Steel Cut to Length Machines are used to cut large metal coils into manageable lengths. Steel Cut to Length Machines are ideal for hard or thick metal materials such as steel, stainless steel and aluminum, and feature high working speeds and high measurement accuracy.

Video About Steel Cut To Length Machine

Video About Steel Cut To Length Machine

KINGREAL STEEL SLITTER Steel Cut To Length Line Project

KINGREAL STEEL SLITTER Steel Cut To Length Line Project

Brief Introduction of Steel Cut To Length Machine

Brief Introduction of Steel Cut To Length Machine

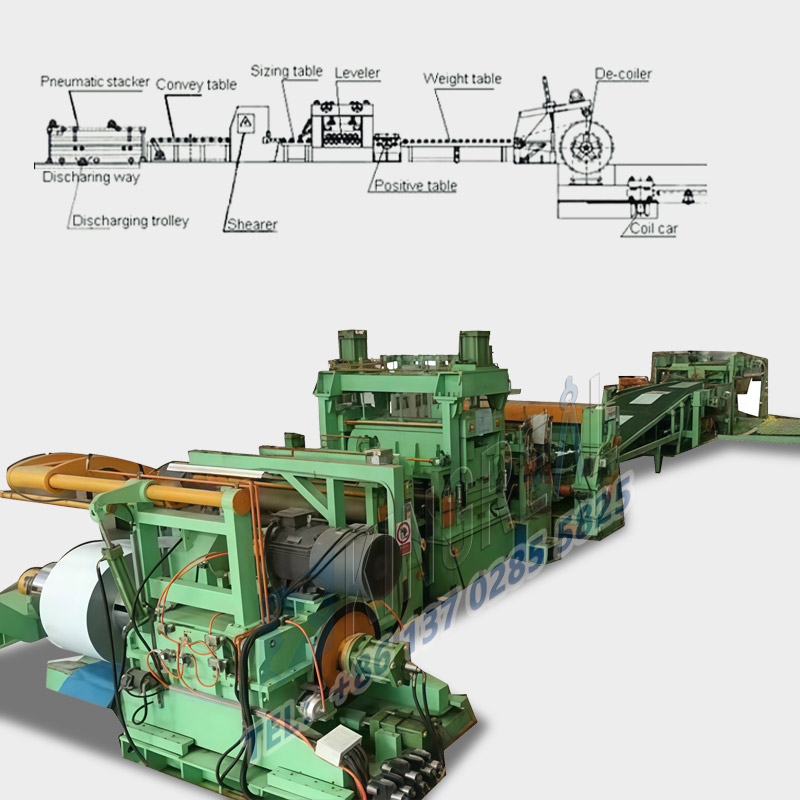

KINGREAL STEEL SLITTER steel cut to length machine is usually used for accurately cutting required length steel sheet from roll coil throught a series of prodcution processes. In addition to steel cut to length machine, KINGREAL STEEL SLITTER metal cut to length line is suitable for various production materials such as stainless steel, metal, cold rolled steel and hot rolled steel, etc.

The equipment configured in the steel cut to length line is not fixed, KINGREAL STEEL SLITTER can produce customized production machines according to your needs. For pecific needs, KINGREAL STEEL SLITTER design the touch screen, which can set on the length and cutting quantity of coil . The automatic steel cut to length line adopts the servo motor to measure the length, which can ensure product accuracy.

KINGREAL STEEL SLITTER has been focusing on the field of steel cut to length line for more than 20 years, and has successfully produced and transported the stainless steel cut to length line, metal cut to length machine,heavy gauge cut to length line, etc,.to all around the world.

Working Process Of Steel Cut To Length Machine

Working Process Of Steel Cut To Length Machine

Trolley for heavy coil→ Hydraulic decoiler → Traction head→Pinch feed roller feeding → Leveling device → Fixed length cutting → Unloading table

Mainly components of Steel Cut To Length Line

Mainly components of Steel Cut To Length Line

Six-fold precision leveling machine, straightening machine or leveling machine is an important part in the cut to length line. It will affect the flatness of the final plate. High precision, good stability, its leveling rollers are made of roll steel with chrome plated surface. Good wear resistance and long service life.

Adopt advanced flying shear head, high-speed double crank rotation continuous shear on the board tracking, using advanced German servo control system, rotary (upper and lower knife to shear) up and down drive blade precision on the board shear.

Stacking and baling of processed sheets, while avoiding collisions and friction between sheets.

Matters Needing Attention During Steel Cut To Length Machine Operation

Matters Needing Attention During Steel Cut To Length Machine Operation

√ After the material is loaded, the center positioning should be measured and the hole distance should be checked to see if it is correct.

√ Must stop and change speed. When the machine is running, it is strictly forbidden to touch the material with your hands, not to touch the mold and motor with your hands.

√ The machine guide, the mold is strictly prohibited to put work, measuring tools and gloves and other items.

√ Do not leave the machine after the machine is turned on, to concentrate on the operation.

√ At the end of the day, wipe the machine, organize the site, cut off the machine power. Lubricate the machine gears.

√ During processing, if you find that the machine does not sound normal or malfunction, you should immediately cut off the power, diagnose the problem or notify the manufacturer.

Technical Specification of Steel Cut To Length Machine

Technical Specification of Steel Cut To Length Machine

|

Machine Type |

Steel cut to length machine |

|

Coil Material |

Steel sheet(other can be supply |

|

Max Coil Thickness |

3mm |

|

Max Coil Weight |

1600mm |

|

Max Coil Height |

20 Ton |

|

Coil I.D |

508mm,610mm,760mm |

|

Coil O.D |

≤2000mm |

|

Max Cutting Length |

24m |

|

Cutting Speed |

60m/min |

|

Cut Tolerance |

±0.01mm |

|

Electrical Control System |

PLC automatic control |

FAQ

FAQ

KINGREAL STEEL SLITTER is a professional manufacturer and supplier.

KINGREAL STEEL SLITTER offers full solutions in coil processing and machine tool building, which including high speed coil slitting line, copper slitting machine, 200m/min coil slitting machine, simple slitting machine, metal cut to length line, fly shearing cut to length machine, fixed shearing cut to length machine.

KINGREAL STEEL SLITTER has a professional team and rich project experience, can provide you with the best service, welcome to contact us.

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct toFoshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

KINGREAL STEEL SLITTER will pick you up at the station or airport.

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?

KINGREAL STEEL SLITTER factory is located in Foshan, Guangdong, China. Visitors are welcome to tour the factory and see the steel cut to length machines. Contact KINGREAL STEEL SLITTER today to get the latest price list and quotation.