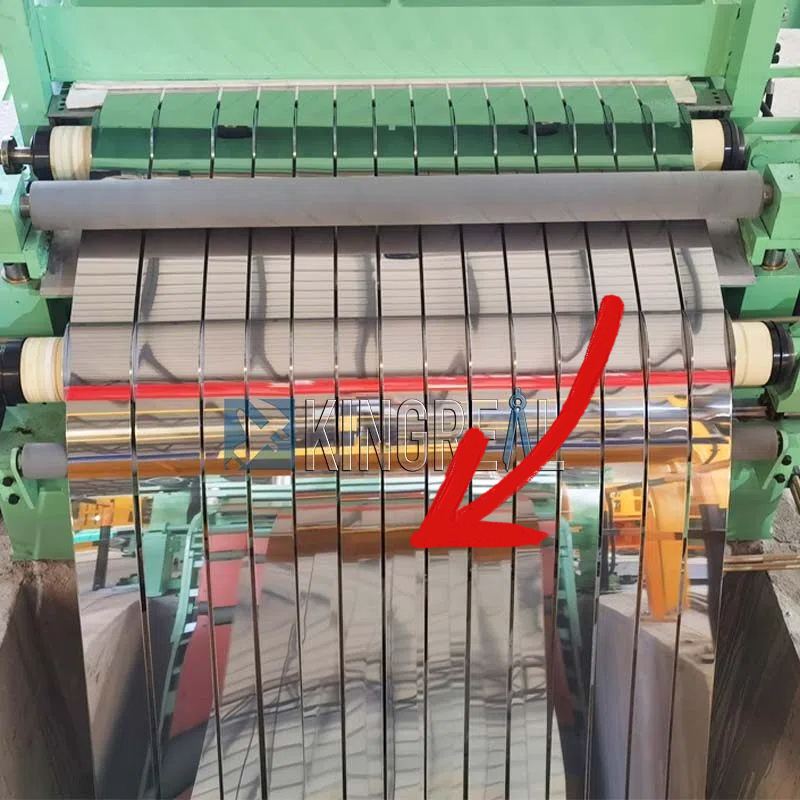

One of the most important factors for guaranteeing the quality of narrow strips is precise slitting. Whether stainless steel, steel, aluminum alloy, copper, PPGI, cold-rolled, or hot-rolled, keeping tight tolerances during slitting is immediately connected to product quality, downstream processing efficiency, and customer satisfaction. Narrow strips might be rejected even for small differences in slit width, edge defects, or changes in material curvature.

So, how can you properly operate a steel strip slitting line to achieve tight tolerances? This article examines five key aspects: steel strip slitting machine setup, tension control, tool configuration, material handling, and steel strip slitting line maintenance.

The initial setup of the steel strip slitting machine is fundamental to achieving slitting tolerances. Five key aspects must be addressed before startup:

-Steel Strip Slitting Line Alignment: Before running material, check the alignment of the mandrel (to ensure accurate core operation), the slitting axis (parallel to the unwind/rewind axis), and the steel strip slitting machine base. Laser alignment tools are used to ensure precise component positioning to avoid errors caused by misalignment.

-Magnetic Core Selection and Installation: Select a circular, straight magnetic core with an inner diameter that matches the steel strip slitting machine shaft. Ensure it is securely installed to prevent slippage or deformation. Core concentricity mistakes can travel to the slitting aperture, hence compromising edge quality and width accuracy.

-Tool Positioning: Precisely adjust the tool position to determine the slitting width according to order specifications using a calibration meter or a verified digital readout for the steel strip slitting line. Check before startup to ensure the tool is locked in place to prevent shifting and causing deviation.

-Roll Guide: Adjust the initial guide position to center the roll before entering the slitting area to prevent uneven tension and cutting deviation, ensuring dimensional stability.

