A coil cut to length machine is a highly efficient coil processing line used primarily to cut large coils of metal into precisely cut lengths of sheet metal. Particularly in the automobile industry, where it is absolutely necessary, this coil cut to length line is very popular across several industrial areas. Offering manufacturers high-precision, high-efficiency manufacturing solutions, coil cut to length machines can handle a broad spectrum of materials including steel, aluminum, stainless steel, copper, and PPGI. The functioning mechanisms, benefits, and particular automotive manufacturing uses of coil cut to length lines will be discussed in this article.

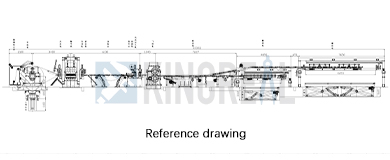

A coil cut to length line is an automated production line designed to uncoil, level, and cut metal coils into precisely cut lengths. Coil cut to length machine’s main components include a decoiler, leveling machine, feeder, shear, and stacker. These precision components work together to efficiently convert coils into standard flat sheets. For companies with strict demands for production accuracy and efficiency, coil cut to length lines are especially crucial. Particularly for large-scale manufacturing, fully automated, high-speed coil cut to length machine can provide great financial advantages.

The workflow of a coil cut to length machine can be divided into several key steps:

Uncoiling: The coil is placed on the decoiler and gradually unwound as the coil cut to length line operates.

Leveling: The unwound sheet passes through a leveler to eliminate any surface bends or imperfections, ensuring a smooth surface.

Feeding: The leveled sheet is fed into the shearing unit for cutting.

Cutting: The shear cuts the sheet into the desired length according to preset dimensions.

Stacking: After cutting, the sheets are neatly stacked for further processing or shipping.

This highly automated process ensures that each sheet meets the specified length requirements, thereby improving overall production efficiency and reducing material waste.

1. Precision coil cut to length line

The coil cut to length machine's control system allows the machine to automatically identify the coil length and accurately cut the sheet simply by setting the production parameters on the control panel. This high-precision cutting method significantly reduces errors and ensures product consistency.

2. Efficient coil cut to length line

Modern coil cut to length machines can achieve production speeds of up to 80m/min, significantly improving production efficiency and shortening production cycles. High automation not only saves time but also reduces labor costs.

3. Highly flexible coil cut to length line

Coil cut to length machines can process a wide range of metal coils with thicknesses ranging from 0.2 mm to 25 mm, thus meeting the needs of diverse projects. Whether thick or thin, coil cut to length lines offer an excellent cutting solution.

4. Reduced waste for coil cut to length machine

By providing precise cuts to length, coil cut to length lines effectively reduce waste, thereby lowering production costs. This advantage is particularly important in today's increasingly resource-constrained world.

|

|

|

Coil cut to length machines are ubiquitous in the automotive industry. The metal sheets they produce are widely used in vehicle chassis, panels, mainframes, components, frames, and other components. The automotive industry relies on coil cut to length lines to ensure consistent, high-quality sheet metal produced to stringent standards.

1. Coil cut to length machine for automobile chassis

The basic framework of the car is the chassis, and the sheet metal offered by the coil cut to length line is absolutely essential in its construction. The materials used have great strength and durability because the chassis has to resist the weight of the car and several exterior forces.

2. Coil cut to length machine for automobile panels

The exterior design of a vehicle is closely linked to the quality of its panels. Coil cut to length lines can produce panels with precise shapes and dimensions, ensuring consistency in both appearance and function.

3. Coil cut to length machine for automobile parts

Many automotive parts, such as hoods, doors, and window frames, require high-precision sheet metal. Coil cut to length lines can provide the necessary precision and strength when processing these parts.

4. Coil cut to length machine for vehicle frame

Supporting the whole vehicle structure, the vehicle frame is an essential component, the supplies provided by the coil cut to length line must meet high quality standards in its manufacture. Automakers can improve vehicle safety and longevity by using high-quality sheet metal.

|

|

|

When choosing a coil cut to length line, there are several key factors to consider:

Material Compatibility: Ensure the selected coil cut to length machine can handle the required metal type and thickness to meet production needs.

Production Speed: Select the appropriate coil cut to length line based on production needs to ensure production efficiency.

Sheet Length Accuracy: Verify that the coil cut to length machine can achieve the required length accuracy to ensure product consistency.

Maintenance Ease: Selecting a coil cut to length line with low maintenance requirements can reduce downtime and improve production efficiency.

To satisfy demands across many sectors, KINGREAL STEEL SLITTER focuses on producing premium coil cut to length machines. To guarantee consistently accurate results, increase coil cut to length machine lifespan, and resist large-scale manufacturing, KINGREAL STEEL SLITTER coil cutting to length lines include strong parts.

1. High-Quality coil cut to length machine

KINGREAL STEEL SLITTER coil cut to length lines undergo rigorous quality testing to ensure that each piece of equipment meets international standards. KINGREAL STEEL SLITTER coil cut to length machine not only excel in performance but are also widely recognized by KINGREAL STEEL SLITTER customers for their durability and reliability.

2. Comprehensive after-sales service for coil cut to length line

KINGREAL STEEL SLITTER experienced team provides comprehensive after-sales support, from installation training to maintenance and troubleshooting. KINGREAL STEEL SLITTER goal is to help customers optimize their production processes and ensure efficient coil cut to length machine operation.

3. Focus on customer satisfaction

KINGREAL STEEL SLITTER always prioritizes customer satisfaction. Through continuous improvement and innovation, KINGREAL STEEL SLITTER ensure that our coil cut to length lines can meet KINGREAL STEEL SLITTER customers' ever-changing needs. Whether you are a small business or a large manufacturer, KINGREAL STEEL SLITTER is committed to providing the best solutions.

|

|