KINGREAL STEEL SLITTER offers high precision full auto cut to length lines. These full auto cut to length machines primarily unwind and precisely cut metal coils. And these full auto cut to length lines can achieve speeds of up to 80m/min.

Video About Full Auto Cut To Length Line

Video About Full Auto Cut To Length Line

What is Full Auto Cut to Length Line?

What is Full Auto Cut to Length Line?

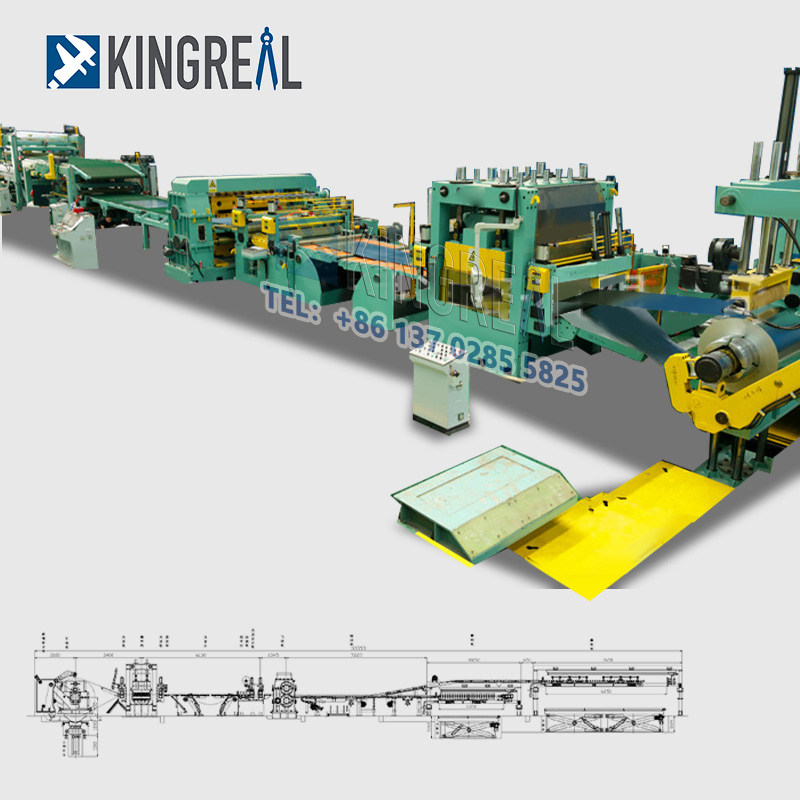

KINGREAL STEEL SLITTER full auto cut to length line is design for cutting the different material coil into the required sheet and stack the profile , which mainly consists of decoiler, clamp leveler, cutter, stacker, etc., and is equipped with auxiliary devices such as feeder, side guide device, transition device, conveyor, etc.

The fully automatic cut to length line designed by KINGREAL STEEL SLITTER only needs to input the required production speed and specified width on the PLC touch screen between operations, and then the automatic production can start.

Workflow of Full Auto Cut to Length Line

Workflow of Full Auto Cut to Length Line

Decoiler with Trolly Car --- Hydraulic Decoiler ---Straigntener---Loop Bridge --- Encode & Measuring Device (with tail plate pinching) --- Cutting Mchine--- Conveyor --- Hydraulic Lift Platform --- Stacker with blower device --- Unload cart

Main Components Detail Of Full Auto Cut To Length Line

Main Components Detail Of Full Auto Cut To Length Line

KINGREAL STEEL SLITTER design the hydraulic cantilever decolier to supports coils and performs uncoiling, which capacity is 15 tons (maximum).

Hydraulic cylinders are used to make the uncoiler retractable and suitable for the coil inside diameter. It is equipped with a cantilever arm.

The 10 0 N.m torque motor drives coil operation in forward and reverse directions, and can also unwind with tension.

Cut to length loop uses 2 sets of eyes to control the speed buffer between the uncoiler and the slitter. T-eyes are controlled by PLC.

Function: It is used to eliminate the different speed and bring the wrong tracked sheet back to the right direction.

At first, the pallets and transition plates are jacked up by cylinders to make the head pass. When working, the transition plate and pallets move down and the plates are stored in the pit.

