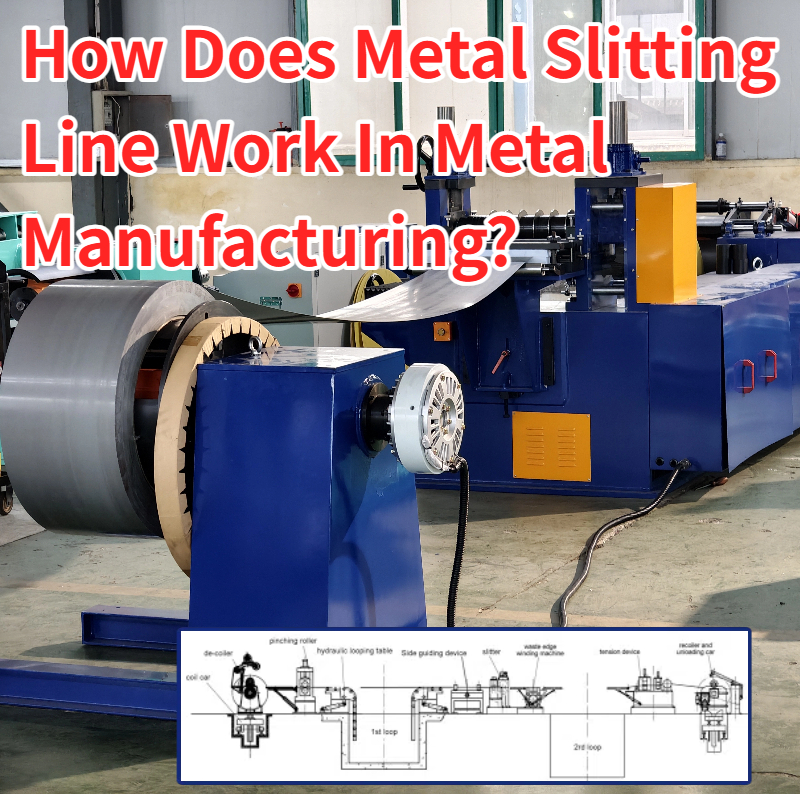

Almost everywhere and absolutely essential in metal manufacture are metal slitting machines. Along with in the building business to create building cladding and roofing materials, they are used in several other industries including the food packaging, automotive, and electrical sectors. Metal slitting line guarantee great quality and efficiency throughout a broad spectrum of goods by accurately cutting big coils into thin strips.

-Metal slitting line in construction industry: Building siding and roofing materials benefit from the small strips made by metal slitting machines. These materials guarantee the long-term use of buildings by providing great waterproofing and thermal insulation in addition to visual appeal.

-Metal slitting machine in automotive industry: Metal slitting lines create body panels, heat shields, and exhaust systems among other components used in vehicle manufacturing. These parts' precision and longevity have a direct bearing on the vehicle's safety and lifespan.

-Metal slitting line in electronics industry: Metal slitting machines create connectors, terminals, heat sinks, and shielding. High precision is frequently needed for these parts to guarantee the appropriate operation and security of electronic equipment.

-Metal slitting machine in food packaging: Metal slitting lines help to create food cans, trays, and aluminum foil to guarantee freshness and safety.

1. Precision and consistency for metal slitting machine

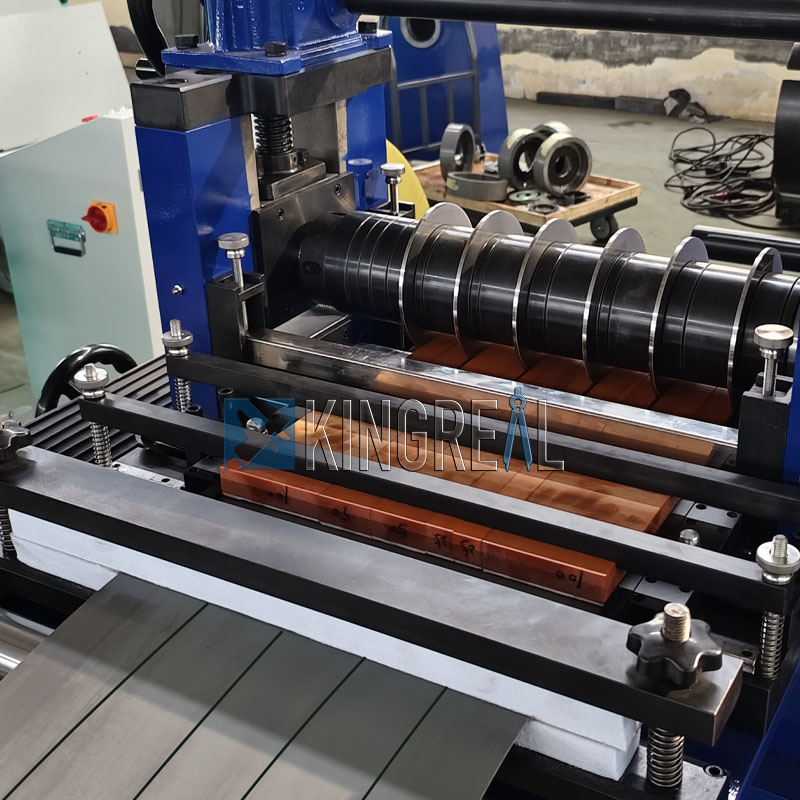

High precision coil width generation is made possible by automated metal slitting lines and the capacity to change the blade spacing. Moreover, the uniformity of the slitting procedure guarantees uniform quality across all coils made. From slice to cut, the automated slitting process guarantees consistency, therefore producing homogeneous quality along the length of the slit material. Because of this high degree of precision, metal slitting line is especially useful in challenging sectors.

