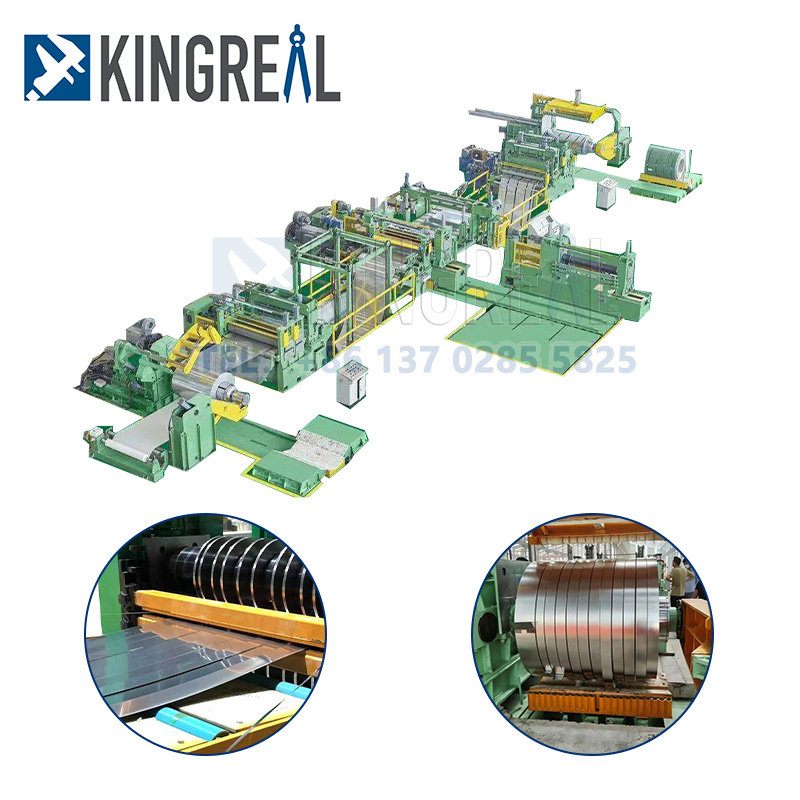

Metal Coil Slitting Machine is a specialized production line designed to cut wide metal coils into narrower strips of precise widths. These strips are then recoiled for easy handling and transportation. The Metal Coil Slitting Machine typically consists of a decoiler, a slitter, and a recoiler, among other auxiliary equipment.

Video about Metal Coil slitting Machine

Video about Metal Coil slitting Machine

Brief Introduction Of Metal Slitting Machine

Brief Introduction Of Metal Slitting Machine

The metal slitting machine is designed for slitting the metal coil to the strip according to the customer needs and then re-coil the slit metal sheets. The KINGREAL STEEL SLITTER metal slitting line is an automatic production line with simple operation and high production efficiency, and can produce up to 40 narrow strips at a time.

The metal slitting machine produce the different width metal coil, which is widely used in metal sheet processing industry such as automobile, agricultural vehicle, container, home appliance, building materials, etc. The raw material characteristics, thickness, width and coil weight of the metal coil are very important for the selection and design of the metal slitting machine, such as the slitting knife seat and the leveling machine. Choosing a suitable metal slitting machine can help customers obtain long-term production benefits.

Metal Coil Slitting Machine Composition Equipment

Metal Coil Slitting Machine Composition Equipment

Process Of Metal Slitting Machine

Process Of Metal Slitting Machine

Loading → Decoiler→ Transfer bridge → Guided slitting → Scrap collection → Transfer bridge → Tension → Reeling → Unloading

KINGREAL STEEL SLITTER Metal Slitting Machine Feature

KINGREAL STEEL SLITTER Metal Slitting Machine Feature

Metal scoil slitting machine coil car loading can store the rolls on storage racks with a crane, and manually tighten the rolls on the uncoiler reel with a loading trolley. High-end metal slitting machines can be equipped with fully automatic centering systems (such as EPC automatic edge alignment), which can achieve precise positioning through sensors and hydraulic feedback, reducing manual intervention

Metal coil slitting machine decoiler device takes hydraulic oil cylinder rotating joint to get the expansion of the coiling drum. The unwinding device of the metal slitting machine drives the reel to rotate through mechanical transmission or hydraulic system, gradually unwinding the metal coil (such as steel coil, aluminum coil, etc.) and maintaining a certain tension to prevent the material from loosening or deformation.

