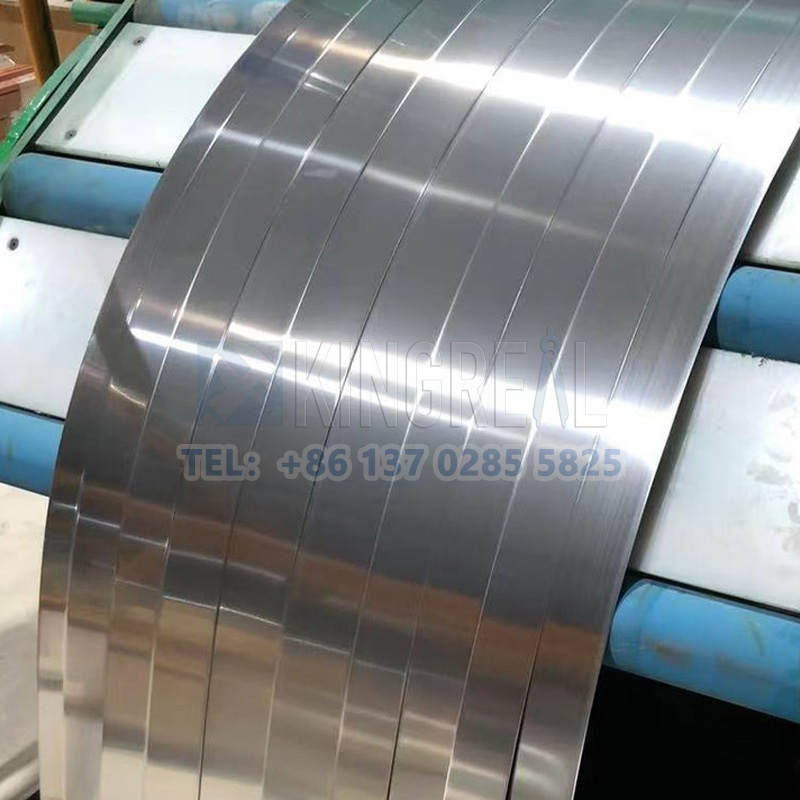

Steel coil slitting lines process a variety of metal materials, such as aluminum, stainless steel, cold-rolled steel, hot-rolled steel, silicon steel, and PPGI, through processes such as uncoiling, slitting, and rewinding. They are capable of producing narrow strips that meet customer specifications. As market demand for steel coil slitting machines increases, customer production scales continue to expand, and a variety of projects emerge, various types of steel coil slitting lines have been introduced to meet customer needs. This article will provide a detailed introduction to steel coil slitting lines, hoping to provide a deeper understanding of the steel coil slitting machines.

A steel coil slitting line is an automated coil processing equipment designed to unwind and cut wide strips into desired widths or lengths with high speed and precision. Modern steel coil slitting lines typically integrate uncoiling, slitting, rewinding, automatic tool changing, and feeding and stacking systems to optimize high-precision and efficient production processes. Using a rigorously engineered circular steel coil slitting machine, steel coil slitting lines are widely used in the metalworking industry and are popular for their reliability and efficiency.

●Main Components of Steel Coil Slitting Machine

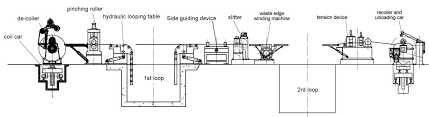

Steel coil slitting lines typically include three main coil handling systems:

Unwinding system: Loads and straightens wide coils to improve surface quality.

Slitting system: Cuts the wide coil into narrow strips of the desired width using a cutting tool.

Rewinding system: Rewinds the cut strips and collects them in a stacking tool.

This structure enables steel coil slitting machines to quickly produce large quantities of products without the need for secondary operations or other finishing equipment.

|

|

Coiling → Unwinding → Leading → Pinch and Rough Leveling → Cutting → Scrap Collection → Swinging Bridge → Web Correction and Feeding → Slitting → Scrap Coiling → Swinging Bridge → Tension Station → Rewinding → Unloading

3.1 Unwinding for steel coil slitting line

During the unwinding process of a steel coil slitting machine, the raw material is fed into the unwinding system via a coil loader or an automated robotic feeder. This system typically utilizes a single-ended, extended mandrel design and is suitable for handling light to heavy loads. The unwinding system ensures a smooth, surface-free coil as it unwinds.

The decoiler's design allows it to handle metal coils with widths ranging from 40 to 60 cm. For materials with larger inner diameters, filler sheets can improve efficiency. Filler rings are widely used to handle coils with larger inner diameters.

3.2 Slitting for steel coil slitting line

During the slitting process, the metal coil is loaded into the cutting area and cut by two parallel mandrels and meticulously machined rotating cutters. The cutting accuracy of a steel coil slitting machine directly impacts the quality of the final product, so the selection of cutters and the setting of cutting parameters are crucial.

Equally important during the cutting process are edge trimming and waste handling. Modern steel coil slitting lines are often equipped with rubber stripping rings and a waste reel to effectively manage waste during production. The waste reel collects the waste under tension, ensuring efficient operation.

3.3 Rewinding for steel coil slitting machine

In some steel coil slitting lines, a rewinding system is used to handle coils that require bending or deformation to create custom profiles. The rewind system allows for the bundling of cut-to-length coils onto the reel, ensuring the quality and stability of the finished product.

Steel coil slitting lines are widely used in various industries, including but not limited to:

Steel coil slitting machine in automotive manufacturing: Used in the production of body structural parts and accessories.

Steel coil slitting line in construction industry: Provides metal materials for door and window frames, structural supports, and other applications.

Steel coil slitting line on electrical appliance manufacturing: Used in the production of appliance housings and internal components.

Steel coil slitting machine in home appliance industry: Provides metal parts and structural supports for home appliances.

With the increasing market demand for steel coil slitting lines, various new types of steel coil slitting machines have emerged to meet the production needs of diverse customers.

|

|