A steel cut to length machine is a machine used to process metal coils through processes such as uncoiling, leveling, sizing, and shearing into flat sheets of desired lengths, and then stacking them. Steel cut to length line is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various coated metal materials. Steel cut to length machines come in various types, depending on the thickness and material type of the material being processed, as well as the customer's production efficiency requirements. This article will provide a detailed overview of each aspect of a steel cut to length line, providing comprehensive guidance.

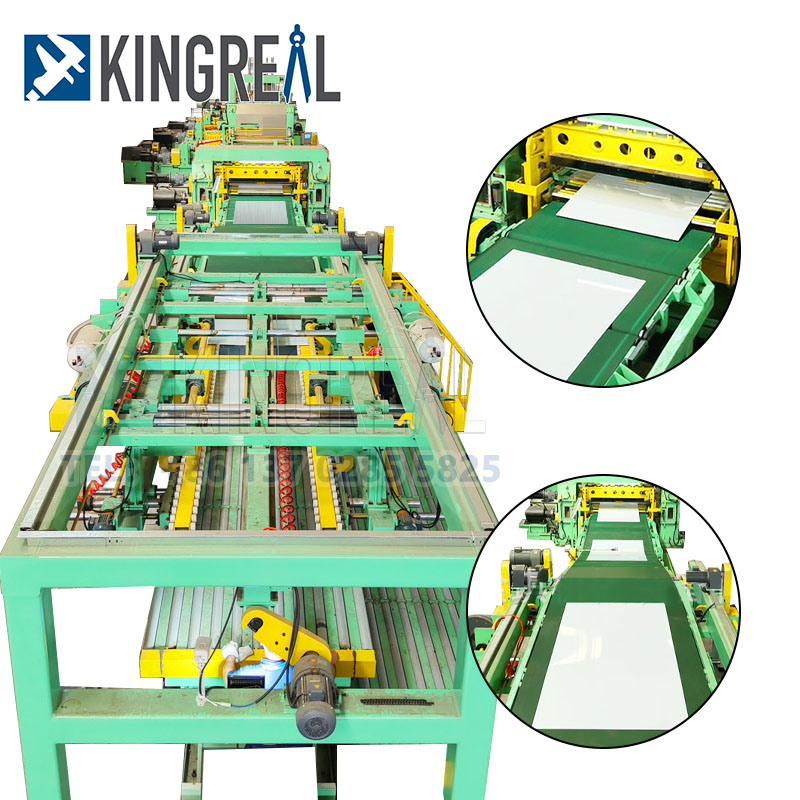

A steel cut to length machine primarily consists of the following components:

Loading trolley for steel cut to length line: Transports the coil to the decoiler.

Decoiler for steel cut to length machine: Unwinds the coil, preparing it for further processing.

Leveling for steel cut to length line: Ensures the flatness of the sheet to meet shearing requirements.

Feeder for steel cut to length machine: Transports the leveled sheet to the shearing machine.

Shearing machine for steel cut to length line: Performs the shearing operation, cutting the sheet to the desired length.

Conveyor for steel cut to length machine: Transports the cut sheet to the stacking machine. Stacking devices neatly stack sheared sheets for easy processing.

These devices typically integrate mechanical, electrical, and hydraulic systems, offering high performance and automation, along with simple and reliable operation. Steel cut to length lines achieve high standards of cut-to-length accuracy and sheet flatness, ensuring neat stacking.

1. Classification by Material Type

For ferrous metals such as carbon and low-alloy steel, the shearing thickness typically ranges from 0.5 to 25 mm. Equipped with high-strength shearing tools and leveling devices, they are primarily used in areas such as building steel structures, automotive chassis, and machinery manufacturing.

Stainless steel cut to length machine:

Using wear-resistant tools (such as carbide) and scratch-resistant conveyor belts to prevent oxidation on the stainless steel surface, they achieve a shearing accuracy of ±0.1 mm. They are suitable for applications requiring high surface quality, such as kitchenware, medical devices, and chemical equipment.

