A simply cut to length line is a crucial piece of coil processing equipment, designed to cut raw materials horizontally according to customer needs and prepare them for subsequent forming processes. The material processed by the simple cut to length line is typically used for a single forming process, such as sheet metal stamping, bending, and stretch forming. Simply cut to length lines are widely favored due to their small footprint and suitability for processing thin, lightweight metal materials, making them particularly suitable for small-scale production or for those new to the industry.

This article details the basic configuration of a simple cut to length line, hoping to provide valuable reference.

Simple cut to length lines are specifically designed for processing relatively lightweight metal materials. Their production speeds are slow, and machine frame rigidity is relatively easy to maintain. Furthermore, due to their low installed capacity, simply cut to length lines occupy a relatively small footprint, making them ideal for small-batch production. However, as sheet widths, material thicknesses, and coil weights increase, the increased production speed necessitates a significant increase in safety margins, posing challenges to simplified design.

Furthermore, the feeding and post-cutting stacking systems of simple cut to length lines vary depending on specific needs, resulting in diverse configurations and challenges in standardization. Therefore, understanding the combination of various related equipment is one of the keys to mastering the configuration of a simply cut to length line.

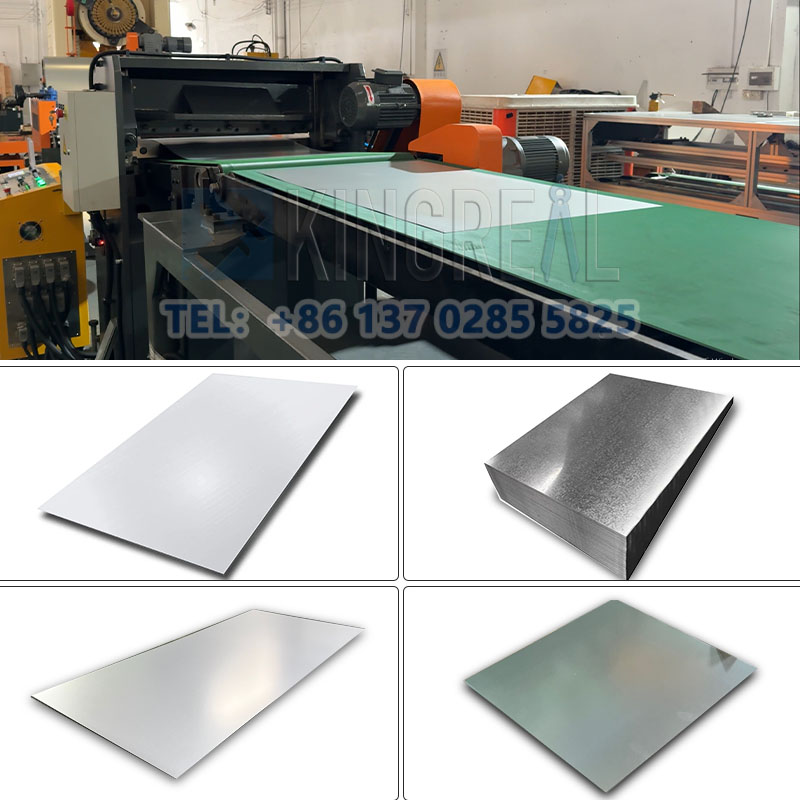

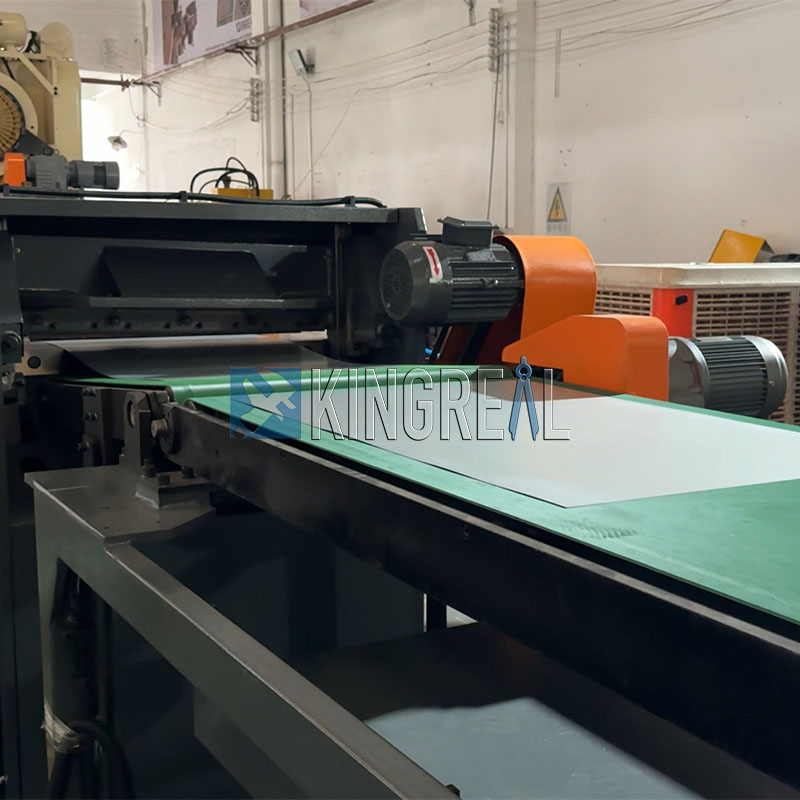

A simple cut to length line primarily consists of independent decoiler, straightener, CNC servo roller feeder, and cut-to-length machine. The entire simply cut to length line's loading, uncoiling, straightening, feeding, and cutting processes are automated. To help you better understand this type of simple cut to length line, a simply cut to length line designed and developed by KINGREAL STEEL SLITTER engineers has been released on YouTube. You can quickly view the content.

|

|

During the initial production of materials, a simply cut to length line is designed to retain the basic functions of the corresponding production line. Especially for simple cut to length lines, different combinations can meet diverse production needs. Therefore, understanding the customer's specific needs is the foundation for developing the optimal machine configuration.

●Material loading and guide system for simply cut to length line

The design of the material loading and guide system of a simple cut to length line also depends on the customer's material characteristics. Generally, the material loading system of a simply cut to length line can be a combination of split-unit equipment or two-in-one equipment (such as GO, ML, CL, TGL, etc.). When selecting the material handling section, factors such as material width, inner and outer diameters, material thickness, material holding method, and load capacity must be considered to ensure proper power configuration and the need for auxiliary support.

