"In the modern metalworking industry, full auto cut to length lines, as a crucial piece of coil processing equipment, are playing an increasingly important role. This full auto cut to length machine efficiently produces high-precision metal sheets that meet customer requirements and is widely used in a variety of fields, including industry, construction, shipbuilding, and electronics. With technological advancements, the efficiency and precision of full auto cut to length lines are continuously improving."

Introduction to Full Auto Cut to Length Line

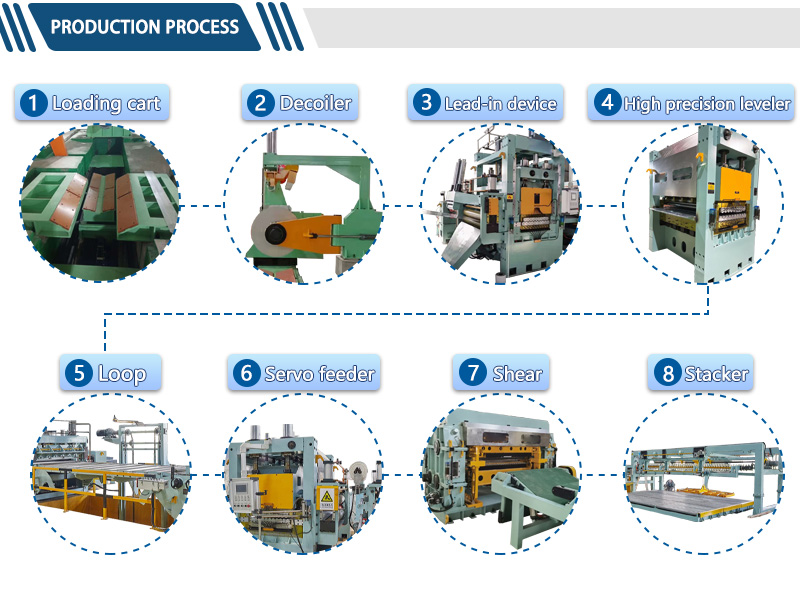

The core function of a full auto cut to length line is to uncoil, level, and cut metal coils into flat sheets of specified lengths. This process not only involves the coordinated operation of multiple mechanical components but also requires a high degree of automation and precise control. The full auto cut to length machine's main components include a decoiler, leveling machine, feeder, cut-to-length machine, and stacker. These components work seamlessly together to cut coils into flat sheets that meet precise length specifications, significantly improving production speed and accuracy.

Capable of processing large quantities of metal sheets, full auto cut to length machines not only shorten production cycles but also improve production efficiency, meeting customer demands for high-volume, high-precision products.

Workflow of Full Auto Cut to Length Line

1. Uncoiling For Cut To Length

During the uncoiling stage, the metal coil is placed on the decoiler and gradually unwound as it moves through the full auto cut to length machine. The decoiler's design ensures smooth unwinding of the coil, preventing any problems during subsequent processing. The uncoiling process must be performed without twisting or damaging the coil.

2. Leveling For Metal Cut To Length

Leveling is a crucial step in ensuring sheet quality. The leveler effectively flattens the sheet, eliminating any bends or imperfections. Levelers are typically equipped with high-precision sensors to monitor the sheet's condition in real time and ensure it meets design standards. This step is crucial for the subsequent shearing process, as even the slightest error can impact the quality of the final product.

3. Feeding For Auto Cut To Length

The leveled sheet is fed into the shearing unit via a feeding system. The precise control of the feeder ensures that each sheet reaches the cutting position accurately, thereby improving production efficiency. A well-designed feeding system reduces downtime and ensures continuous operation of the production line.

4. Cut To Length

During the cutting stage, the full auto cut to length line cuts the sheet into the desired length according to pre-set dimensions. The precision of this process directly determines the yield rate of finished products. Shears in full auto cut to length machines typically utilize advanced cutting tools and control systems to ensure high precision with every cut. Modern full auto cut to length line also feature automatic adjustment capabilities, adapting to varying sheet materials and thicknesses.

