As a professional manufacturer, KINGREAL STEEL SLITTER has more than 20 years of experience in the field of slitting machines. KINGREAL STEEL SLITTER can provide the galvanized steel slitting machine, which is design for precise slitting and rewinding of rolls to specified widths. KINGREAL STEEL SLITTER can ensure the high quality of our galvanized steel slitting machines and is recognized by customers from all over the world. welcome to contact us!

Video About Galvanized Steel Slitting Machine

Video About Galvanized Steel Slitting Machine

Description Of Galvanized Steel Slitting Machine

Description Of Galvanized Steel Slitting Machine

KINGREAL STEEL SLITTER is the most professional galvanized slitting machine manufacturer in China, and can provide the high precision galvanized steel slitting machine to customers from all over the world.

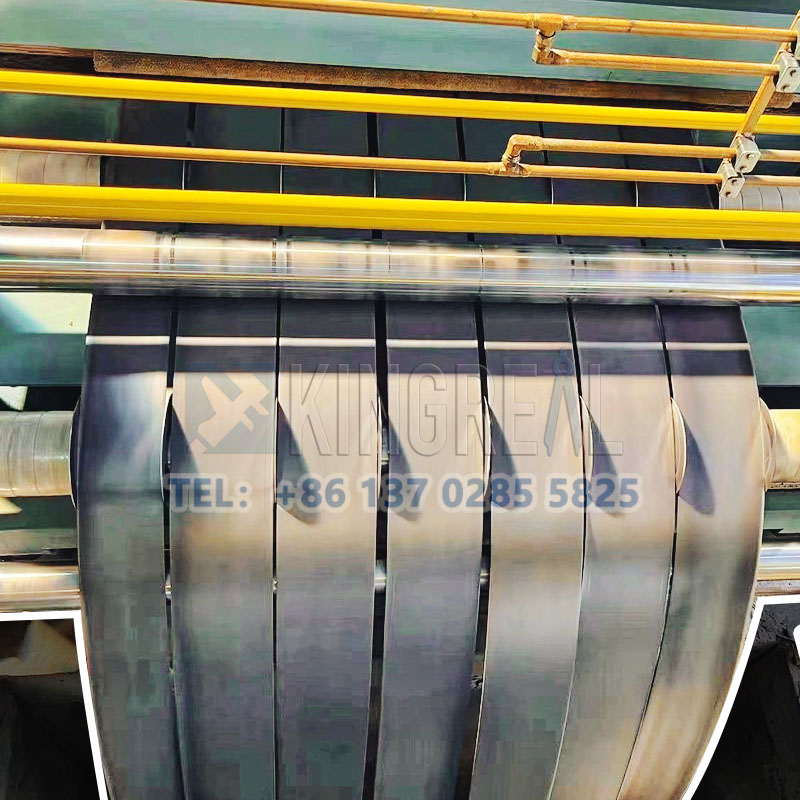

The operating principle of a galvanized steel slitting machine is simple yet efficient. The material to be cut is fed into the galvanized steel slitting line and passed over a set of sharp, circular blades. These blades slit the material quickly and precisely, producing multiple narrow strips in just seconds. Different galvanized steel slitting machines even offer the option of slitting at various angles.

The galvanized steel slitting machine is used to slit galvanized steel coil into different widths and slit as well as smaller strips are rewind at the end of galvanized steel slitting machine according to the production requirements of the user.

