In modern manufacturing, cut to length line machines are essential equipment, widely used in industries such as home appliances, automobiles, and building materials. Their primary functions are to unwind, straighten, and shear metal strip to specified dimensions, then neatly stack the resulting sheets. With the advancement of society and technology, a new generation of fully automated metal cut to length line manufacturing solutions has emerged. Compared to traditional standard or semi-automatic cut to length line machines, these fully automated metal cut to length lines can be flexibly adjusted to meet the processing needs of various scales and metal materials, significantly improving production efficiency and product quality.

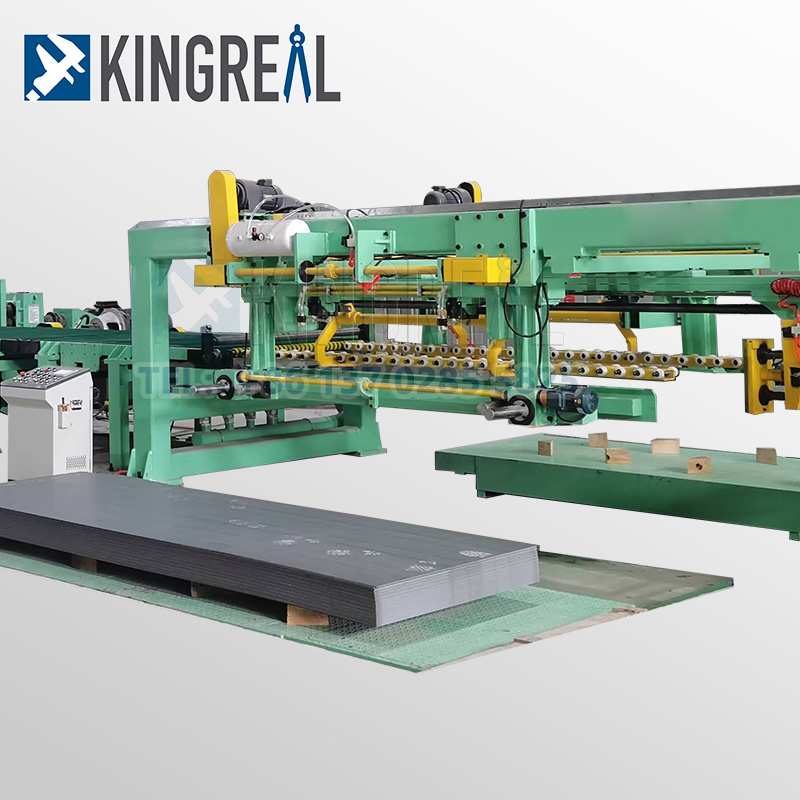

A cut to length line machine primarily consists of a loading trolley, decoiler, leveling machine, feeder, shearing machine, conveyor, and stacker. A shearing machine is a high-performance, integrated mechanical, electrical, and hydraulic system suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various other metal materials after coating. Metal cut to length line features a high degree of automation, simple and reliable operation, high cut-to-length accuracy, high sheet flatness, and neat stacking. During the production process of a cut to length line machine, the decoiler unwinds the metal coil and then passes it through a leveling machine to ensure the flatness of the metal strip before shearing. A feeding mechanism delivers the leveled metal strip to the shearing machine for shearing, which precisely cuts the strip to the specified dimensions. Finally, a conveyor transports the sheared sheets to the stacking device for neat stacking.

With the advent of Industry 4.0, cut to length line machine manufacturing has entered a new era. KINGREAL STEEL SLITTER engineers design fully automatic metal cut to length lines with various parameters and configurations based on specific customer needs. This new generation of fully automatic cut to length line machines can be flexibly adjusted to meet the needs of both large-scale and small-scale production. For example, for fixed-length shearing, conventional mechanical and electrical coordination, digital frequency conversion technology, or AC servo technology can be used to achieve high-precision shearing operations. The shearing machine selection is also very flexible, with options available for conventional mechanical and hydraulic models, as well as high-speed gate shears powered by electromagnetic or pneumatic clutches. This diverse configuration allows the metal shearing line to handle a wide range of complex production tasks.

●Customization options of metal cut to length line

In its new generation of fully automatic cut to length line machines, KINGREAL STEEL SLITTER offers a variety of customization options to meet specific customer needs.