For the correction section, the design must select the appropriate correction wheel size and layout based on the material thickness, while also determining the correcting machine power based on production speed. The customer's flatness requirements will also influence the number, layout, and drive method of the correction wheels. As a simple cut to length line manufacturer serving the international market, KINGREAL STEEL SLITTER engineers fully considered the international market's emphasis on safety when designing the center material holder and correction variable speed controller for the simply cut to length line.

The feeding section of the simple cut to length line is selected based entirely on the customer's cut-to-length requirements and sheet material efficiency. Depending on the power source, the feeding section can be configured with AC variable speed control, DC motor control, or servo motor control. For construction cross-cutting applications with poor material quality and large cut-to-length tolerances, a circuit consisting of a correction power supply, a frequency converter, and a length encoder can be used for direct cut-to-length. For thicker and stronger materials with lower production requirements, a combination of a DC motor and a length encoder is also a good option. For materials requiring high speed, high production capacity, and a high degree of automation, a servo-based cut-to-length system is recommended.

●Shearing section for simply cut to length line

The shearing section of a simple cut to length line is primarily categorized into several types, including the simply cut to length line's built-in head shear, mechanical (hydraulic) shears, and pneumatic clutch high-speed shears (or hydraulic high-speed shears). For simple cut to length lines with low production requirements, the head shear can be used directly. For low- to medium-end metal cut to length lines with wide material widths and a wide thickness range, mechanical shears or hydraulic shears are more suitable. For applications with higher shearing requirements and a certain speed requirement, pneumatic clutch high-speed shears or hydraulic high-speed shears should be considered.

●Product collection method for simple cut to length line

The product collection method for a simply cut to length line depends on the specific needs of the customer for that type of line. Collection methods can be broadly categorized as manual collection, simple lifting collection, and automatic palletizing. For in-house equipment with thinner materials, shorter cutting lengths, and lower production volumes, manual collection and palletizing are common options. For simple cut to length lines, if the cutting length exceeds 600mm and exceeds the range of manual gripping, a forklift can be considered for pick-up. For high-volume production or material suppliers who need to process materials with wide variations in width and length, automatic palletizing is the optimal choice.

|

|

|

Simply cut to length lines, due to their flexibility, compact footprint, and high degree of automation, are an ideal choice for many small and medium-sized enterprises and new entrants into the industry. By rationally configuring each component, simple cut to length lines can meet the processing needs of diverse materials and improve production efficiency. Furthermore, a deep understanding of customer needs will help manufacturers provide more precise simply cut to length line solutions, securing a niche in the competitive market.

KINGREAL STEEL SLITTER hopes this article helps you understand the basic configuration of a simple cut to length line. If you have further questions or inquiries, please contact KINGREAL STEEL SLITTER for further discussion.