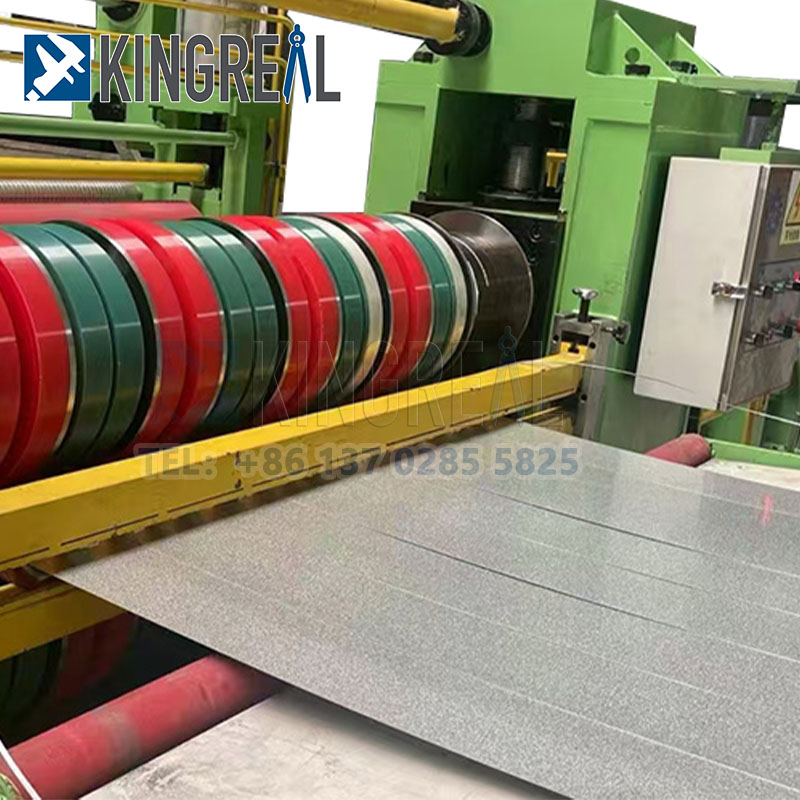

KINGREAL STEEL SLITTER Steel Strip Slitting Machine is an advanced system designed to uncoil wide metal coils, slit them into narrower strips with precise widths, and then rewind them into separate coils. These Steel Strip Slitting Machines are suitable for a wide range of materials, including stainless steel, galvanized steel (GI), carbon steel, aluminum, copper, hot rolled steel, and cold rolled steel. The system is composed of key components such as the uncoiler, press and pinch, slitter, edge scrap winder, tension control unit, and recoiler—all operating fully automatically with high accuracy and efficiency.

Video About Steel Strip Slitting Machine

Video About Steel Strip Slitting Machine

Steel Slitting Machine Description

Steel Slitting Machine Description

KINGREAL STEEL SLITTER high-precision steel slitting machine is mainly used for slitting production of stainless steel strip/roll, carbon steel strip, copper strip, silicon, CI, PPGI,etc. The steel slitting machine is produced by loading trolley, hydraulic decoiler, pinch roller, slitting machine, loop bridge,tension, rewind and electrical system, etc.

Steel slitting machines are used to slit sheet metal from wider coils into narrower coils. Steel slitting lines unwind the sheet metal, perform the slitting operation, and then recoil the slitted sheet metal.

KINGREAL STEEL SLITTER adopts the electric and pneumatic control to achieve the high production efficiency of steel slitting line. As one of the most profession steel slitting machine manufacturer in China, KINGREAL STEEL SLITTER can provide various steel slitting line according to the different needs of customers, for example, Simple Coil Slitting Machine, Galvanized Steel Slitting Machine, Narrow Strip Coil Slitting Machine, 1600MM Coil Slitting Machine, etc.

Advantage of the Steel Slitting Machine

Advantage of the Steel Slitting Machine

Considering the high surface requirements of the materials processed by the whole set of steel slitting machine, KINGREAL STEEL SLITTER specially designed various roller conveyors.

The components, size, tools, horsepower and tension in the machine are appropriate for the material being cut. After surface treatment, the steel slitting machine will not cause indentation, scratches, scratches, folding and undercut of the sheet during the production process.

KINGREAL STEEL SLITTER steel slitting machine features a robust and durable structure. High-precision components are used in the hydraulic components, and PLC program controllers and touch screens control all line functions, resulting in highly automated production.

Appropriate, high-quality slitting tools and accessories are used to meet the specific production conditions and specifications of each customer, ensuring consistent quality of the finished slitting products. The steel slitting line operates reliably and safely, and regular maintenance extends the life of the steel slitting machine and its slitting tool accessories.

KINGREAL STEEL SLITTER continuously refines its slitting processing technology to provide customers with high-performance and high-quality steel slitting lines.

In order to help customers achieve high production efficiency, KINGREAL STEEL SLITTER has made special designs on decoiler, slitting machine and other components.

- Provide loading trolley for unwinding, improve the efficiency of winding.

- Provide double knife seats for slitting, so that the specifications of the knife seats can be adjusted in time during the operation of the steel slitting machine. Achieve the purpose of saving time and improving production efficiency.

Feature Of Steel Slitting Machine

Feature Of Steel Slitting Machine

1) High-speed cantilever decoiler mechanism, using the ground to uncoil, reducing the pain of digging pits.

2) Adopting a spacer type round shear, on which a locking type blade can also be installed, making it a dual-purpose round shear.

3)Adopt the airbag type pressing to ensure to keep the balanced tension in different thickness.

4)Adopt our new patented technology taper tension anti-scratch tension mechanism control system, which solves the problem of tension scratch and winding characteristics.

5)This steel slitting machine is controlled by PLC, featuring high degree of automation, high shearing precision, good slitting quality and wide range of applications.

Main Procedure Of Steel Slitting Machine

Main Procedure Of Steel Slitting Machine

Hydraulic Decoiler -- Pinch Roller -- Loop Bridge For Pit -- Side Guide Pinch Roller -- Slitting machine -- Loop Pit & Bridge -- Edge Coil Winder -- Tension Station --Separator -- Hydraulic Rewinder

Specification Of Steel Slitting Machine

Specification Of Steel Slitting Machine

|

Material |

steel strip/roll, carbon steel strip, copper strip, silicon |

|

Steel Thickness |

0.3-3mm |

|

Steel Width |

500-1600(Max) |

|

Max Steel Weight |

20 T |

|

Slitter Header Material |

6CrW2Si |

|

Slitting Machine Power |

380V/50Hz/3Ph |

|

Slitting Machine Speed |

0-220m/min |

|

Slitter Line Capacity |

210 Kw |

1. Steel Slitting Line in Automotive: Body sheet processing.

2. Steel Slitting Line in Home Appliances: Slitting stainless steel and galvanized sheet for home appliances.

3. Steel Slitting Line in New Energy: Slitting lithium battery tabs.

4. Steel Slitting Line in Packaging: Slitting tinplate for canning.

FAQ

FAQ

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct to Foshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.KINGREAL STEEL SLITTER will pick you up at the station or airport.

KINGREAL STEEL SLITTER always test and adjust our machines before shipment; if needed, we also send samples of KINGREAL STEEL SLITTER steel slitting machine production to our customers for confirmation.

In order to help KINGREAL STEEL SLITTER customers to solve steel slitting machine installation problems, KINGREAL STEEL SLITTER will provide both online and local installation services.

Online installation guide

- Photos and videos of steel slitting machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting