Simple coil slitting lines are metal coil processing equipment used to cut metal coils into narrow strips of specific widths. These narrow strips, after secondary processing, are widely used in industries such as automotive, infrastructure, home appliances, and HVAC systems. As a professional simple coil slitting machine manufacturer, KINGREAL STEEL SLITTER is committed to providing customers with suitable simple coil slitting lines to produce narrow strips that meet the needs of various industries. This article will focus on simple coil slitting machines and their working principles in the metal coil slitting process to provide a deeper understanding of simple coil slitting lines.

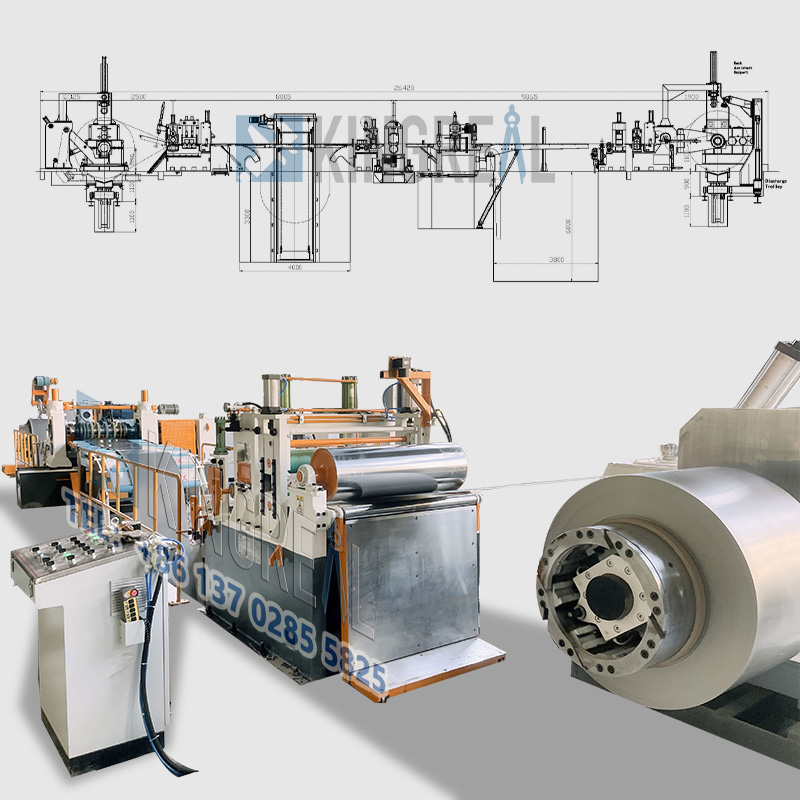

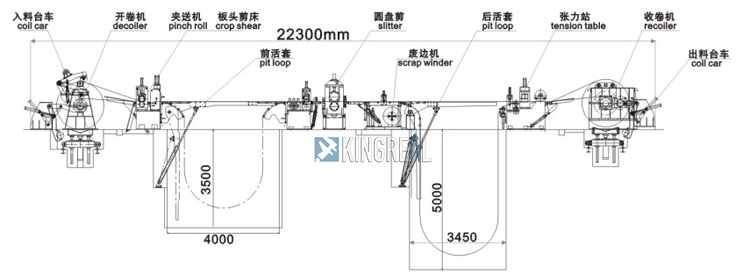

Simple coil slitting lines are highly efficient equipment for slitting metal coils into narrow strips. They primarily consist of a decoiler, a slitter, a waste collection device, and a recoiler. Compared to standard coil slitting machines, these simple coil slitting lines have a smaller footprint and can handle thinner metal coils, while still providing excellent slitting performance, making them ideal for smaller production operations.

1) Decoiler for simple coil slitting machine: It is responsible for unwinding the metal coil for subsequent slitting.

2) Slitter for simple coil slitting line: It is the core component of the simple coil slitting machine, using blades to longitudinally cut the coil into multiple narrow strips.

3) Waste collection device for simple coil slitting line: It collects waste generated during the cutting process, maintaining a clean production environment.

4) Recoiler for simple coil slitting machine: For future packaging and transportation, it rewinds the slit narrow strips.

