Simple Coil Slitting Machine is used for slitting the sheet metals from wider coil to smaller width coil in vertically section. Simple Coil Slitting Machine work as decoiling the sheets and after metal slitting operation and then recoiling the slitted sheet metal. As Simple Coil Slitting Machine supplier, KINGREAL STEEL SLITTER provides the optimum option as Simple Coil Slitting Machine manufacturer according to our customer’s requested parameters.

Video About Simple Coil Slitting Machine

Video About Simple Coil Slitting Machine

Description Of Simple Coil Slitting Machine

Description Of Simple Coil Slitting Machine

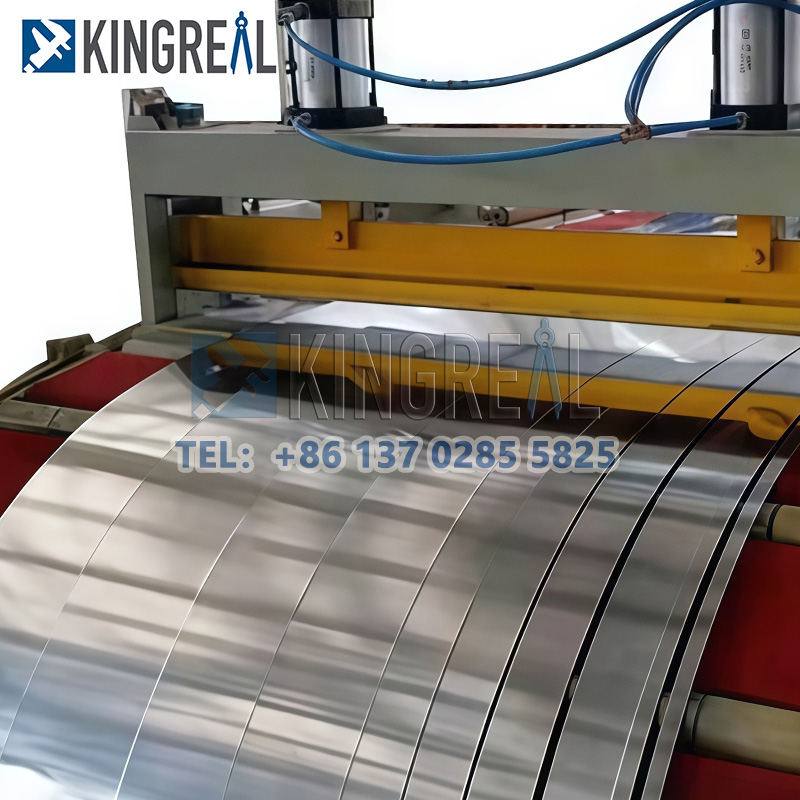

The KINGREAL STEEL SLITTER can provide the simple coil slitting machine for customers with lower budget. The simple slitting machine is mainly used for cutting wide coils into specific narrower coil strips required by customers, and finally rewind the production line.

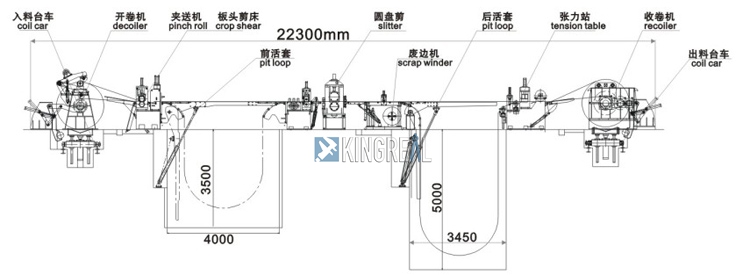

KINGREAL STEEL SLITTER can supply simple slitting machines with any characteristics and cost-effectiveness according to customer requirements. Generally speaking, in order to be able to accurately cut wider coils, the scale of the simple slitting machine line is relatively large. The corresponding venue and cost will be expensive after all.

The simple slitting machine is suitable for a variety of materials including carbon steel, stainless steel, and galvanized steel. It can cut narrow strips with high precision and no burrs. And the simple slitting line has a long service life and a high degree of automation, making it widely used in the metalworking industry.

However, in order to meet customers with low requirements for accuracy and coil width, KINGREAL STEEL SLITTER will also provide a simple version of the metal slitting machine, called Simple Coil Slitting Machine. It can try to simplify the equipment requirements on the premise that the simple slitting line can meet the needs of customers.