High precision slitting width tolerance and straightness. The blade holder of the metal slitting machine uses a mechanical structure (such as a shaft and a fixed seat) to accurately fix the blade in the set position to ensure that the blade does not deviate or vibrate during cutting, thereby ensuring the consistency of the slitting width.

Vertical type scrap recoiler for more convenient working. The scrap winding device of the metal slitting machine drives the winding roller or wire reel through the motor to automatically wind the scrap (such as metal edge materials, waste wire) into a roll to avoid the scrap scattering and causing safety hazards or environmental pollution.

Hydraulic type with separators in the top, and pushing device for easy unloading.

Details Regarding The Metal Slitting Line

Details Regarding The Metal Slitting Line

|

Machine Name |

Metal Slitting Line |

|

Coil Material |

Metal(other can be customer) |

|

Max Coil Thickness |

3.0mm |

|

Max Coil Width |

1600mm |

|

Max Coil I.D |

760mm |

|

Max Coil O.D |

2000mm |

|

Strip Width |

Customization |

|

Number Of Coil Strip |

up to 35 |

|

Voltage |

380V |

|

Rated Power |

50KW |

|

Capacity |

50KW |

(1)Metal slitting line in automotive industry

The precision narrow strips produced by metal slitting machines are critical for the production of parts such as structural brackets, fuel system components, and exhaust elements. Tight tolerances and clean edges help improve part reliability and meet stringent safety and performance requirements. Automakers rely on high-quality metal slitting lines to reduce waste, streamline production processes, and ensure consistent product quality.

(2)Metal slitting machine in aerospace industry

In the aerospace manufacturing industry, stringent standards require slit webs with uniform widths and flawless edges. Applications such as turbine blades, heat exchangers, and fuselage components rely on burr-free edges and consistent flatness. This industry demands metal slitting lines with superior control, traceability, and quality assurance.

(3)Metal slitting machine in energy industry

Fuel cell and electrolyzer manufacturers require dimensionally precise slit webs with smooth edges to ensure optimal sealing, welding, and stacking. In these power generation applications, burrs or edge defects can compromise system integrity or shorten product life. This is why they require metal slitting lines that produce superior edge quality and consistent finished products.

What does our factory look like?

What does our factory look like?

Why choose us?

Why choose us?

KINGREAL STEEL SLITTER has over 20 years’ experience in coil slitting machine and cut to length line, has been successfully transport our machine to many countries, such as Russia, India and Saudi Arabia, etc.

As a professional machine supplier, KINGREAL STEEL SLITTER has its own factory in China, providing a one-stop service encompassing design, R&D, manufacturing, delivery, and installation. KINGREAL STEEL SLITTER ensures meticulous attention to detail at every stage, delivering high-quality machines to our clients. The KINGREAL STEEL SLITTER team offers a transparent price list and customizes machine manufacturing solutions based on each client's specific project needs. Contact KINGREAL STEEL SLITTER today for the latest machine quotation!

|

√ Professional design team √ high quality production process √ Rich project experience √ After-sales installation service √ The sincerity of long-term cooperation |

|

How to order?

How to order?

FAQ

FAQ

There are 2 ways: either by plane or by train to Foshan/Guangzhou port. We will be picking you up in plane/train station, then we can go together.

12 months except human error, during which all parts damaged because of quality problem will be changed for free.

Parts that are out of warranty will be provided in factory price.

Within 60-80 days after receiving prepayment. Some machines in stock, can be delivered at any time.

40% deposit is paid before production, the balance paid after inspection confirmation before shipment.

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, Manual book and video is provided to show how to install and operate.