KINGREAL STEEL SLITTER Heavy Gauge Precision Slitting Machines are designed for processing thicker and heavier metal coils, typically ranging from 6mm to 16mm in thickness, depending on the material. Heavy Gauge Precision Slitting Machines are robust and engineered to handle heavy gauge coils with high strength and weight while maintaining precision and efficiency.

Video About Heavy Gauge Precision Slitting Machine

Video About Heavy Gauge Precision Slitting Machine

Description Of Heavy Gauge Precision Slitting Machine

Description Of Heavy Gauge Precision Slitting Machine

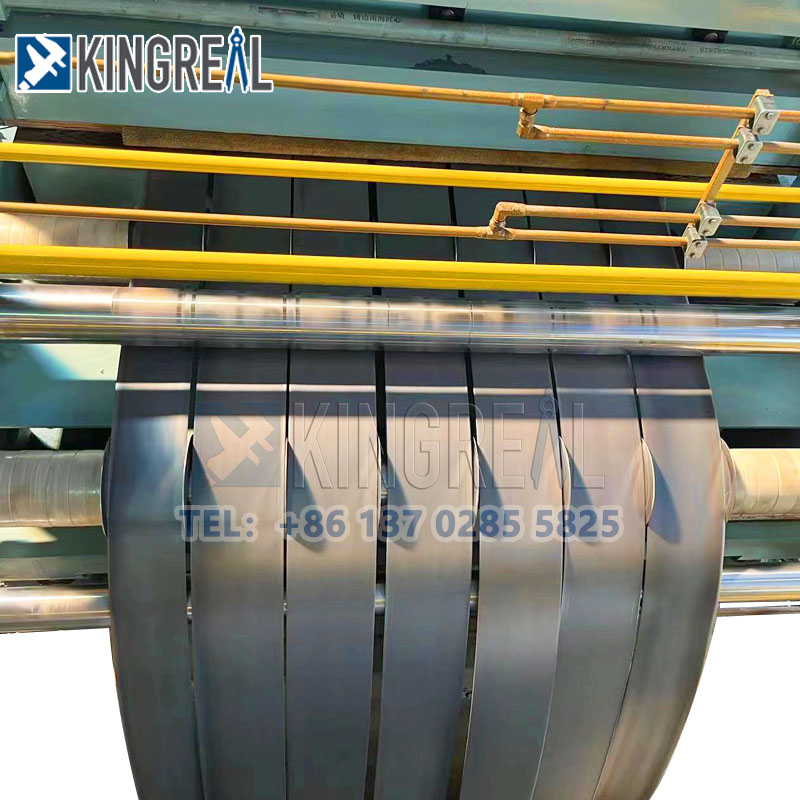

KINGREAL STEEL SLITTER heavy gauge precision slitting machine are specifically designed for slitting high-strength, thick-gauge materials.

This heavy gauge precision slitting line is capable of processing different materials such as cold rolled steel coils, hot rolled carbon steel coils, stainless steel coils, copper, brass, aluminum and such as pre-painted steel coils.You can buy the high quality heavy gauge precision slitting machine from KINGREAL STEEL SLITTER.

In order to be able to slit more precisely according to the high-standard characteristics of the material, KINGREAL STEEL SLITTER has made a specific design for the components on the heavy gauge precision slitting machine.

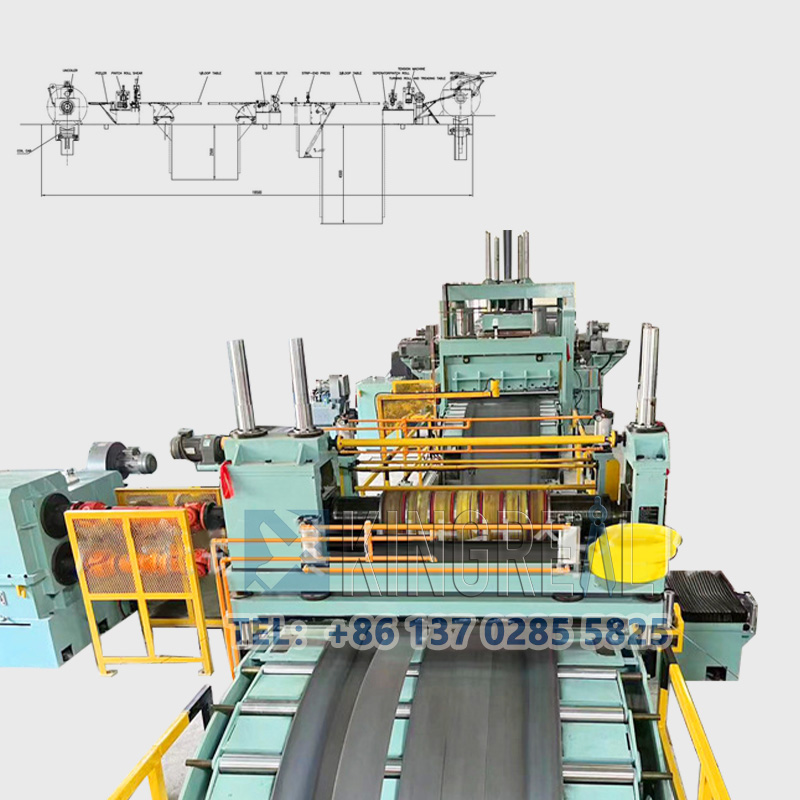

The heavy gauge precision slitting machine can slit coil material up to 16mm thick and 2500mm wide, which is consists of trolley car, hydraulic decoiler, guiding device, pinch roller, heavy gauge slitting machine, dual slitter head, loop, tension and rewind.

