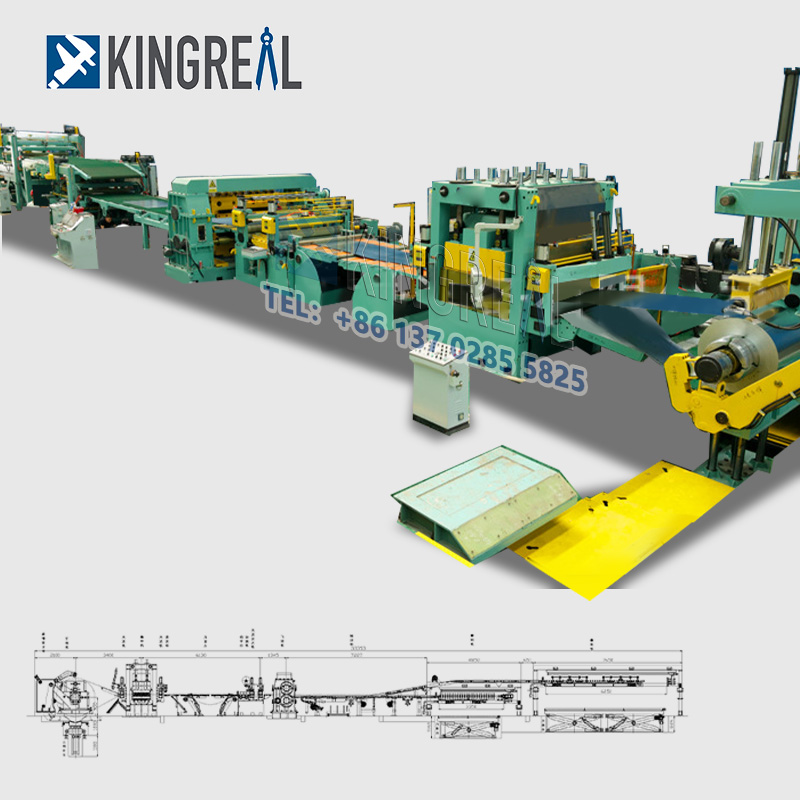

A high speed cut to length line is an advanced piece of equipment that efficiently cuts wide steel coils into sheet metal of the required length. These high speed cut to length lines are widely used in the metal processing industry, specifically for producing sheet metal of various specifications and shapes. A high speed cut to length line typically includes multiple precision components such as a decoiler, leveling machine, cut-to-length machine, stacker, and PLC control system. With continuous technological advancements, the KINGREAL STEEL SLITTER team has comprehensively upgraded high speed cut to length line, introducing a new clamping and feeding system that allows for tolerance control accurate to ±0.010 inches and enables efficient operation at speeds up to 80m/min, producing high-precision sheet metal.

●Why can high speed cut to length lines operate so efficiently?

The high speed cut to length line from KINGREAL STEEL SLITTER operates efficiently primarily due to the following factors:

Advanced Drive System: By employing high-performance servo motors, the machine can move up and down at extremely high speeds. This advanced drive system allows the blades to complete the shearing process in a short time, significantly increasing the number of shearing operations per minute.

Precise Feeding System: To support high-speed shearing, KINGREAL STEEL SLITTER equips high speed cut to length line with a fast and precise feeding system. This system quickly delivers the sheet metal to the shearing position and maintains a stable feeding speed during the shearing process, ensuring continuous and efficient production.

Automated Control: The high speed cut to length line features fully automated control, capable of rapid adjustments based on the thickness and size of the sheet metal. This feature not only improves production flexibility and adaptability but also simplifies the operation process and reduces manpower.

Rapid Start-up and Stop Function: KINGREAL STEEL SLITTER high speed cut to length line can start or stop quickly, reducing equipment setup and downtime. This advantage is particularly suitable for the rapid response requirements of modern manufacturing.

Easy Parameter Adjustment: Operators can quickly adjust shearing parameters, such as shearing length and quantity, without the need for complex mechanical adjustments. This efficient adjustment method significantly saves time and labor costs, bringing convenience to the production process.

In manufacturing, high speed cut to length lines can produce metal sheets of various specifications and shapes, widely used in multiple industries such as metal processing, steel structures, shipbuilding, and electronics manufacturing. Different industries and customers have different requirements for the processing thickness, metal materials, and sheet specifications of the high speed cut to length lines based on the specific needs of their projects.

KINGREAL STEEL SLITTER can customize suitable high speed cut to length line solutions according to customers' actual production needs. Whether it's the need for additional laminating device or the selection of double levelers or double stackers to improve production efficiency, KINGREAL STEEL SLITTER can provide corresponding high speed cut to length line solutions to ensure that different needs are met.

KINGREAL STEEL SLITTER high speed cut to length lines are suitable for processing a variety of metal materials, including steel, stainless steel, aluminum, iron, copper, and PPGI. This versatility makes the high speed cut to length line more flexible in practical applications. Whether the metal sheet thickness ranges from 0.2mm to 25mm, KINGREAL STEEL SLITTER can provide corresponding high speed cut to length lines to meet the production needs of different customers.