Designed not only for practicality but also for ease of use, the simple coil slitting machine makes it simple for even small-scale producers to Begin and rapidly reach production.

The simple coil slitting machine's process can be broken into three primary stages: starting with a large, unprocessed coil, slicing it into thin strips utilizing The longitudinal slitting method, and finally recoiling on the recoiler. The specific method is as follows:

1. Uncoiling

The employee initially feeds the coil onto the decoiler's spool beginning simple coil slitting line activity. The decoiler guarantees flawless processing by unraveling the primary coil. Ready for slicing, the unwind metal coil is then steadily moved toward the slitting head.

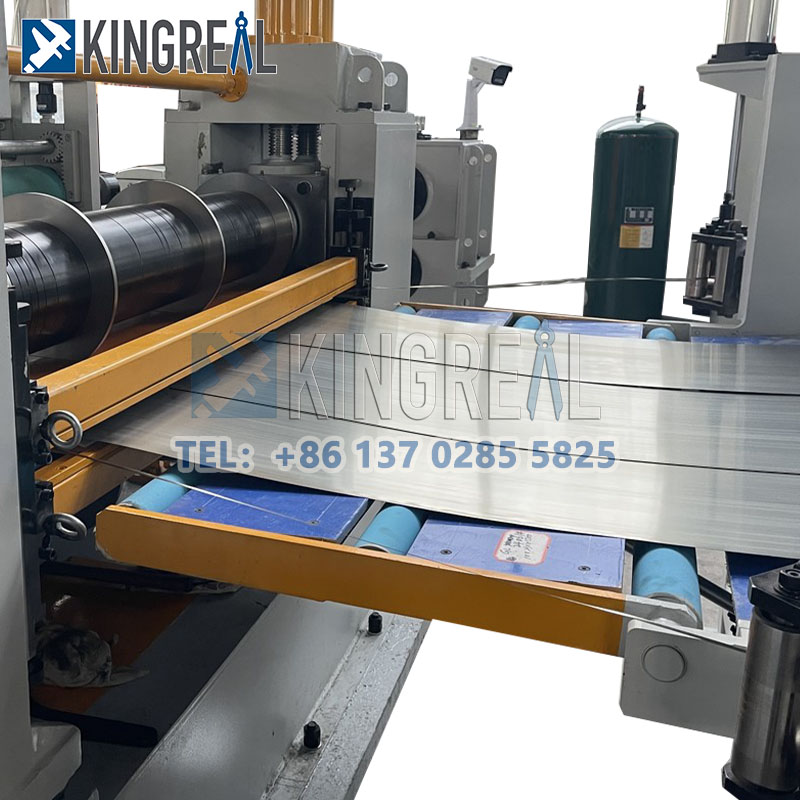

2. Slitting

In the simple coil slitting machine, high-precision rotating blades slit the steel into multiple strips of uniform width. This process requires extremely high blade precision to ensure that each strip is of uniform width, meeting customer specifications. The blades of simple coil slitting lines are typically designed with highly wear-resistant materials, ensuring efficient and stable cutting over extended use.

