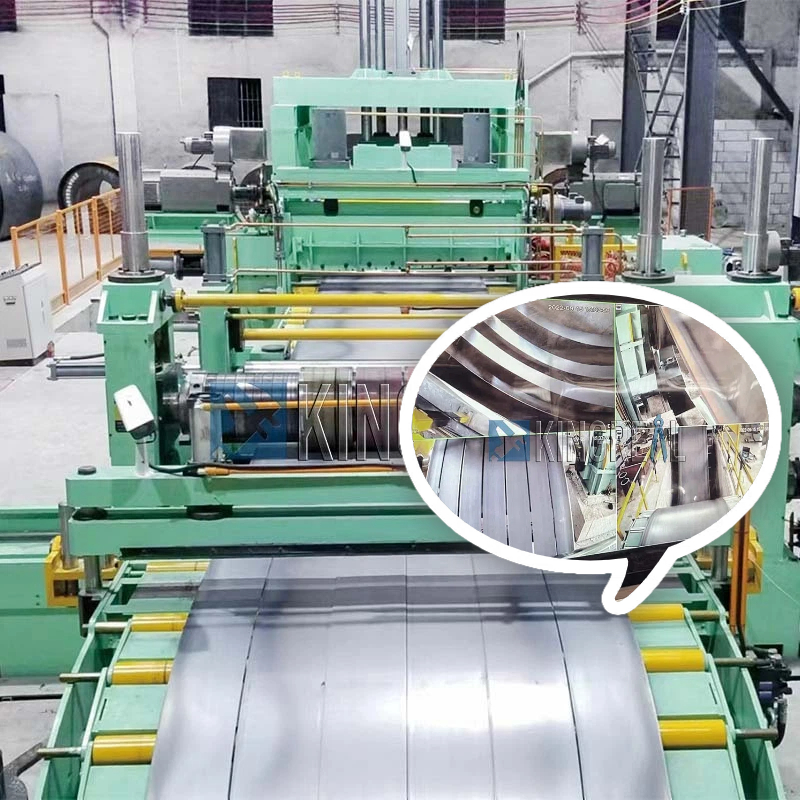

Heavy gauge slitting line is designed specifically for processing metal coils ranging in thickness from 6 to 25 mm. It boasts a wide range of material compatibility, processing a variety of metals, including hot-rolled steel, cold-rolled steel, stainless steel, galvanized steel, PPGI, and copper. These heavy gauge slitting machines are widely used in heavy industries such as steel-making, automotive production, rail transportation, and industrial metal framing, etc.

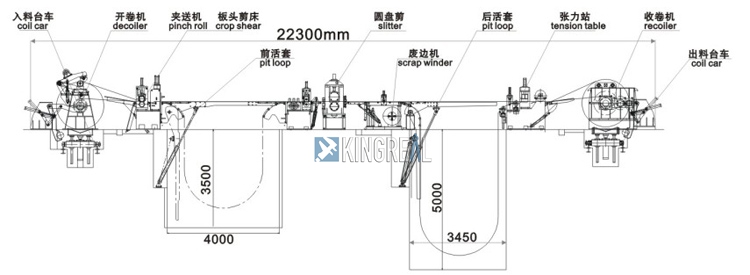

The entire process of a heavy gauge slitting machine begins with the unwinding of the coiled metal material by the decoiler, ensuring smooth feeding for subsequent processing steps. The unwound steel plate then enters the straightening machine, where internal stresses are effectively eliminated, resulting in a smooth and uniform surface. This step is crucial for ensuring accurate cutting in the subsequent cutting process.

The straightened steel plate is then conveyed to the slitting unit. With slitting tolerance of ±0.05 mm, the precision blades fitted in this gadget precisely slice steel sheets into small strips of the needed width. Slitting mistakes and plate warpage are reduced by this high-precision slitting procedure, hence guaranteeing the quality of the narrow strip.

