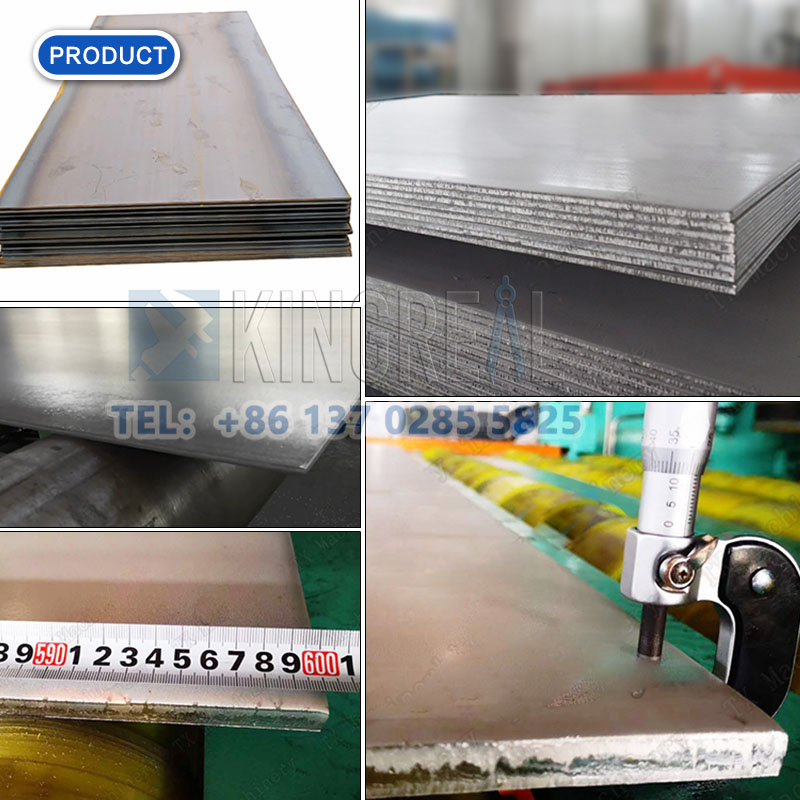

Heavy Gauge Cut To Length Line - 2024 KINGREAL is designed to process heavy metal coils with a thickness of 6-25mm and cut them into precisely sized metal sheets.

Heavy Gauge Cut To Length Line - 2024 KINGREAL STEEL SLITTER can provide both cut to length line, high speed cut to length machine, simple cut to length line and this heavy gauge cut to length machine, which can precision cut-to-length of hot rolled steel, cold rolled steel, stainless steel, silicon steel and other metal coils with automatic stacking device for a fully automated production process.

Due to its high strength, good toughness, easy processing and forming and good weld-ability, thick sheet metal coil is widely used in various industrial fields, to meet the needs of different industries. Heavy Gauge Cut To Length Line demand is increasing, the processing of thick sheet metal coil for the higher requirements of the equipment, from the uncoiling equipment leveling to shear and stacking. The requirements for the load-bearing range are much higher than for other thicknesses of sheet metal.

KINGREAL STEEL SLITTER Heavy Gauge Cut To Length Line is specially designed to process coils with a thickness range of up to 6-20MM by decoiler, straightener, measuring, cut to length machine and stacking.

|

Name |

Detail |

|

Raw material |

Q235 HR |

|

Sheet thickness |

5.0~20.0mm |

|

Sheet width |

900~2000mm |

|

Machine input net width |

2000mm |

|

Outer diameter of coil |

Φ1000~Φ2200mm |

|

Inner diameter of coil |

Φ550~Φ760mm |

|

Maximum coil weight |

30T |

|

Stacking length |

1000~12000mm |

|

Ruling accuracy |

≤±1.5mm/3M |

|

Diagonal accuracy |

≤±1.5mm/3M |

|

Leveling accuracy |

≤±2.0mm/M |

|

Operating speed |

0~25m/min |

|

Total power |

~500KW |

|

Machine center height |

1000mm |

Hydraulic Decoiler-- Frame Hydraulic Pilot Machine--Seven-roll leveling machine--Double-head trimmer -- Scarp Collector -- Eleven-roll leveling machine -- Pneumatic sizing device -- Tailboard feeder -- Hydraulic cutting machine -- Stacking machine

a.Capacity :30T

b.Brake Specifications: 4-DBH205

c.material frame lifting stroke 650mm (lift directly to the reel, can come to material steel liner removed)

d.Adopting double bearing double cone top pressure type mechanism to clamp the steel coil, the movement of the second end of the machine base is driven by hydraulic cylinders and has the function of simultaneous drive centering, the spindle at the second end of the uncoiler is designed with pneumatic disc brake device.

