KINGREAL STEEL SLITTER Sheet Metal Cut to Length Machine is usually used to decoiler, leveler and cut coils of different materials and thicknesses to the widths specified by customers. Common coil thicknesses range from 0.3-3mm, with different production designs for different raw materials and production requirements. Please feel free to send your request to KINGREAL STEEL SLITTER!

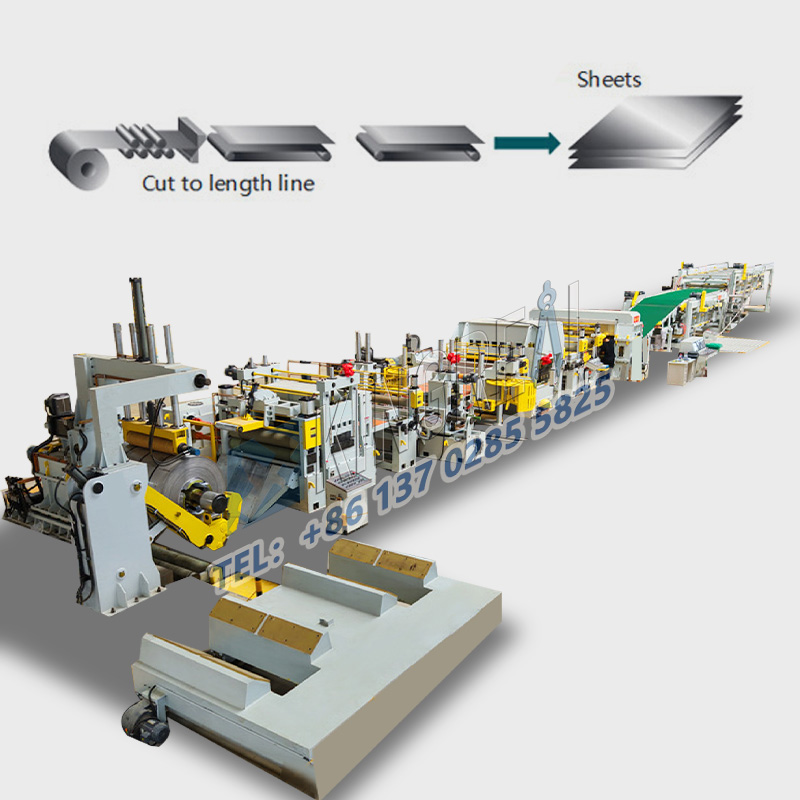

KINGREAL STEEL SLITTER is engaged in the field of coil processing equipment manufacturing, providing customers with a range of services in design, production and sales. The most distinctive products are Coil Slitting Machine And Cut To Length Line. These machines are widely used for slitting, shearing or punching metal sheets into different sizes and shapes. Sheet metal cut to length line is one of KINGREAL STEEL SLITTER features coil processing equipment, used to processing the coil to specified width sheet.

KINGREAL STEEL SLITTER sheet metal cut to length machine is used for uncoiling, leveling, feeding, cut-to-length, trimming and stacking of metal coils, applicable materials include aluminum coil, stainless steel, cold rolled steel, hot rolled steel, PPGI, copper strip, and other materials, which ensures that the diagonal accuracy of the sheet metal cut to length machine is ≤0.50 mm, and the maximum speed can be as high as 80M/Min.

Different thicknesses of coils, materials and shear widths will directly affect the design of the metal sheet cut to length line. The common thickness of coils is 0.3-3MM, and the common shear length is 1200-1600MM, which is one of the production requirements of most customers. At the same time, KINGREAL STEEL SLITTER can also customize the design according to the customer's specified production needs, either choose the heavy gauge cut to length line or the compact coil cut to length line.

With more than 20 years of experience in manufacturing and sales, KINGREAL STEEL SLITTER has been successfully selling its cut to length line to countries such as Saudi Arabia, India and Russia, and is able to provide optimal solutions and after-sales service.

(You can click here to download)

Coil trolley → Decoiler → Pinch feed roller feeding → High precision leveling device → Fixed length cutting → Unloading table / Automatic stacking table

|

Material of coils |

Chrome Steel, Galvanized Iron Sheet, Galvanized Aluminum Sheet

|

|

CoilThickness |

0.12-20mm

|

|

CoilWidth |

≤1300mm

|

|

Coil ID |

Φ508mm

|

|

Coil OD |

Φ1600mm

|

|

MaxCoilWeight |

10,000kg |

|

Feeding precision |

Length 1000±0.3mm, Diagonal 1000±0.5mm |

|

Cut to length line speed |

0-80m/min adjustable |

|

Pneumatic specification |

5 kg/cm² |

|

Stacker Sizes |

Min width 500mm, Max width 1300mm ;Min length 1200mm, max |

|

Other Size |

Length:5000mm;Height: 20-400mm

|

|

Feeding and shearing speed |

1m≤30m/min or depends on products length

|

|

Machine direction |

from left to right (To be confirmed) |

|

Total installation power |

About 35KW

|

- Coil Trolley Car

- Hydraulic Decoiler

- Entrance Guide

- Four / six high leveling machine

- Ring bridge

- Side guide pulley

- CNC servo feeding straightening machine

- Measuring system

- Shearing machine

- Conveyor table

- Pneumatic unloading device

- Hydraulic lifting table

- Unstacking car

- Hydraulic system

- Pneumatic system

- Electrical system PLC control

Function: It is used for leveling material and feeding in fixed length.

