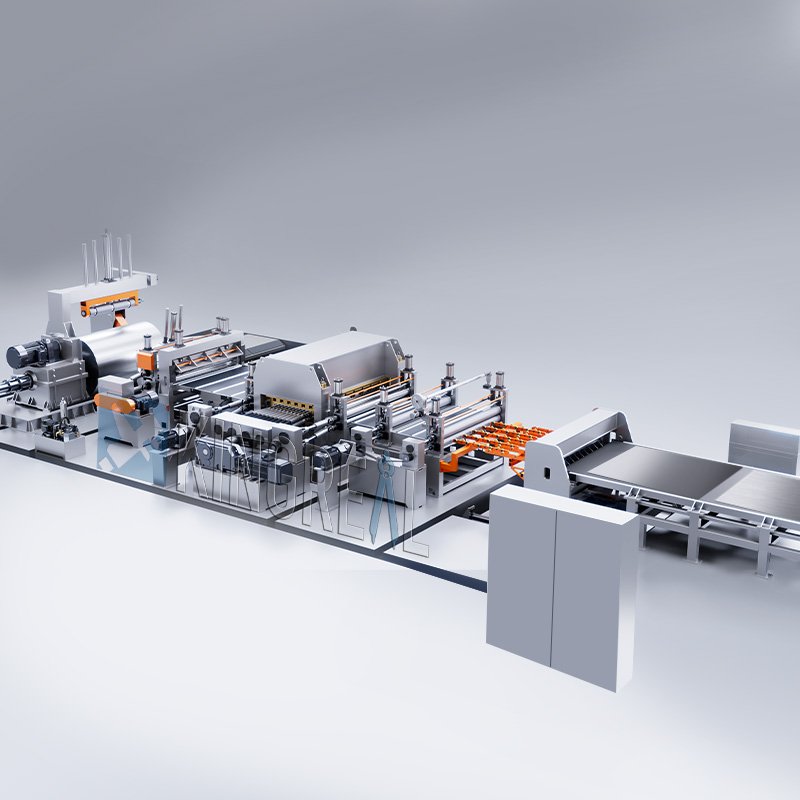

Stainless steel cut to length machine is an indispensable production equipment in the metal processing industry. It is mainly used to cut metal coils horizontally and cut them into the required width or length. With the rapid development of industrialization, the application of stainless steel cut to length line is becoming more and more extensive, especially in the fields of automobile manufacturing, building materials processing and metal component manufacturing. In this article, KINGREAL STEEL SLITTER will discuss with you in detail the working principle, type, application, operation and maintenance of stainless steel cut to length machine and the considerations for purchase.

|

1. Feeding for stainless steel cut to length machine In the initial stage of stainless steel cut to length line, raw materials are fed into the stainless steel cut to length machine and will go through a leveling process. The purpose of this step is to level the surface of metal coils to ensure the accuracy and quality of subsequent cutting.

2. Horizontal cutting for stainless steel cut to length line The cutting machine is the core part of the stainless steel cut to length machine. Metal sheets or coils are precisely cut horizontally in this equipment to reach the required width or length. KINGREAL STEEL SLITTER stainless steel cut to length line uses a well-known brand of servo system to drive the cutting machine to ensure excellent equipment performance and high shearing accuracy. According to customer needs, the stainless steel cut to length machine can realize the shearing service of multi-specification plates to meet the customized needs of different users.

3. Stacking and Packaging for stainless steel cut to length line The cut metal sheets are stacked or loaded for the next transportation or processing. This process usually includes an automated stacking system to improve work efficiency and reduce manual intervention. |

|

(1)Longitudinal length tolerance:

L0 = 1mm ± 0.3mm (constant speed)

L1 = 1mm ± 0.4mm (acceleration and deceleration)

(2)Diagonal length tolerance:

L1 = 2mm ± 0.5mm

Sickle bend: ≤0.05mm

Burr: ≤0.05mm or not more than 4% of the plate thickness

(3)Aggregate length:

First receiving machine: 300-3000mm

Second receiving machine: 300-5000mm

*In order to ensure that the stainless steel cut to length machine can produce high-quality metal sheets, KINGREAL STEEL SLITTER quality inspection personnel will measure and test the thickness, length, width and diagonal of the sheet to ensure that the surface of the sheet is flat, the burr is small, and there is no obvious wave and warping.

Based on the diverse production needs of customers, KINGREAL STEEL SLITTER provides a variety of stainless steel cut to length machine manufacturing solutions. The stainless steel cut to length line special solutions that are widely praised by customers include the following:

1. According to the thickness of the coil

Different thicknesses of metal coils require different types of stainless steel cut to length machines to ensure the optimal cutting effect.