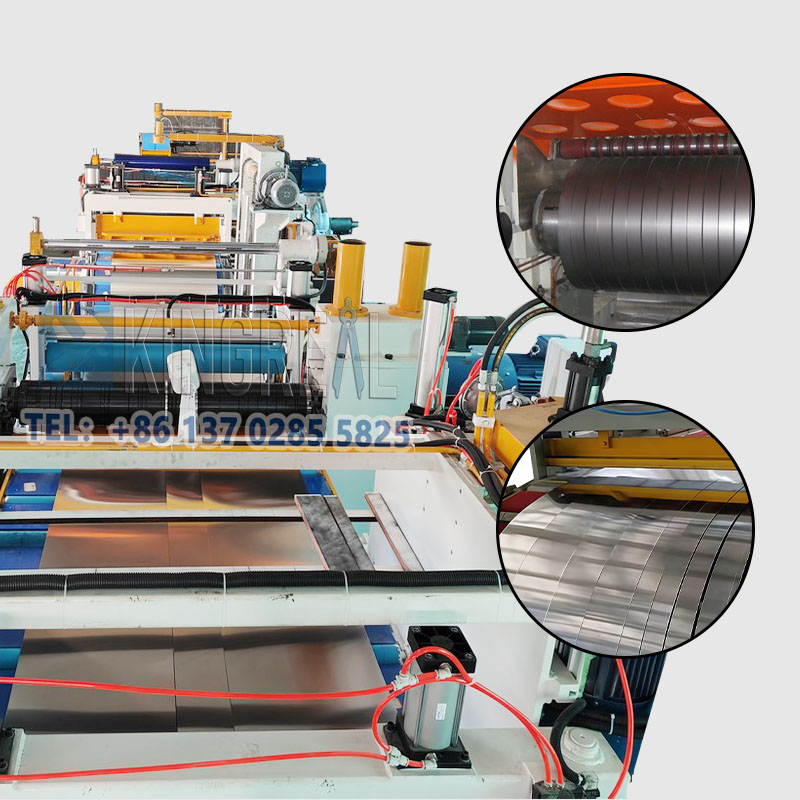

KINGREAL STEEL SLITTER simple coil slitting machine mainly includes: hydraulic decoiler, slitting machine, conveyor, hydraulic winder. This simple slitting machine will complete the process of slitting and cutting the coil into the required size, and then rolling it into the specified profile, and the coiler will wind up the scrap steel at the same time.

Main components details of simple coil slitting machine

Main components details of simple coil slitting machine

● High processing precision: able to meet the requirements of different board shape convexity, with board shape closed-loop control system to ensure the board shape straightness.

● Strong adaptability: capable of handling strips of different thicknesses (0.1-6.0mm) and widths (200-2100mm), applicable to a wide range of metal materials, such as copper strip, stainless steel, cold plate, silicon steel, tinplate,etc.

● Various equipment configurations: according to the coil weight, product surface requirements and other factors, the equipment configuration and cost will have a big difference to meet different production needs.

The simple slitting machine is composed of side guide device to realize positioning bar and stop jumping bar, bottom frame, knife pivot and movable bracket. Slitting high-quality strip steel is an important part, and different sizes can be adjusted according to the blade.

Among them, the cutter shaft is made of Cr-Mo steel, which is precisely manufactured after repeated heat treatment, which can ensure the high precision of the cutting material to the greatest extent.

▶Slitting scrap winder for simple slitting machine

To prevent scrap loss during the coil slitting process, KINGREAL STEEL SLITTER also include scrap winders at the two corners of simple slitting lines. This is standard equipment for simple slitting machines, as scrap at the corners is generally normal. This is common on simple slitting lines due to variations in the matching of coil width and metal slitting width.

▶Separating and tensioning unit for simple slitting machine

To achieve optimal coiling results after slitting metal sheets, the performance of the separating and tensioning units on the simple slitting line is crucial. Tensioning and separating operations significantly impact the performance of the metal slitting machine's coiling unit. Drawing on our extensive experience, KINGREAL STEEL SLITTER design simple slitting machines that deliver flawless results.

The overall steel plate cantilever structure design adopts the hydraulic expansion and contraction model design. Hydraulic arm design, equipped with spacers to ensure uniform winding quality.

In addition, the front and rear ends of the simple slitting machine are equipped with roller devices to reduce the surface damage of materials. At the same time, it is equipped with a removable control panel for easy operation.

Advantage Of Simple Coil Slitting Machine

Advantage Of Simple Coil Slitting Machine

|

1. Low budget for coil slitting linePurchase a simple slitting line that can complete the slitting process at the lowest price, reducing the production cost of the manufacturer. At the same time, the area of the installation site will be greatly reduced, reducing the cost of the site.

2. Easy to operate the simple version of the slitting machine may reduce the equipment on the production line and reduce the complexity of the simple slitting line.

3. Many materials can be divided into strips the simple coil slitting machine can slitting different materials, such as stainless steel, copper strip, steel plate, hot-rolled steel, etc., can be simply slitting.

|

|

Loading coils → decoiling → pinching and shearing→ looping→ guiding → slitting → rewinding scraps → looping → tension → recoiling → unloading baby coils → packing

Technical Parameter Of Simple Coil Slitting Machine

Technical Parameter Of Simple Coil Slitting Machine

|

Coil thickness (mm) |

0.4-0.6 |

|

Maximum speed (m/min) |

20 |

|

Number of slitting machines |

Tailored |

|

Roller stand |

18 |

|

Main power (Kw) |

7.5 |

|

Spindle (mm) |

Ø70 |

|

Tool material |

Cr12 |

|

Cutting accuracy |

10±2mm |

|

Hydraulic station power (Kw) |

5.5 |

|

Control system |

Programmable logic controller |

FAQ

FAQ

Coil processing is the transformation of steel coils into various shapes and sizes.

Common coil processing techniques include cut-to-length, slitting, shape standardization, stretching/straightening, and edge sealing.

Different metal slitting lines will achieve different results and end products, so it is important to know what process you want to accomplish when selecting a metal slitting line.

This page is a metal slitting line for the steel coil category.

With more than 15 years experience in manufacturing the metal slitting machines and KINGREAL STEEL SLITTER is a manufacturer.

So KINGREAL STEEL SLITTER can provide the strong and powerful service before and after sales.

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct to Foshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

KINGREAL STEEL SLITTER will pick you up at the station or airport.