-Program Verification: If the steel strip slitting machine is programmable, confirm that the correct program is loaded and that parameters such as the tension curve and slitting speed meet operating requirements to avoid parameter errors that could affect tolerances.

|

|

Stable tension is key to slitting tolerances and requires management in four key areas:

-Tension Consistency: Maintain uniform tension throughout the steel strip slitting machine process, from unwinding, slitting, to rewinding. Material width changes, stretching, edge ripples, bowing, and tolerances are all severely affected by stress change.

-Zone Control: Modern steel strip slitting lines have independent tension zones for unwinding, slitting, and rewinding. The load cells and tension regulators must be regularly calibrated.

-Tension should be set based on material characteristics: too low can lead to slippage and poor tracking; too high can stretch the material, causing edge deformation.

-Rewinding: For compressible materials, a higher tension is applied at the core, gradually decreasing as the roll diameter increases to ensure a stable roll without stretching. Improper taper can cause edge damage, uneven winding, and compromise width consistency.

-Material Knowledge: Different materials require different stretching strategies. Knowing the elastic modulus and yield strength of the material is essential so that a suitable tension scheme may be devised to avoid material damage or tolerance violations.

Tool settings determine cut quality and dimensional accuracy, focusing on four key aspects:

-Tool Sharpness: A dull tool can squeeze or tear the material, creating burrs and violating tolerances. To maintain sharp edges, a tool sharpening/replacement schedule based on the material's wear features and processing cycle should be set.

-Tool Type and Slitting Method: Select tools based on the material and cut requirements. Choose between a fly shearing (continuous high-speed), rotary shearing (high-precision), or fixed shearing (intermittent small-batch) based on customer needs to ensure tolerances.

-Angle Optimization: For razor-type steel strip slitting machines, adjust the blade angle according to the material to balance cut quality with tool wear. Fine-tune the gap and overlap between the top and lower blades for shear-type steel strip slitting lines (consult the manufacturer's chart and take into account material qualities). Improper gap or overlap can cause burrs and rough edges.

-Operational Stability: Ensure that the steel strip slitting machine's blade carriage is parallel to the blade axis and that radial runout of the rotary blade is minimized to avoid "chatter" marks and unstable edge quality.

|

|

Standardized material handling can prevent material-induced tolerance variations. Focus on four key areas:

-Joint Integrity: Use strong, uniformly thick joints to avoid joint failure or excessive thickness that can cause equipment jamming, tension fluctuations, and damage to the cut edge.

-Edge Guidance: Active web guides are used to ensure the web is centered in the slitting area, preventing web deviation resulting in uneven width and poor outer strip edge quality.

-Roll Handling: Use cranes and shaft hoists to load and unload rolls. Avoid impacts or drops that could damage the core and affect the concentricity of the steel strip slitting line installation. Handle finished rolls carefully to prevent edge damage and deformation.

-Debris Management: Keep the slitting area clean and remove debris promptly to prevent it from deflecting the web, interfering with the cutter, or becoming lodged in the roll, impacting quality and tolerances.

Maintenance ensures stable steel strip slitting line operation and tolerance accuracy by focusing on five key areas:

-Preventive Maintenance: Check component alignment, bearings, belt tension, gear wear, and pneumatic/hydraulic systems according to the manufacturer's schedule, and address potential issues promptly.

-Lubrication Management: Lubricate according to the specified time, amount, and type to avoid over-lubrication (poor heat dissipation) or under-lubrication (high friction) that can cause component wear and vibration.

-Component Wear Inspection: Regularly inspect key components such as bearings, shafts, and gears, and promptly replace any severely worn components to prevent vibration, slippage, and misalignment from affecting tolerances.

-Calibration and Maintenance: Regularly calibrate tension sensors, load cells, and digital positioning systems to prevent measurement errors caused by uncalibrated instruments, which can affect parameter settings.

-Cleaning: Clean the steel strip slitting machine from dust, grease, and debris, especially around bearings, guide rails, and sensors, to ensure smooth operation and facilitate problem detection.