Light gauge cut to length machine: This Light gauge cut to length machine can handle metal coils with a thickness of 0.3-3mm. Its design focuses on the fast cutting of thin and light materials, and is suitable for the production of light metal products such as electronic product housings and decorative materials. This type of stainless steel cut to length line is usually equipped with a high-precision servo drive system, which can achieve fast and stable cutting to meet high-frequency production needs.

Medium gauge cut to length machine: It can handle metal coils with a thickness of 0.3-6mm and is suitable for a wide range of industrial applications. This type of stainless steel cut to length machine is designed with higher cutting accuracy and flexibility in mind, and can cope with the processing needs of various materials. Medium gauge cut to length machines are usually used in industries such as automotive parts and mechanical equipment housings, and can provide higher production efficiency while ensuring cutting quality.

Heavy gauge cut to length machine: This type of stainless steel cut to length line can handle metal coils with a thickness of 6-20mm, mainly for heavy industrial applications such as shipbuilding, steel structure engineering, etc. This type of stainless steel cut to length line has strong cutting ability and stability, can handle relatively hard materials, and ensures good performance under high-load working conditions.

|

|

|

2. According to the shearing method

Flying shearing cut to length machine: This shearing method allows non-stop shearing, with extremely high speeds of up to 80m/min, which greatly improves production efficiency. Flying shearing cut to length machines are particularly suitable for mass production and can quickly complete continuous cutting tasks. They are widely used in areas that require high output, such as automobile manufacturing and home appliance industries. Its high efficiency allows companies to complete more orders in a shorter time and improve overall production capacity.

Swing shearing cut to length machine: Similar to the flying shear, the swing shearing cut to length machine also keeps the machine running during the shearing process, and the speed can also reach 80m/min. This stainless steel cut to length line is particularly suitable for processing irregular plates and can flexibly respond to various complex shearing needs. The swing shearing cut to length line performs well in processing some special-shaped metal components, helping companies achieve greater product diversity and flexibility.

Fixed shearing cut to length machine: This shearing method has a relatively slow speed of up to 50m/min, which is suitable for customers with small production scale or low production efficiency requirements. The advantage of the fixed shearing cut to length machine is its high-precision cutting, which is suitable for industries that require fine processing, such as small machinery manufacturing and the production of special customized products. Despite the slow speed, its advantage in precision makes it a preferred solution for certain specific markets.

|

|

|

3. Customized solutions for stainless steel cut to length machine

In addition to the above categories, KINGREAL STEEL SLITTER also provides customized stainless steel cut to length machine solutions to meet the unique needs of specific industries or customers. By communicating in-depth with customers and understanding their production processes and specific requirements, KINGREAL STEEL SLITTER is able to design more accurate stainless steel cut to length machine solutions. This customization is not only reflected in the technical parameters, but may also include equipment configuration, degree of automation, operation interface and other aspects to ensure that each customer can get the most suitable production equipment for themselves. For example, stainless steel cut to length lines with laminating devices, stainless steel cut to length lines with double leveling machine and stainless steel cut to length machines with double stacking machine are all KINGREAL STEEL SLITTER unique personalized stainless steel cut to length line manufacturing solutions.

|

|

|

The application range of stainless steel cut to length machines is extremely wide, mainly including the following fields:

Metal processing industry: Cutting cold-rolled plates, hot-rolled plates, galvanized plates and other metal materials to a fixed length.

Manufacturing industry: Widely used in automobile manufacturing, building materials processing, metal component manufacturing and other fields.

1. Operation of stainless steel cut to length machine

The personnel operating the stainless steel cut to length machine need to be familiar with the control system and operating procedures of the equipment, strictly follow the safety operating procedures, and ensure the safety and smoothness of the production process.

2. Maintenance of stainless steel cut to length machine

It is very important to maintain the stainless steel cut to length machine regularly, including cleaning, lubrication and inspection of mechanical parts. Regular maintenance can ensure the stable operation of the equipment and extend its service life.

When purchasing a stainless steel cut to length machine, users need to consider the following factors:

1. Cutting requirements

Choose a suitable stainless steel cut to length machine according to the type, thickness and size of the metal material to be cut. Different materials and thicknesses require different types of equipment to ensure the best cutting effect.

2. Production capacity

Consider the production capacity and efficiency requirements of the stainless steel cut to length line and choose equipment of appropriate specifications. The assessment of production capacity can help users choose the right stainless steel cut to length machine to meet daily production needs.

3. Quality and reliability

It is crucial to choose a reliable stainless steel cut to length line manufacturer or brand to ensure the stability and continuous production capacity of the stainless steel cut to length machine. High-quality stainless steel cut to length machine can not only improve production efficiency, but also reduce failure rate and downtime.