Main structure: leveling roller, electric part, back pressure roller assembly, feeding and discharging support seat assembly.

Leveling roller: Gcr15 Heat Treatment steel is quenched and tempered and then processed with high frequency treatment. After two times of electroplating and cylindrical grinding, the surface is glossy and has no traces, and the hardness reaches HRC62 degrees or more. The diameter of the leveling shaft is ø100mm. Manually adjust the worm gear to lift the leveling roller.

Function: It is used for cutting of fixed-length materials.

Main structure: main frame, blade, pneumatic clutch, electric part, etc.

Main frame: The whole frame is welded with high-quality carbon structural steel and has been annealed after welding.

Blade: The blade is made of Cr12 material, the heat treatment hardness reaches HRC62 degrees, and the four-sided cutting edge can be replaced.

Pneumatic clutch structure: changing the traditional mechanical braking method, low noise, long service life, and accurate.

Function: Used for material transportation.

Main structure: frame, hydraulic system, discharge rolling platform, etc.

Frame: It is welded with carbon steel, which is stable and firm. Scissor-type design, the cylinder is stretched and lifted.

Uplifting platform for discharging: The oil motor drives the transmission sprocket to drive the drum to rotate to transmit the material discharge.

Speed of sheet metal cut to length machine: Based on customer requirements, KINGREAL STEEL SLITTER offers sheet metal cut to length line manufacturing solutions to match the various speed levels of sheet metal cut to length machine. For example, KINGREAL STEEL SLITTER offers various coil cutting machine designs, stacking, and shearing systems. KINGREAL STEEL SLITTER common sheet metal cut to length line production speeds are 80m/min and 50m/min.

Shearing method of sheet metal cut to length machine: KINGREAL STEEL SLITTER can design various shearing systems for sheet metal cut to length lines, including fly shearing cut to length line, rotary shearing cut to length line, swing shearing cut to length line, and fixed shearing cut to length line.

Material thickness for sheet metal cut to length machine: KINGREAL STEEL SLITTER can customize sheet metal cut to length lines based on customer production needs. KINGREAL STEEL SLITTER light gauge cut to length lines can handle coils from 0.2-3mm, KINGREAL STEEL SLITTER medium gauge cut to length lines from 0.3-6mm, and KINGREAL STEEL SLITTER heavy gauge cut to length lines from 6-25mm.

Price of sheet metal cut to length machine: KINGREAL STEEL SLITTER can design components for different sheet metal cut to length line parameters and performance, depending on the price. For example, loop or pit shearing units can be added to KINGREAL STEEL SLITTER sheet metal cut to length machine; the sheet metal cut to length line can be equipped with two levelers, two stacking tables, etc.; and compact and economical sheet metal cut to length machine solutions can also be customized for customers.

KINGREAL STEEL SLITTER has established a strict quality control process to ensure that every production step meets the standards and requirements. This includes raw material procurement, production process, assembly, testing, etc. To ensure that every part of the sheet metal cut to length machine meets quality standards.

KINGREAL STEEL SLITTER sheet metal cut to length line has also passed the international CE certificate certification.

As a professional cut to length machine manufacturer and supplier, KINGREAL STEEL SLITTER has its own factory in China, and we welcome customers from all over the world to visit our equipment. We have dedicated staff who can provide detailed explanations of the functions and features of each machine. To date, KINGREAL STEEL SLITTER factory has hosted customers from many countries, including the United States, the United Kingdom, Mexico, Indonesia, Qatar, Russia, and Kazakhstan. We look forward to seeing you at our factory!

Contact KINGREAL STEEL SLITTER today to get the latest price list and quotation.

1, What is Stainless Steel Cut To Length Machine?

Stainless steel cut to length machine is an indispensable production equipment in the metal processing industry. It is mainly used to cut metal coils horizontally and cut them into the required width or length.

2, What is Rotary Shearing Cut To Length Machine?

The rotary shearing cut to length machine is mainly used for precision leveling and accurate cutting of metal coils such as copper, stainless steel, aluminum, and iron. The unique advantage of this rotary shearing cut to length line is that it can cut without stopping the machine, avoiding the tiny indentations caused by stopping the rotary shearing cut to length machine for cutting.

3, How does fly shearing cut to length line?

The fly shearing cut to length line is KINGREAL STEEL SLITTER featured machine. In terms of high-precision and high speed cut to length line technology, KINGREAL STEEL SLITTER is not only proficient in thin plates, rotary shears, flying shear fly shearing cut to length machines, but also in heavy duty and medium duty cut to length lines.