Non-ferrous metal cut to length line:

These cut to length machines can be used to shear coils of aluminum, copper, and other materials to meet specific customer needs. These cut to length machines are typically equipped with anti-static devices and flexible conveying systems. They are suitable for applications in aerospace, electronic components, and for processing lithium battery electrodes and high-frequency circuit boards.

|

|

|

2. Classification by Level of Automation

Manual steel cut to length line:

Use manual loading and positioning, mechanical shearing, and low efficiency (≤20 cycles/minute). They are suitable for small-batch, multi-specification custom processing and are commonly found in small fabrication plants and repair shops.

Semi-automatic steel cut to length line:

Automatic uncoiling and leveling, manual positioning and shearing, equipped with a simple PLC control system, offer an efficiency of 30-50 cycles/minute and are suitable for small and medium-sized sheet metal fabrication plants.

Fully automatic steel cut to length machine:

Fully automated the entire process (uncoiling, leveling, sizing, shearing, and stacking). Utilizing a CNC system (such as the Siemens S7-300), they can achieve an efficiency of up to 80 cycles/minute with a positioning accuracy of ±0.3mm. They are widely used in automotive OEMs, home appliance panel production lines, and large steel structure plants.

3. Classification by Processing Accuracy

Ordinary precision steel cut to length machine:

Shearing tolerance is ±0.5mm/m, flatness ≤3mm/m, suitable for building panels and general structural parts.

High precision steel cut to length line:

Shearing tolerance is ±0.1mm/m, flatness ≤1mm/m. These steel cut to length machines are typically equipped with a servo feed system and laser positioning, suitable for automotive covers and precision instrument housings.

Ultra-precision steel cut to length line:

Shearing tolerance is ≤±0.05mm/m. These lines utilize air bearing conveying and CNC hydraulic shearing, suitable for aerospace panels and microelectronic substrates.

4. Classification by Shearing Method

Fly shearing cut to length machine:

Utilizing highly reliable mechanical properties and a mature and stable electrical control system, these fly shearing cut to length machines achieve high-efficiency, high-quality shearing of sheet metal. They feature continuous, fast, and leveling of the entire line, and high cut-to-length accuracy.

Rotary shearing cut to length line:

The rotary shearing cut to length machine rotates at high speed to cut, eliminating marks caused by shearing stops. These rotary shearing cut to length machines are suitable for shearing operations requiring high surface quality.

Swing shearing cut to length machine:

Easily switch tools and combine precise swing angles to achieve high-precision shearing of special-shaped sheet metal. With an swing range of 0-30°, it's suitable for producing rectangular, trapezoidal, and parallelogram-shaped sheet metal.

Fixed shearing cut to length line:

The fixed shearing cut to length machine stops feeding at a preset length to ensure cutting accuracy. Therefore, compared to other types of steel cut to length machines, this type of machine has a slower production speed.

|

|

|

When selecting steel cut to length machine, it's recommended to focus on the following parameters:

-Speed compatibility for steel cut to length line: The steel cut to length machine cycle must match the upstream unwinding speed to ensure production efficiency.

-Tool compatibility for steel cut to length line: Blade material should meet HRC58-62 standards, with Cr12MoV or DC53 being the preferred choice.

-Control system for steel cut to length machine: A PLC system supporting MODBUS-TCP is recommended to ensure seamless integration with the MES system.

-Safety for steel cut to length line: The dual-column light barrier should meet IP67 rating, and the emergency stop response time should be less than 0.1 second to ensure safe operation.

-Customization capabilities for steel cut to length machine: High-quality suppliers should be able to provide customized roll diameters (ranging from Ø80-160mm) to meet diverse customer needs.

The following aspects should be emphasized during the full lifecycle management of the steel cut to length line:

-Weekly inspection for steel cut to length machine: Regularly check the hydraulic system pressure (maintained at 14-16 MPa) and the gearbox oil level (the sight glass should be at the 2/3 mark).

-Quarterly maintenance for steel cut to length line: Replace the grease in the work roll bearings; NLGI#2 lithium-based grease is recommended.

-Annual inspection highlights for steel cut to length machine: Leveling roll coaxiality must be corrected to less than 0.02 mm, and the servo motor encoder must be calibrated.

-Intelligent monitoring for steel cut to length line: Install vibration sensors and set abnormal warning thresholds (e.g., alarm when acceleration exceeds 0.5g) to ensure safe equipment operation.