5. Stacking For Auto Cut To Length

The cut sheets are neatly stacked, ready for further processing or transportation. The stacker design ensures stability during stacking, preventing damage during transit or storage.

Different Full Auto Cut to Length Line Solutions

"To meet diverse customer needs, KINGREAL STEEL SLITTER offers a variety of customized full auto cut to length machine solutions. The following are the main categories:"

1. By Metal Material

KINGREAL STEEL SLITTER full auto cut to length lines can process a wide range of materials, including steel, stainless steel, aluminum, copper, cold-rolled, hot-rolled, and PPGI. Some full auto cut to length machines are designed specifically for processing a single material, while others can handle multiple materials. This flexible design allows customers to select the appropriate equipment based on their specific needs.

2. By Plate Thickness

KINGREAL STEEL SLITTER full auto cut to length lines are categorized according to plate thickness into thin, medium, and thick plate full auto cut to length machines:

Light gauge cut to length line: Suitable for processing coils with a thickness of 0.2-3 mm.

Medium gauge cut to length line: Suitable for processing coils with a thickness of 0.3-6 mm.

Heavy gauge cut to length line: Suitable for processing coils with a thickness of 6-25 mm.

Whatever the customer's needs, KINGREAL STEEL SLITTER ensures that it provides the appropriate full auto cut to length line to meet the processing requirements of each type of coil.

3. By Shearing Method

KINGREAL STEEL SLITTER offers a variety of shearing methods, including fly shearing cut to length line, rotary shearing cut to length line, swing shear cut to length line, and fixed shearing cut to length line. The fly shearing cut to length line is one of KINGREAL STEEL SLITTER most popular full auto cut to length machines, offering the advantages of high shearing speeds, reaching speeds of up to 80 m/min, and requiring no downtime during shearing, greatly improving production efficiency.

4. Customized Requirements

To meet customers' specific production needs, KINGREAL STEEL SLITTER engineers can customize full auto cut to length lines equipped with dual levelers, dual stackers, and laminating devices:

Full auto cut to length machines with dual levelers: perform a double leveling process on coils, significantly improving sheet flatness.

Full auto cut to length lines with dual stackers: enhance efficiency and automation throughout the entire production process, reducing manual intervention.

Full auto cut to length machines with laminating devices: effectively prevent blade scratches on the sheet surface, protecting product quality.

Applications of Full Auto Cut to Length Machine

"Full auto cut to length lines have a wide range of applications across multiple industries. The following are some key areas of application:"

1. Full auto cut to length line in automotive industry

In automotive manufacturing, full auto cut to length machines are used to produce sheet metal for automotive parts, frames, and other structural components. With the rapid development of the automotive industry, the demand for materials is increasing. Precision full auto cut to length machines can provide the high-quality metal parts required for automotive manufacturing.

2. Full auto cut to length line in construction industry

In the construction industry, full auto cut to length machines are used to manufacture structural components and building materials. Whether it's reinforced concrete or lightweight steel structures, full auto cut to length lines can provide the necessary metal sheets to meet architectural design requirements. Through efficient shearing processes, the production cycle of building materials is significantly shortened.

3. Full auto cut to length line in home appliance manufacturing

The home appliance industry also has a significant demand for metal sheets. Full auto cut to length machines are widely used to produce the metal casings and internal structures of appliances such as refrigerators, washing machines, and ovens. High-quality metal sheets not only enhance the product's aesthetics but also its durability.

4. Full auto cut to length line in aerospace

In the aerospace sector, full auto cut to length machines are used to cut the high-precision sheet metal required for aircraft manufacturing. Aerospace products have extremely high requirements for material strength and precision, and full auto cut to length lines can provide standard-compliant sheet metal to ensure flight safety.

5. Full auto cut to length machine in metal furniture

In the production of metal furniture, full auto cut to length machines provide metal sheets for furniture frames and other structures. As consumers' expectations for home quality continue to rise, market demand for metal furniture is also growing, and precision full auto cut to length lines can meet this market demand.