It adopts the structure of two-roller clamping and feeding and five-roller leveling. The motor drives the upper and lower rollers through the reducer and distribution box through the universal connecting shaft, the upper roller adjusting and pressing down for the feeding is executed by the hydraulic cylinder, and the upper roller adjusting and pressing down for the leveling is executed by the electric power. Considering the synchronous operation of the pre-schooling machine and the leveling host, the motor control is controlled by the American PARKER590C series DC control system. The universal connecting shaft adopts the mill industrial universal shaft.

Leveling roller diameter : Φ220mm

Leveling roll spacing : 260mm

Rollers Quantity : 2+5 Rollers

Roller material : GCr15 forged steel with tempered and medium frequency hardened (HRC60)

Main motor power : 132KW DC

Power of motor for adjustment: 2-7.5KW

Main Reducer: JZQ850

Adjustment reducer : 2-BWY4 Swing reduction

a.Function: Preventing the sheet from running out of shape when running, and regulating the sheet into the leveling main machine. It consists of machine base, limit roller, supporting seat slide, guide roller and adjustment device. Vertical guide rollers are provided on both sides of the sheet width direction, and the guide roller frame is fixed on the respective slide, which moves the slide on the guide column in the direction of the sheet width through the motor by means of the wire rod nut payment, so as to adapt to the different sheet widths. The adjustment is motorized.

b.Adjustment range: 900~2000mm

Guide roller material: Gcr15(HRC60)

Adjustment motor: 2~3KW

Adjustment reducer: 2-WPDKS135Worm reducer

Function: The shearing machine mainly accomplishes the tasks of head cutting, tail cutting, side trimming, longitudinal shearing and cut-to-length shearing.

Material adaptability: It is suitable for steel plates of different thickness and materials, such as ordinary carbon steel, high-quality low alloy steel, alloy steel, pipeline steel and stainless steel plate.

Degree of automation: the whole process works automatically, reducing manual operation and improving production efficiency.

Accurate measurement: with high precision measurement to ensure accurate cutting size.

Shear Blade Gap Adjustment: Shear blade side gap can be adjusted to ensure cutting quality.

a.Model: Hydraulic brake

b.Strokes per minute: 8~12 times

c.Blade material: Cr12Mov

d.Motor Power: 55KW

Feeding station:

a.It consists of a frame, a swing roller table, a conveyor roller conveyor and a power unit. Its function is to input the flat plate into the throwing machine.

b.Motor: 7.5KW

c.Reducer: BWY4 Swing reducer

Main feeder:

a.It consists of machine base, plaque, slider, throwing roller and power unit. Throwing material upper roller lifting and lowering for pneumatic implementation. The transmission is mechanical. Its function is to feed the plate into the yarding table.

b.Motor: 7.5KW

c.Reducer: BWY4 Swing reducer

Stacking Table: It consists of steel plates and steel sections welded together. Its function is to stack the calibrated flat plate. Length 12 meters.

Pneumatic stocker: It consists of one set of longitudinal limits leveling device and three sets of transverse limits leveling device. Both the limiting and adjusting mechanisms can be adjusted according to different board widths, and the adjustment is manual. The material rectifying execution is a pneumatic actuator.

|

|

|

1. Full range of customized services, according to the customer's plate production needs to provide heavy gauge cut to length line drawing design, can be configured with the choice.

2. Provide various configurations for heavy gauge cut to length line, such as loading trolley, trimming device, automatic stacking, automatic discharging, etc.; realize fully automatic production.

3. Provide a variety of accessories to ensure the stability and longevity of the heavy gauge cut to length line;

4. engineers local after-sales service guarantee, can guide the installation of heavy gauge cut to length line on site.

5. 24/7 on-line after-sales service, technical answer.

1/ What is the maximum thickness of steel plate your cut to length line machine can cut?

KINGREAL STEEL SLITTER cut to length lines can cut metal materials with thicknesses ranging from 0.2 mm to 25 mm. The specific model recommended will depend on your requirements.

2/How long do cut to length machine blades last?

The lifespan of cut to length machine blades depends on the material being cut and the frequency of use. KINGREAL STEEL SLITTER also offers custom alloy steel blades to extend service life.

3/Which materials are suitable for cut to length lines?

KNGREAL cut to length machines are primarily suitable for steel, stainless steel, carbon steel, aluminum, copper, and other metal materials.

4/What if the cut to length machine breaks down?

KINGREAL STEEL SLITTER cut to length machines are of very reliable quality. If any parts are damaged, KINGREAL STEEL SLITTER will provide you with replacement parts.

5/What types of cut to length machines do you offer?

KINGREAL STEEL SLITTER will provide cut to length machines that match the customer's actual project requirements, including processing material, material thickness, width, length, and cutting method. And KINGREAL STEEL SLITTER can also equip the cut to length machines with special components.