Advantage Of Heavy Gauge Precision Slitting Machine

Advantage Of Heavy Gauge Precision Slitting Machine

● High quality heavy gauge precision slitting lines with minimal burrs on the strip

● KINGREAL STEEL SLITTER provides the uncoiling trolley, which adopts hydraulic uncoiling. To achieve the effect of automatic roll-up.

● -KINGREAL STEEL SLITTER design offers 2 complete slitting heads for quick tool changeover.

● KINGREAL STEEL SLITTER heavy gauge precision slitting line is a highly automated production that can improve economic efficiency.

● Intelligent operating system, multilingual operating instructions, easy to operate and maintain.

● Heavy duty slitting machines are available in different capacities and standards according to customer needs.

● Widely recognized by customers.

Working Procedure Of Heavy Gauge Precision Slitting Machine

Working Procedure Of Heavy Gauge Precision Slitting Machine

Hydraulic Coil Car -- Hydraulic Decoiler -- Pinch Leveler Shear -- Loop Bridge -- Heavy Gauge Slitting Machine -- Double Slitter -- Rear loop Pit & Bridge -- Tension-- Recoiler

Parameter Of Heavy Gauge Precision Slitting Machine

Parameter Of Heavy Gauge Precision Slitting Machine

|

Coil Material |

cr, hr, stainless steel, gi, aluminum, copper, silicon, steel |

|

Coil Thickness |

6.0~16.0mm |

|

Coil Weight |

≤30T(35T) |

|

Coil I.D |

φ508,φ610,φ760mm |

|

Coil O.D |

≤φ2200mm |

|

Slitting Line Speed |

0~60m/min |

|

Strip Width |

Strip Width |

|

Number of Strip |

5~20 |

|

Slitting Accuracy |

±1.0mm |

|

Electrical Control System |

PLC Automatic control |

The specifications of different products require the design of different heavy gauge precision slitting machine parameters, the above participation is only for reference. In order to help customers achieve their own production capacity goals, KINGREAL STEEL SLITTER heavy gauge precision slitting lines will provide a variety of options, and slitters with different speeds and different needs are easy to operate.

Application Of Heavy Gauge Precision Slitting Line

Application Of Heavy Gauge Precision Slitting Line

- Automotive Part

- Electrical

- Tags

- Fin Tube Application

- Other Metal Material Manufacturer

KINGREAL STEEL SLITTER is not only committed to providing customers with high-quality heavy gauge precision slitting machines, but also attaches great importance to after-sales service, ensuring that customers receive comprehensive support throughout their use. KINGREAL STEEL SLITTER after-sales services include heavy gauge precision slitting machine installation, operator training, maintenance services, and spare parts supply. For heavy gauge precision slitting machine installation, KINGREAL STEEL SLITTER professional engineers will provide on-site installation services tailored to customer needs, ensuring that each heavy gauge precision slitting machine can be put into production smoothly.

KINGREAL STEEL SLITTER also offers comprehensive heavy gauge precision slitting machine operation training. To help customers quickly master the use of the heavy gauge precision slitting machine, KINGREAL STEEL SLITTER arranges professional training courses covering basic operation, maintenance, and troubleshooting common problems. To date, KINGREAL STEEL SLITTER engineers have traveled to countries including the United States, Brazil, Qatar, and Mexico to provide face-to-face after-sales service. In addition to on-site training, KINGREAL STEEL SLITTER also provides heavy gauge precision slitting machine operation training to customers through online meetings. This flexible training method allows customers to conveniently participate in training and quickly master operating skills, regardless of their location.

FAQ

FAQ

KINGREAL STEEL SLITTER always test and adjust our machines before shipment; if needed, KINGREAL STEEL SLITTER also send samples of our machine production to our customers for confirmation.

KINGREAL STEEL SLITGTER offer full solutions in coil processing and machine tool building, which including high speed coil slitting line, copper slitting machine, simple coil slitting machine, cut to length line machine, fly shearing cut to length machine.

KINGREAL STEEL SLITTER have a professional team and rich project experience, can provide you with the best service, welcome to contact us.

1.How To Operate The Coil Slitting Line Safely?

2. How to Repair Aluminum Coil Slitting Machine?

3. How To Maintain The Coil Slitting Machine

4. What Is The Role Of metal slitting machine tension?

5. What Is The Speed of Coil Slitting Line?