KINGREAL STEEL SLITTER Stop To Shearing Cut To Length Line is suitable for customers who do not have high requirements for production efficiency. The fixed shearing cut to length line needs to be stopped during cutting and the maximum speed is 50m/min.

Video About Stop To Shearing Cut To Length Line

Video About Stop To Shearing Cut To Length Line

Description Of Fixed Shearing Cut To Length Line

Description Of Fixed Shearing Cut To Length Line

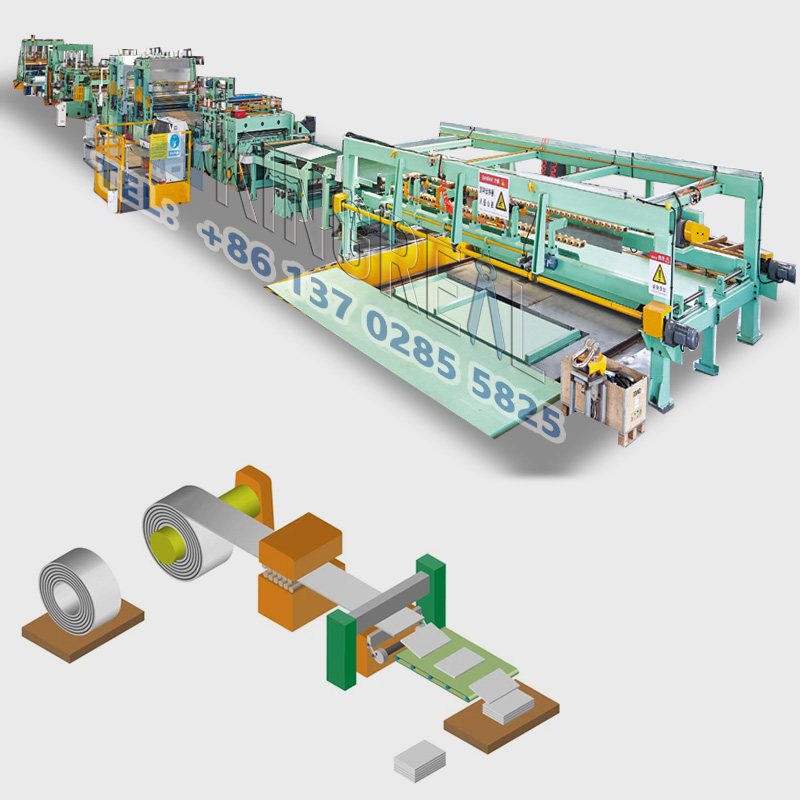

KINGREAL STEEL SLITTER fixed shearing cut to length line is design for takes the main rolls of different materials, decoiler, straightener and cuts them into sections of precise length, then stacks the sheets into bundles.

According to the production needs of different products of customers, KINGREAL STEEL SLITTER will customize fixed shearing cut to length lines suitable for different widths, thicknesses and weights of incoming coils.

KINGREAL STEEL SLITTER metal cut to length machine has different shearing type, such as fixed shearing cut to length line, fly shearing cut to length line and rotary shearing cut to length line, swing shearing cut to length line etc. For this fixed shearing cut to length line, low price and short production time are the main advantages. As a traditional production line, be the conservative choice for most factory.

KINGREAL STEEL SLITTER Fixed Shearing Cut To Length Line Procedure

KINGREAL STEEL SLITTER Fixed Shearing Cut To Length Line Procedure

Trolley for coil loading -- Hydraulic Decoiler -- Guiding&Pressing Unit -- 2 Pinch Rolls Leveling Machine -- Pit -- Sheet Transmission Table -- Stop To Shearing Machine -- Auto Stacker

Specification Of Fixed Shearing Cut To Length Line

Specification Of Fixed Shearing Cut To Length Line

|

Machine Type |

Cut to length machine |

|

Max Coil Thickness |

25mm |

|

Max Coil Widths |

3600mm |

|

Max Coil Weight |

20Ton |

|

Main Coil Cut Length |

25mm |

|

Shearing Type |

Stop to shearing |

|

Shearing Speed |

60m/min |

|

Cut Tolerance |

±0.01mm |

Equipment List Reference Of Fixed Shearing Cut to Length Machine

Equipment List Reference Of Fixed Shearing Cut to Length Machine

|

Name |

No |

|

Entry coil car |

1 set |

|

Decoiler |

1 set |

|

Feeding table |

1 set |

|

Leveling |

1 set |

|

Loop table |

1 set |

|

Side guide |

2 Pair |

|

Servo feed roll |

1 PC |

|

Shearing machine |

1 PC |

|

Stacking machine |

1 set |

|

Electrics |

1 set |

Feature Of Fixed Shearing Cut To Length Line

Feature Of Fixed Shearing Cut To Length Line

|

1.Fixed shearing cut to length line is cheaper than other shearing type cut to length machine. 2.The fixed shearing cut to length line is activated to produce the sheet or billet to a predetermined length. The strip runs quickly through the line, then slows down and comes to a complete stop. 3.Small footprint. Since the fixed shearing cut to length line design is shorter than others, a tight line configuration may be a good choice if floor space is limited within the factory. 4.The base site cost is low. Since the fixed shearing cut to length line does not require an annular pit, base costs are low, and the gauge capacity of the take-up machine is virtually unlimited, making it ideal for heavy-duty applications. Tightening machine with stationary shear for the lowest cost of all cross-cutting lines |

|

KINGREAL STEEL SLITTER warmly invites customers from around the world to visit our factory for a fixed shearingcut to length machine tour. Here, customers can learn all about KINGREAL STEEL SLITTER fixed shearingcut to length machines, operate them themselves, and inspect finished products. This is the fastest and most effective way to gain a deeper understanding of our fixed shearingcut to length machines and the most intuitive way to assess whether they meet your specific production needs. KINGREAL STEEL SLITTER staff will accompany customers throughout the tour and provide a professional introduction to KINGREAL STEEL SLITTER fixed shearingcut to length machines.

|

|

|

FAQ

FAQ

KINGREAL STEEL SLITTER is a professional manufacturer and supplier.

KINGREAL STEEL SLITTER offer full solutions in coil processing and machine tool building, which including fly shearing cut to length machine, steel cut to length machine, full auto cut to length machine, etc.

KINGREAL STEEL SLITTER have a professional team and rich project experience, can provide you with the best service, welcome to contact us.

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?

KINGREAL STEEL SLITTER have specialized in this industry for over 20 years, especially in coil processing equipment.

KINGREAL STEEL SLITTER machine lines are exported directly to Russia, Vietnam, India, Indonesia and many other countries in Asia, Africa, Middle East and South America.

1/Unveiling the Sheet Metal Cut To Length Machine: A Complete Analysis of Quality and Process

2/The Comprehensive Guide to Steel Cut to Length Machine

3/Basic Configuration of Simply Cut To Length Line

4/Troubleshooting of cutting deviation on Stainless Steel Cut To Length Lines

5/Cut to length line machine: new generation of fully automated solutions