To accommodate the cutting of various materials, KINGREAL STEEL SLITTER high speed cut to length lines can be adjusted to meet the needs of different thicknesses, widths, and shapes, ensuring perfect execution of every project.

Cut To Length Machine With Fly Shear enable the cut-to-length machine to accelerate and synchronize with the strip speed, allowing for cutting without stopping the material feed.

KINGREAL STEEL SLITTER has been in the field of cut-to-length shearing lines for more than 20 years, and has a professional technical team to control the quality from the drawing design, manufacturing of machine components, configuration innovation, testing and commissioning of the production line. With independent design capabilities, we are able to provide customized solutions according to the needs of our customers.

KINGREAL SLITTER SLITTING has a wealth of project experience in the cut-to-length production line, according to the customer's actual production needs, the production of three different types of high, medium and economic Coil Cut To Length Line, and more than a dozen countries and regions have reached a long-term and stable cooperation with customers.

- Pre-sale: design drawings and adjust cut to length machine programs according to customers' needs;

- In-sale: Ensure the production quality of the machine, provide testing Cut To Length Line to check the accuracy of the production line running;

- After-sales service: arrange engineers to guide and teach installation in customers' factories.

The flying shear cut-to-length shearing line is an automated production line for metal sheet processing. It can complete high-precision and high-speed cut-to-length shearing process during the continuous operation of the sheet. It is widely used in the steel and non-ferrous metal processing industries.

1/ Dynamic synchronous shearing

The flying shear coil cut to length machine blade completes the shearing when the sheet moves, and the horizontal speed of the shear blade is strictly synchronized with the sheet speed (the error is controlled within ±0.8mm), avoiding efficiency loss caused by downtime.

2/ Length adjustment mechanism

The proportional relationship between the spindle speed and the feeding speed is adjusted through a variable speed gearbox or a continuously variable transmission.

3/ Intelligent control

PLC or frequency converter (such as GD350 series) is used to realize bus communication, store multiple process parameters and adjust the steel coil cutting machine in real time.

4/ Energy saving and efficient design

The continuous operation start-up flying shear saves 1/3-1/2 energy compared to traditional models, and the steel cut to length line speed can reach 100m/min, which is suitable for sheets with a thickness of 0.3-6mm

Fixed shearing cut to length lines feature a feed stop function at a preset length. When the set length is reached, the fixed shearing cut to length line automatically stops, shearing a section of material before restarting to feed the next section of line that needs straightening and cutting.

1/ Simple structural design for fixed shearing cut to length line

The fixed shearing cut to length line features a relatively simple structure and is easy to operate. This feature allows even beginners to quickly master its operation after a brief training session. The simplified structure not only reduces malfunctions but also facilitates routine maintenance.

2/ Suitable for small-scale production

Although the fixed shearing cut to length line can reach speeds of 50m/min, it is not as fast as other high-efficiency shearing methods. Therefore, this fixed shearing cut to length line is particularly suitable for smaller production operations. For companies that do not require large-scale production, the fixed shearing cut to length line can meet their daily production needs, avoiding the resource waste associated with more efficient equipment.

3/ Adaptability to production efficiency

Since the fixed shearing cut to length line has a maximum speed of 50m/min, it is well-suited for customers who do not have high production efficiency requirements. Small fabricators or startups often seek a cost-effective and efficient production solution. In such cases, a fixed shearing cut to length line provides sufficient cutting capacity without placing excessive pressure on the production process.

4/ Suitable for customers with limited budgets

Due to its lower speed and simple design, fixed shearing cut to length lines require relatively low component specifications and performance. This reduces the technical complexity in manufacturing and design, resulting in a relatively affordable price. Therefore, fixed shearing cut to length lines are an ideal choice for customers with limited budgets, especially startups entering the metalworking industry.

Swing shearing cut to length lines are designed to meet customer needs for custom-shaped sheet metal. Through the automatic swing of the shears, the swing shearing cut to length machine can cut at various angles, effectively processing a variety of shapes such as trapezoids, parallelograms, triangles, squares, and rectangles.

1/ Cutting into different shapes

Swing shearing cut to length lines are capable of cutting a variety of shapes. Equipped with a fixed-length clamping mechanism, the swing shearing cut to length machine accurately cuts the moving strip to the desired dimensions. This process ensures that every sheet is precisely tailored to the customer's exacting specifications. The swing shearing cut to length machine incorporates several innovative technologies, including a floating die-holder backlash elimination system, quick die lock, and quick tool change, significantly enhancing shearing efficiency and precision.

2/ Swing cutting motion for swing shearing cut to length line

The swing shearing cut to length line utilizes an swing cutting motion. By optimizing the cutting path, the swing cutting motion ensures high shear quality while improving production efficiency. This innovation enables the swing shearing cut to length line to maintain high-level cutting performance across a wide range of materials, from thin to thick plates.

3/ High speed swing shearing cut to length line

The swing shearing cut to length line boasts a production speed of up to 80 m/min, fully meeting the demands of efficient production. The speed can be flexibly adjusted to suit various production environments and needs.

|

|

|