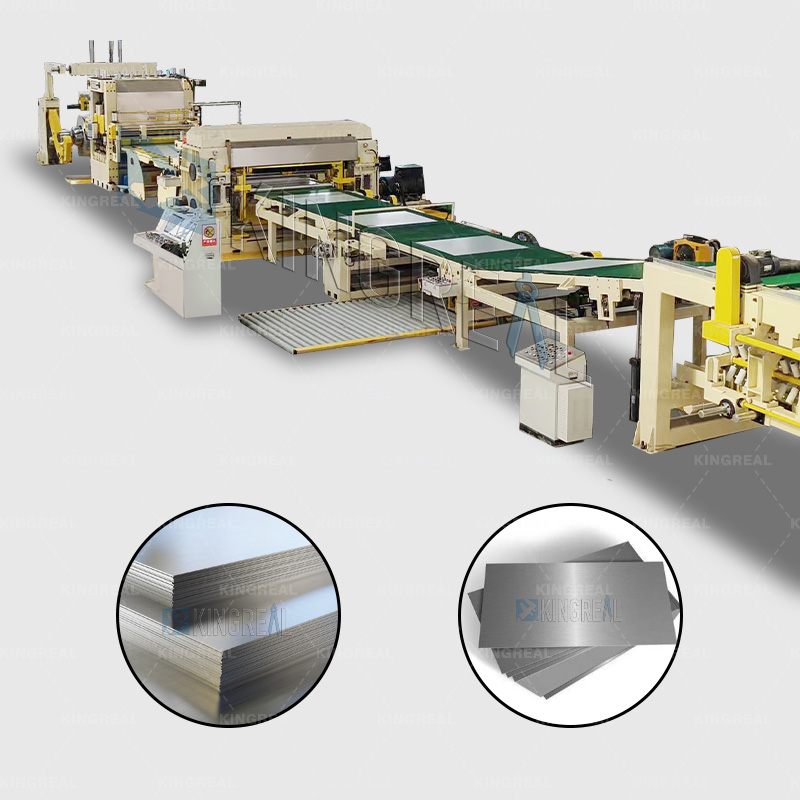

Cut To Length Machine With Fly Shear enable the cut-to-length machine to accelerate and synchronize with the strip speed, allowing for cutting without stopping the material feed.

KINGREAL STEEL SLITTER is a specialized manufacturer and producer in the field of cut-to-length lines and is committed to bringing optimal solutions to its customers.

Depending on the customer's required metal cutting capacity, the range of raw materials to be processed and the plant's production needs.

Cut To Length Machine with fly shear is an industrial machine for cutting continuous metal strips into plates or sheets of specific lengths . KINGREAL STEEL SLITTER design in Fly Shearing

realizes continuous automatic and precise cutting of metal strips without stopping during high speed movement, which speed can up to 80M/Min. It is mainly used in steel,

aluminum, copper and other metal processing industries, and is widely used in automotive, home appliances, construction and other fields.

When the production line is working, decoiler is in feeding state. After sheet material enters the 6 layers 21 rollers high precision leveling machine for leveling, it enters NC Length Measurer by electric eye controlled looper and lateral mechanism. The NC Length Measurer sets size then feeds material to next step Rotate Cutting Machine; when NC feeding reaches the set size. The shearing machine cuts off the sheet material, and the cut sheet material is neatly stacked by the conveying device into the Products Stacking Machine and lifting platform of the stacking steel sheet can automatically decrease with the increase of height of steel sheets; When the set value of plates is reached, production line will automatically stop. At this time, the lifting platform will be lowered by manual control, discharge trolley will be driven out, and another discharge trolley will be driven in at the same time, which will enter the next working cycle.

| Raw Material Table | 1 Unit |

| Trolley for Feeding | 1 Unit |

| Front Auxiliary Support | 1 Unit |

| Uncoiler + Unwinding Device | 1 Set |

| Six-layer-rollers Leveling Machine + Working rollers self-cleaning system | 1 Unit |

| Upper side Film Lamination Machine | 1 Unit |

| Short Looper | 1 Unit |

| Sides Guiding Device | 1 Unit |

| Pinch NC Length Measurer | 1 Unit |

| Fly Shearing Machine | 1 Unit |

| Conveying Machine | 1 Unit |

| Product Stacking Machine | 1 Unit |

| Raw material | CRC STEEL |

| Thickness | 0.4-3.0mm |

| Width | ≤1500mm |

| Coil weight | ≤ 20T |

| Length | 500-6000mm |

| Tolerance of length | L=2m≤±0.3mm(2.0mm) |

| Diagonal tolerance | L=2m≤±0.5mm(2.0mm) |

| Speed | 0~80m/min (Stepless speed regulation) |

| Strip through speed | 0~15m/min |

| Control | AC frequency conversion control |

|

|

|

Advanced servo control system or synchronization control system is used to ensure that the flying shear tool is synchronized with the moving speed of the metal strip.

The control system is able to monitor and adjust the tool speed in real time to accommodate different cutting lengths and strip speeds.

Knives are usually made of high-strength alloy steel or tungsten carbide materials with high hardness and wear resistance to ensure long cutting life and consistent cutting quality.

The shape and angle design of the knives are also optimized to reduce cutting resistance and enhance cutting results.

The knives and tool holders of the flying shear device are dynamically balanced design to ensure smooth operation in high-speed movement, reduce vibration, and improve cutting accuracy and equipment life.

Equipped with a high-precision guiding mechanism to ensure that the flying shear tool always maintains the correct cutting path and position during the cutting process, improving cutting accuracy.