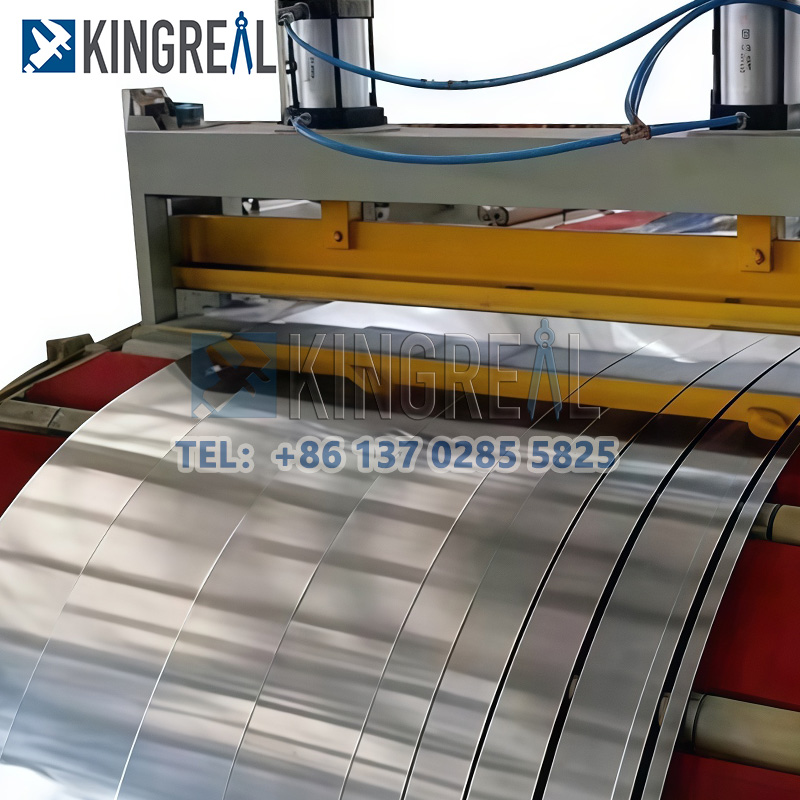

3. Rewinding

The strips pass through a circular groove following slitting to guarantee stress-free rewind of the cut material without warping. For later inspection, packaging, and shipping, the recoiler then systematically coils the strips. In this way, the simple coil slitting line produces an effective cutting and rewinding process, therefore increasing productivity efficiency.

4. Quality Inspection

Following the simple coil slitting line's completion of manufacture, the operator examines the strips to guarantee that their thickness and edge condition meet standards. A major measure in guaranteeing product quality is quality inspection. KINGREAL STEEL SLITTER advises consumers to arm themselves with the needed inspection tools to raise efficiency and accuracy.

5. Packaging and Delivery

The strips are bundled and packed following the customer's particular needs after passing quality check. This is also a very important stage. Good packing helps to guarantee the safe delivery of the goods to consumers and greatly lowers damage risk during shipping.

High-quality simple coil slitting line is what KINGREAL STEEL SLITTER strives to give its customers. These simple coil slitting lines allow effective processing of many different metal coils and slitting of high-quality strips thanks to sophisticated software, tooling, and hardware technology. KINGREAL STEEL SLITTER simple coil slitting machine not only offers high performance, but also optimizes production processes through precise control systems, helping customers improve production efficiency and reduce production costs.

1. Regular maintenance and support for simple coil slitting line

To ensure the long-term stable operation of the simple coil slitting machines, KINGREAL STEEL SLITTER provides regular equipment inspections and maintenance services. KINGREAL STEEL SLITTER professional technical team can perform comprehensive maintenance and calibration to ensure that the simple coil slitting line is always in optimal condition, reduce scrap, and improve production efficiency. KINGREAL STEEL SLITTER also provides a spare parts replacement service, allowing customers to quickly obtain the necessary parts in the event of equipment failure, thereby reducing production downtime.

2. Wide range of applications for simple coil slitting machine

The widespread use of simple coil slitting lines has made them indispensable equipment in many industries. The following are the main areas where KINGREAL STEEL SLITTER simple coil slitting machines are commonly used:

Simple coil slitting line in automotive manufacturing: The narrow strips produced by simple coil slitting machines are used in the manufacture of key components such as automobile bodies and chassis.

Simple coil slitting line in infrastructure: In construction and infrastructure projects, the metal materials produced by simple coil slitting machines are widely used in the production of structural parts.

Simple coil slitting line in home appliance industry: Many home appliances utilize narrow strips processed by simple coil slitting machines for their metal casings and internal components.

Simple coil slitting line in HVAC systems: Simple coil slitting machines can provide metal materials for HVAC equipment, ensuring their performance and durability.

|

|

|

As an efficient metal coil slitting machine, simple coil slitting lines are popular among many small-scale manufacturers for their small footprint, simple operation, and adaptability. Through rational design and advanced technology, KINGREAL STEEL SLITTER simple coil slitting machines can meet the metal strip needs of various industries.

In the future, KINGREAL STEEL SLITTER will continue to be committed to technological innovation and service improvement, providing customers with better quality simple coil slitting lines and professional after-sales service, helping customers to remain invincible in the highly competitive market. For more information about KINGREAL STEEL SLITTER simple coil slitting machines and services, please feel free to contact KINGREAL STEEL SLITTER.