Full auto cut to length line shearing mode: hydraulic up and down shear, with the feeder direct signal automatic shear

The use of gap adjustment design cutting materials, heat treatment can safely shear 2mm steel plate

Pneumatic stacking of plates, PLC controlled lifting.nThree 0.75kw motors dragging to adjust the width and length.

It is equipped with matching said wind device trumpet With high pressure fan to prevent friction of metal sheet.

Make sure that each hydraulic component is used. The working pressure of the hydraulic system is 6.3-16Mpa.

Advantage Of Full Auto Cut To Length Line

Advantage Of Full Auto Cut To Length Line

- Full automatic production for full auto cut to length line

When a KINGREAL STEEL SLITTER full auto cut to length line is turned on, key components such as the decoiler, straightener, cut-to-length machine, waste collection device, conveyor belt, and stacker automatically work together to efficiently process coils. The full auto cut to length machine can quickly convert coils into sheets, significantly shortening production cycles.

KINGREAL STEEL SLITTER full auto cut to length lines are highly automated, with the entire system managed by a PLC control panel. Users simply enter relevant production parameters, such as the desired number of sheets to be cut, cutting length, and production speed, on the control panel, and the full auto cut to length machine automatically starts and begins operating.

KINGREAL STEEL SLITTER full auto cut to length lines are designed to be user-friendly. To help customers get started quickly, KINGREAL STEEL SLITTER provides detailed video tutorials and operating manuals to ensure every user can quickly master the full auto cut to length machine's operation. Furthermore, upon request, KINGREAL STEEL SLITTER will dispatch professional engineers to the customer's facility for on-site training to ensure that every worker is proficient in full auto cut to length line operation.

To ensure cutting accuracy, KINGREAL STEEL SLITTER has equipped the full auto cut to length machine with a highly stable feeding system, ensuring that the sheets are fed evenly and accurately into the cut-to-length machine. The surface roughness and roundness of the feed rollers are crucial for smooth sheet conveying. If the feed rollers are rough or not round enough, the sheets may vibrate during conveyance, resulting in deviations in the cut dimensions. Furthermore, the stability of the feed motor's driving torque is equally important, as fluctuations in driving torque directly affect the stability of the feed speed. To address this issue, KINGREAL STEEL SLITTER has also equipped the full auto cut to length machine with a precise positioning device to ensure the sheet is correctly positioned before cutting. The accuracy of this positioning device can be adjusted according to the sheet processing requirements, typically achieving a high accuracy standard of ±0.1mm to ±0.5mm.

During the shearing process, sheet flatness directly affects the quality of the finished product. To this end, KINGREAL STEEL SLITTER typically equips the machine with a six-high rollers leveling machine. The more roller layers, the better the leveling effect. For customers with even higher requirements for sheet flatness, KINGREAL STEEL SLITTER can also equip the full auto cut to length line with two levelers, ensuring the sheets undergo two leveling steps before shearing, maximizing the flatness.

KINGREAL STEEL SLITTER full auto cut to length machine is equipped with an advanced stacker, ensuring that cut sheets are automatically transported to a designated location for stacking. This design not only ensures neat stacking but also allows the user to set the stacking quantity.

|

|

|

Reference Date Of Full Auto Cut To Length Machine

Reference Date Of Full Auto Cut To Length Machine

|

Machine Type |

Full Auto Cut To Length Machine |

|

ProductionType |

Full automatic |

|

Material |

Stainless steel, copper strip, silicon steel, cold rolled and hot rolled steel, etc. |

|

Max Coil Thickness |

25mm |

|

Max Coil Weight |

3600mm |

|

Max Coil Height |

30 Ton |

|

Max Cutting Length |

24m |

|

Cutting Speed |

80m/min |

|

Cut Tolerance |

±0.01mm |

FAQ About Full Auto Cut to Length Line

FAQ About Full Auto Cut to Length Line

KINGREAL STEEL SLITTER is a professional manufacturer and supplier. KINGREAL STEEL SLITTER offers full solutions in coil processing and machine tool building, which including high speed cut to length line, simply cut to length machine, fly shearing cut to length machine, swing shearing cut to length machine, fixed shearing cut to length line machine. KINGREAL STEEL SLITTER has a professional team and rich project experience, can provide you with the best service, welcome to contact us.

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct toFoshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

KINGREAL STEEL SLITTER will pick you up at the station or airport.

In order to help our customers to solve machine installation problems, KINGREAL STEEL SLITTER will provide both online and local installation services FOR FREE!