●Surface protection for metal cut to length line

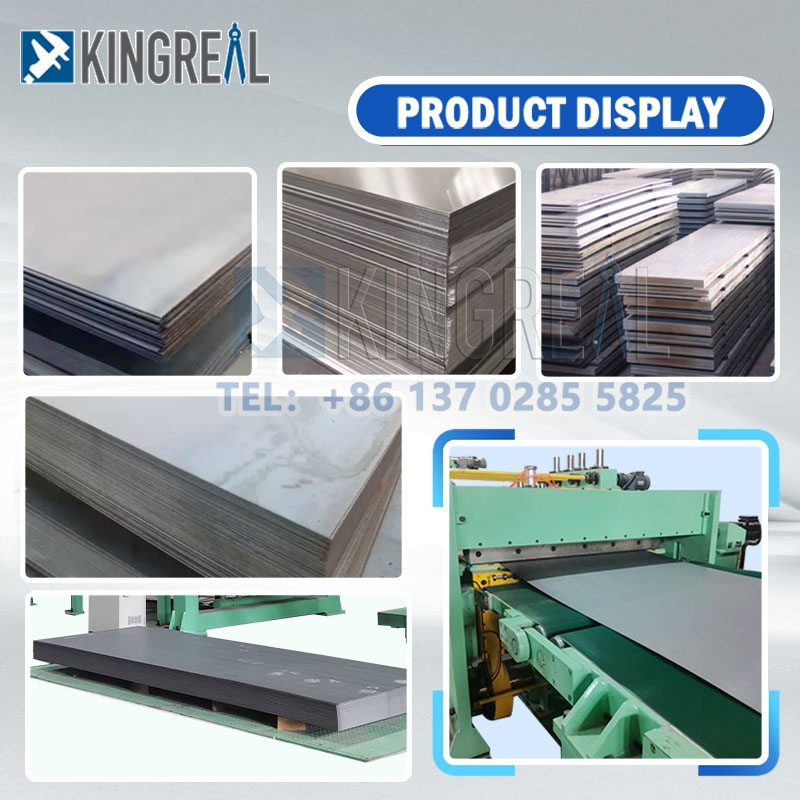

For customers who require a scratch-free sheet metal surface, KINGREAL STEEL SLITTER recommends equipping the cut to length line machine with a laminating device. This device applies a protective film to the metal coil surface, ensuring that it is protected from blade scratches and other surface damage during the shearing and feeding processes. This design not only improves the product's appearance but also reduces product scrap rates due to surface defects.

●Flatness requirements for metal cut to length line

For customers with stringent flatness requirements, KINGREAL STEEL SLITTER can equip the cut to length line machine with two leveling machines. The metal coil undergoes two leveling steps before being fed to the shears for precise shearing. This double leveling design effectively improves the flatness of the metal sheet, ensuring the quality of the final sheared product.

●Efficient stacking for metal cut to length line

To meet the requirements of efficient production throughout the entire process, KINGREAL STEEL SLITTER can also equip cut to length line machines with two stackers to automatically stack cut metal sheets. This design significantly increases production automation and reduces manual intervention, improving efficiency while also reducing operational risks.

|

|

|

The new generation of fully automatic cut to length line machines offers several technical advantages. Firstly, they offer high efficiency. The increased level of automation enables the metal cut to length line to quickly respond to production demands, reducing downtime and labor costs. Secondly, precise shearing and leveling technology ensures high product quality standards and reduces rejects. Furthermore, flexible customization options allow each cut to length line machine to be tailored to the specific production environment and customer needs, enabling personalized production.

Cut to length line machines are widely used in various industries, including home appliances, automotive, and construction. In the home appliance industry, metal cut to length lines are responsible for producing various metal casings and inner shells, ensuring the product's aesthetics and durability. In automotive manufacturing, cut to length line machines are used to produce body parts and chassis, ensuring their structural strength and safety. In the construction industry, metal cut to length lines provide precise shearing services for various building materials, supporting the diverse needs of modern architecture.

Cut to length line machine technology will continue to evolve, with automation and intelligence becoming key trends. Future metal cut to length lines will achieve higher levels of intelligent control and data analysis, thereby improving production efficiency and product quality. KINGREAL STEEL SLITTER launch of a new generation of fully automated cut to length line machine manufacturing solutions is providing more efficient and precise production support across various industries. Whether in the home appliance, automotive, or construction industries, the widespread application of metal cut to length lines is continuously driving industry progress and development.

|

|