting length is reached, the machine will automatically cut.

According to the production speed required by customers, KINGREAL STEEL SLITTER heavy gauge cut to length line can achieve high measurement accuracy and automatic operation of the whole line.

- Intelligent operating system, easy to operate, can produce smooth boards.

Specification Of Heavy Gauge Cut To Length Machine

Specification Of Heavy Gauge Cut To Length Machine

|

Machine Type |

Heavy Gauge Cut To Length Machine |

|

Material |

Stainless steel, copper strip, silicon steel, cold rolled and hot rolled steel, etc. |

|

Max Coil Thickness |

25mm |

|

Max Coil Weight |

3600mm |

|

Max Coil Height |

30 Ton |

|

Max Cutting Length |

24m |

|

Cutting Speed |

60m/min |

|

Cut Tolerance |

±0.01mm |

Application of Heavy Gauge Cut to Length Machine

Application of Heavy Gauge Cut to Length Machine

- Integrated factory

- Eetal material processing plant

- Aerospace/Military Industry

- Manufacturing

- Construction industry

KINGREAL STEEL SLITTER Services

KINGREAL STEEL SLITTER Services

1.OEM

2.Spare parts

3.One year warranty

4.24 hours technical support

5.Fast delivery

FAQ

FAQ

Yes, KINGREAL STEEL SLITTER are the cut to length line manufacturer. KINGREAL STEEL SLITTER have a factory and our own technical team, feel free to visit us.

Our factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct toFoshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

We will pick you up at the station or airport.

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?

Contact us immediately. KINGREAL STEEL SLITTER offer free pre-sales service advisors, and we can also help you with raw material (steel coils) procurement, worker training, international market prices, etc.