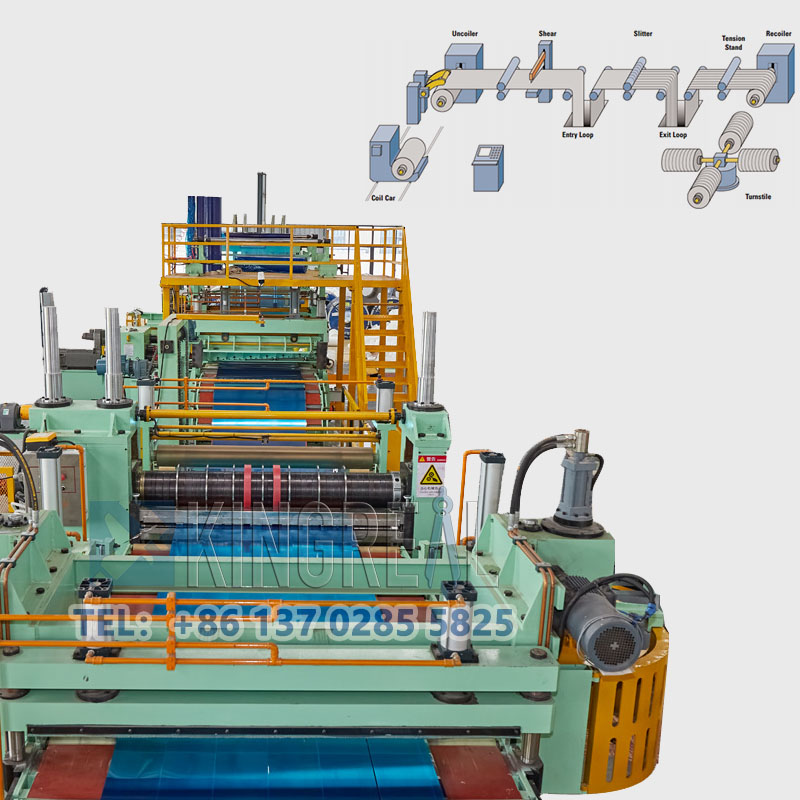

The galvanized steel slitting machine mainly consists of decoiler, leveling,slitting machine, trimming recoiler, separating unit, tensioner and rewinding. In addition to the galvanized steel slitting machine, KINGREAL STEEL SLITTER also can provide other metal slitting machine as different needs of customers, such as

√ 220m/min high speed metal slitting machine

√Belt tension coil slitting line

√High precision coil steel slitting machine

√Full auto coil slitting machine

Working Process Of Galvanized Steel Slitting Machine

Working Process Of Galvanized Steel Slitting Machine

Trolley for loading coil -- Hydraulic decoiler -- Tension station -- Straightener -- Loop bridge -- Slitting machine -- Coil guide -- Pit loop -- Seperatation -- Rewind

Main components details of galvanized steel slitting machine

Main components details of galvanized steel slitting machine

This galvanized steel slitting line uncoiling unit adopts hydraulic collapsible roller, no harm to the bottom layer of material. It can be stretch uncoiling or manual unloading, effectively prevent the material from deflection and scratching.

For large-size coils, KINGREAL STEEL SLITTER designed an uncoiling trolley to realize automatic winding work, saving manpower and increasing the speed of winding.

1. The slitting head mandrel is fixed in the eccentric sleeve. If the blade is just polished, the slitting angle remains the same.

2. The galvanized steel slitting line has two slitting heads. While one is running online, the other can be set up for equipment, which can greatly eliminate production downtime.

3. Hydraulic lock nut is used for higher accuracy of blade positioning.

1. The galvanized steel slitting line can be equipped with a seamless hydraulic retractable winder, which does not damage the material substrate.

2. The clamping device has stress-reducing characteristics. For different thickness of the sheet, the roundness of the reel remains the same.

3. Coiling is firm, dense and neat.

Feature Of Galvanized Steel Slitting Machine

Feature Of Galvanized Steel Slitting Machine

1.Adopt our new patented technology taper tension anti-scratch tension mechanism control system, which solves the problem of tension scratch and winding characteristics.

2.Adopting the newly developed horizontal drive winding mechanism by our technical team, which solves the gear lubrication problem of winding mechanism.

3.This galvanized steel slitting line is controlled by PLC, featuring high degree of automation, high shearing precision, good slitting quality and wide range of applications.

KINGREAL STEEL SLITTER Galvanized Steel Slitting Machine Specification

KINGREAL STEEL SLITTER Galvanized Steel Slitting Machine Specification

|

Material |

Galvanized steel (other can be) |

|

Coil Thickness |

0.5-3mm |

|

Coil With |

500-1600mm |

|

Coil I.D |

508 mm |

|

Coil O.D |

1600mm(Max) |

|

Coil Weight |

20 T |

|

Machine Power |

380V/50Hz/3Ph |

|

Slitting Speed |

0-220m/min |

|

Capacity |

210 Kw |

|

Machine Color |

Customized |

KINGREAL STEEL SLITTER provides customized galvanized steel slitting line manufacturing solutions based on our customers' specific needs. Therefore, each galvanized steel slitting machine we sell has different specifications and performance.

For example, KINGREAL STEEL SLITTER categorizes our galvanized steel slitting lines into three types based on the thickness of the metal coils we process: light gauge slitting machines, medium gauge slitting machines, and heavy gauge slitting machines.

Light gauge slitting machine: can process sheet metal thicknesses of 0.2-3mm.

Medium gauge slitting machine: can process sheet metal thicknesses of 3-6mm.

Heavy gauge slitting machine: can process sheet metal thicknesses of 6-16mm.

|

|

|

FAQ

FAQ

KINGREAL STEEL SLITTER is a professional manufacturer and supplier. We offer full solutions in coil processing and machine tool building, which including high speed coil slitting line, copper slitting machine, 200m/min coil slitting machine, simple slitting machine, cut to length line machine, fly shearing for cut to length machine, metal cut tolength machine. KINGREALSTEEL SLITTER have a professional team and rich project experience, can provide you with the best service, welcome to contact us.

Our factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct toFoshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

We will pick you up at the station or airport.

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?