2. Material utilization for metal slitting machine

Manufacturers may make full use of their raw resources thanks to metal slitting line. Reducing trash and maximizing usage of each sheet by exact width cutting metal sheets to meet the specifications of every application minimizes waste and guarantees maximum use of each sheet. This also helps companies contribute to waste reduction and is ecologically friendlier as well as being economical.

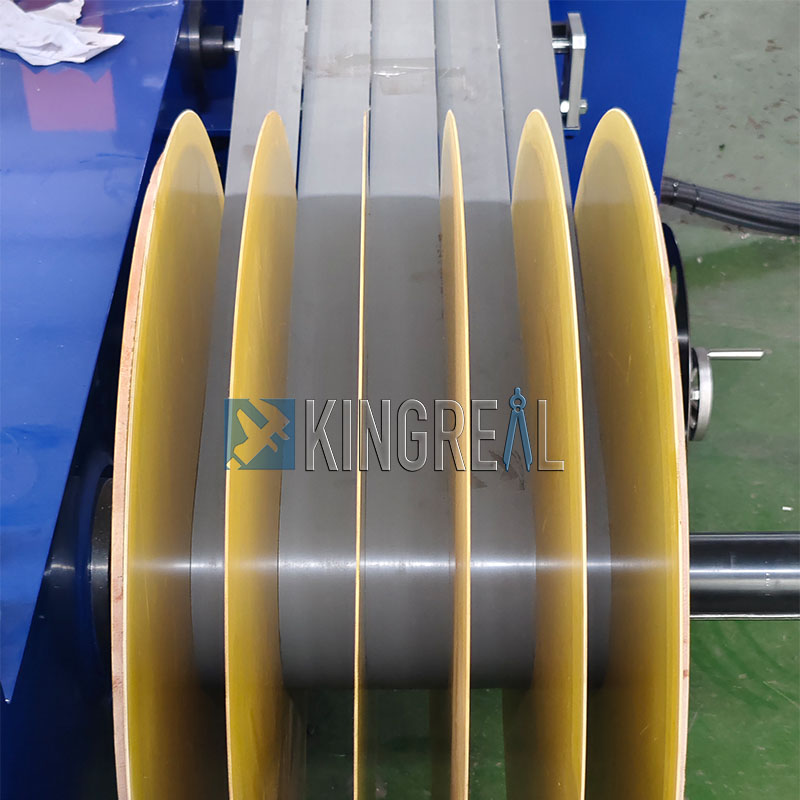

3. Scalability and versatility for metal slitting machine

Metal slitting machines are ideal for small custom orders as well as for major output because they provide volume production flexibility. Moreover, the method is flexible and can handle stainless steel, aluminum, copper, brass among other metals. This lets producers change to changing market conditions by satisfying a broad spectrum of consumer demands and specifications. For example, the construction industry may require large quantities of roofing materials, while the electronics industry may require small batches of parts with specific specifications. The flexible configuration of metal slitting machines allows both of these needs to be met.

4. Highly efficient metal slitting machine

Faster and more accurate slitting of coils is made possible by automated metal slitting machines, which also eliminate physical labor or other techniques, hence increasing consumer manufacturing efficiency. Automation guarantees effective running at every stage of production by not only shortening production cycles but also lowering the likelihood of human mistake.

This enhanced production efficiency enables businesses to react more fast to consumer orders and meet market demands, hence increasing consumer satisfaction.

|

|

|

5. Strict tolerance control for metal slitting line

Strict tolerance control is necessary for precision cutting using metal slitting machine. Advanced sensors and feedback mechanisms monitor the slitting process in real-time to guarantee that slit width and edge quality fulfill the necessary requirements. For sectors needing high-precision components, including electronics and medical devices, this feature is absolutely vital.

In the medical field, for instance, even the tiniest mistake can affect device performance and patient safety.Therefore, metal slitting machines are particularly important in such applications.

6. Improve edge quality for metal slitting line

Superior edge quality is attained by metal slitting machines using modern slitting techniques. Minimization of burrs by precision-ground cutting blades and unique slitting rollers guarantees smooth, clean edges on cut sheets. This improved edge quality removes the necessity of more finishing processes, thereby saving both time and money.

Edge quality has a direct effect on following assembly and performance in the automotive and electronics sectors, so high-quality metal slitting machines are especially crucial.

7. Flexible metal slitting machine configurations

Customization of metal slitting line caters to particular application needs. These metal slitting machines can be set to maximize performance for a range of sectors and materials, from the number of cutter heads to the width range and coil handling capacity. This adaptability lets producers customize their metal slitting lines to their individual requirements, therefore guaranteeing best production results.

Some sectors, for instance, may need thicker materials while others may need processing very thin metallic materials. These many needs can be met by the adaptable setup of metal slitting line.

|

|

|

Metal manufacturing depends on metal slitting machines in a way that cannot be replaced. Their benefits in accuracy, material use, efficiency, and flexibility make them an absolute necessity in contemporary manufacturing. Whether in food packaging, electronics, cars, or building projects, metal slitting line guarantees excellent goods and effective production.