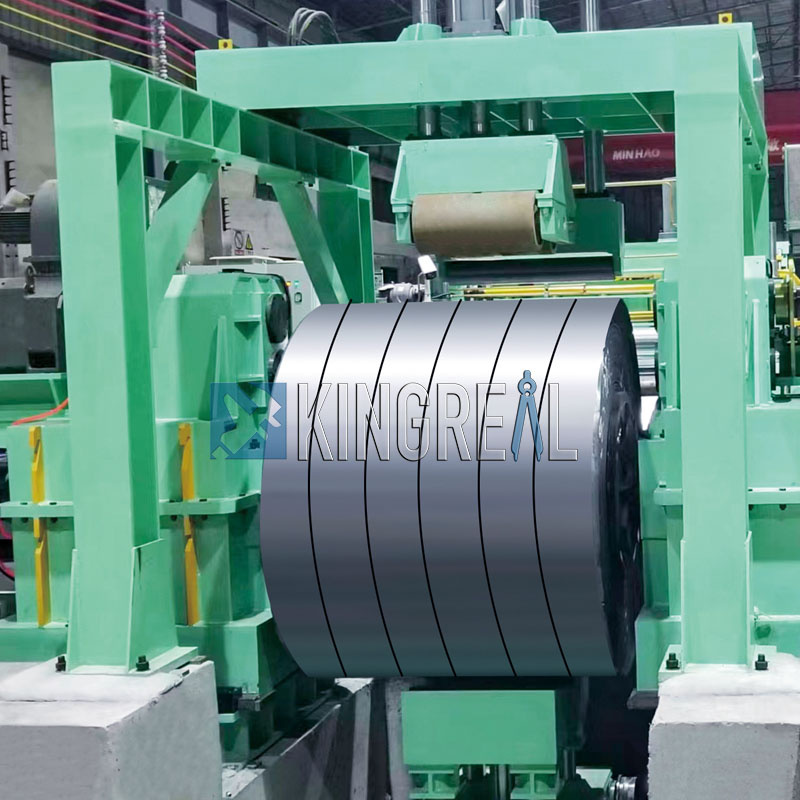

Following slitting, the metal strip is precisely delivered into the recoiler using a guide mechanism, where it is coiled into a narrower coil therefore it becomes packaged, handled, and carried more simply.

After slitting, the metal strip is accurately fed into the recoiler via a guide system, where it is wound into a narrower coil, making it easier to package, handle, and transport.

1) High precision slitting for heavy gauge slitting line

KINGREAL STEEL SLITTER heavy gauge slitting machines are equipped with advanced slitting technology and a sophisticated control system, enabling extremely high-precision control during the slitting process. Heavy gauge slitting machine’s slitting tolerance can be stably controlled to ±0.05 mm, significantly reducing the probability of slitting errors.

2) High efficient slitting for heavy gauge slitting line

This heavy gauge slitting machine is automatic, enabling a continuous and rapid slitting process. Furthermore, KINGREAL STEEL SLITTER heavy gauge slitting machine is designed with actual production needs in mind, allowing for quick blade changes and adjustments to equipment settings, effectively reducing heavy gauge slitting line downtime and further improving overall production efficiency.

3) Strong adaptability for heavy gauge slitting machine

The KINGREAL STEEL SLITTER heavy gauge slitting line not only can process several types of metal coils but also accommodate sheet metal of different thicknesses. Heavy gauge slitting line’s great flexibility makes it suitable for use in many sectors, including construction and building materials, domestic appliance manufacture, and vehicle manufacturing, therefore satisfying the different processing requirements of various customers.

4) Stable operation for heavy gauge slitting machine

The heavy gauge slitting line has a sturdy chassis and a reinforced mechanical system to guarantee consistent performance under continuous, intense working conditions. Whether in long-term continuous manufacturing processes or in high-load processing situations, the heavy gauge slitting machine always performs admirably, hence lowering heavy gauge slitting line, reducing maintenance expenses and failure rates.

|

|

|

1)Clarify your processing needs

You first need to clearly establish your processing requirements before choosing a heavy gauge slitting machine. More particularly, you should bear in mind these factors:

-Material Type: Requirements for tool performance and overall structural design vary for several metal materials, including carbon steel, stainless steel, aluminum, and copper, in the heavy gauge slitting line. And it follows that it is essential to make sure the chosen heavy gauge slitting machine fits the kind of metal material you need to handle.

-Material Thickness and Width: Accurately determine the thickness range and width specifications of the metal materials your needs to process, and use this as a basis for selecting the appropriate heavy gauge slitting line model. For example, the KINGREAL STEEL SLITTER heavy gauge slitting machine typically handles material thicknesses ranging from 6 to 25 mm. If your needs to process thicker plate, you can contact KINGREAL STEEL SLITTER professional engineers for customized heavy gauge slitting machine solutions.

-Production Volume: Select heavy gauge slitting line that matches your expected production scale and output requirements. Generally, heavy gauge slitting machine for high production needs requires a higher degree of automation and faster slitting speeds to meet the efficiency requirements of large-scale production.

2)Focus on brand and reputation

Choosing a brand and supplier with high market recognition and a good reputation is crucial for ensuring the quality of your heavy gauge slitting line and subsequent after-sales service. KINGREAL STEEL SLITTER not only provides customers with high-quality heavy gauge slitting machine, but also offers comprehensive service support, covering heavy gauge slitting line installation and commissioning, operator training, regular heavy gauge slitting machine inspections, and routine maintenance. Furthermore, KINGREAL STEEL SLITTER can promptly provide customers with all necessary accessories, effectively eliminating customer concerns during heavy gauge slitting line operation.

3) Pay attention to heavy gauge slitting machine performance

Heavy gauge slitting line performance is a key factor in determining whether it can meet your production needs. During the selection process, focus on the following points:

-Slitting Accuracy: Carefully confirm the heavy gauge slitting machine's slitting tolerances to ensure it meets your production precision requirements.

-Slitting Speed: While ensuring slitting accuracy, choosing heavy gauge slitting machine with a faster slitting speed can help improve overall production efficiency and shorten production cycles.

-Degree of Automation: Heavy gauge slitting machines with a high level of automation can effectively reduce manual intervention and minimize the impact of human factors on the production process.

4) Comprehensively consider price and cost-effectiveness

You should not only consider the initial cost of the heavy gauge slitting machine when assessing pricing but also thoroughly evaluate the several long-term use costs include maintenance, energy usage, and tool replacement expenditures. By carefully considering the long-term operating expenses and the initial investment, you may select heavy gauge slitting line with the greatest cost-benefit.

|

|

|