A heavy gauge cut to length machine is a machine specifically designed to precisely cut metal coils ranging in thickness from 6 to 20 mm to customer-specified lengths. Various industries, including construction and production, depend on this heavy gauge cut to length machine. Demand for heavy gauge cut to length machines has continued to grow in recent years as a result of the rapid industrialization, hence fueling technology innovation and development in this form of heavy gauge cut to length line.

-Highly automated heavy gauge cut to length line: PLC-controlled all parts provide a high level of dependability and automation. This automatic design lowers errors brought on by human labor in addition to boosting manufacturing efficiency.

-Digital speed control system for heavy gauge cut to length line: This system's quick response time and superb dynamic and static performance enable quick adaptation to changes in production demands.

-High-precision encoder for heavy gauge cut to length machine: Equipped with a high-precision encoder, the heavy gauge cut to length line properly controls the plate's measurement accuracy and working speed guarantee exact cuts every time and help to satisfy customers' exacting needs.

-Automatic measurement and display for heavy gauge cut to length line: The heavy gauge cut to length line automatically measures and displays the cut length and volume, enabling operators to track output development live.

-Safety features for heavy gauge cut to length line: It guarantees operator safety by enabling quick action in the event of an emergency with emergency stop and alarm capabilities.

-Surface finishing device for heavy gauge cut to length machine: Equipped with a brush or vacuum cleaner, it is used to finish the material surface and enhance the surface quality of the finished product.

-Elevating conveyor for heavy gauge cut to length line: Continuously operates at the inlet, ensuring stable material transport and improving production efficiency.

-Tracking shearing and moving shearing: Enable non-stop operation, improve production continuity, and reduce unnecessary downtime.

-Customization options for heavy gauge cut to length machine: Optional start-stop shears, simple stackers, automatic stackers, and trimming devices are available to meet the needs of various production environments.

|

|

|

When designing heavy gauge cut to length machines, KINGREAL STEEL SLITTER always prioritizes the customer's specific production needs and provides comprehensive customization. The design process includes the following key steps:

1. Requirements analysis for heavy gauge cut to length line

First, KINGREAL STEEL SLITTER will engage in thorough conversations with the customer to get their particular needs for metal coils, including substance type (e.g., steel, aluminum Requirements for alloy, hot-rolled), coil thickness, width, weight, production efficiency, and plate accuracy Ensuring the later design satisfies the customer’s precise needs, this step forms the foundation of the whole design process.

2. Heavy gauge cut to length machine design plan

After clarifying the customer's requirements, KINGREAL STEEL SLITTER design team will use CAD software to conduct a detailed design and create a 3D model. The design plan will include the specific design of various components such as the heavy gauge cut to length line frame, cutting tools, and control system, and simulation analysis will be performed to ensure that the expected performance is achieved in actual operation.

3. Tool design and selection for heavy gauge cut to length machine

Tools are one of the most critical components in a heavy gauge cut to length line, directly affecting cutting quality and efficiency. Based on the hardness and precision requirements of the customer's processing materials, KINGREAL STEEL SLITTER will carefully select the material and type of tool to ensure excellent wear resistance and cutting performance during high-intensity cutting.

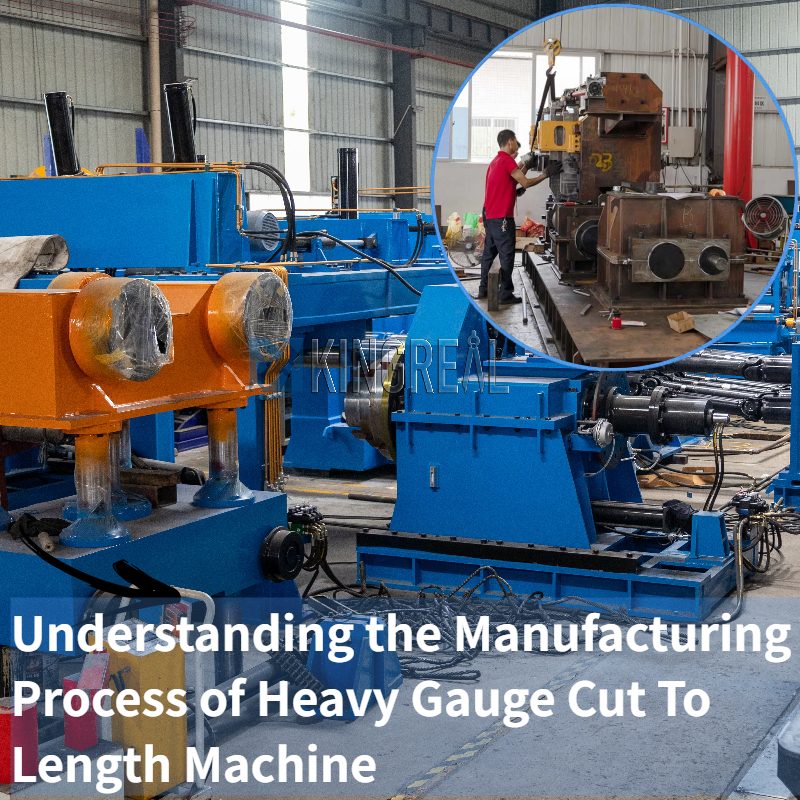

After the design is confirmed, KINGREAL STEEL SLITTER officially enters the manufacturing phase of the heavy gauge cut to length machine. The manufacturing process adheres to strict procedures to ensure quality at every stage.

1. Manufacturing process of heavy gauge cut to length line

KINGREAL STEEL SLITTER manufacturing team has over 15 years of industry experience and is proficient in the production process of heavy gauge cut to length machines. The manufacturing process includes the following steps:

Material Procurement: Procurement of standard raw materials based on the design drawings ensures material quality.

Machining: Machining using advanced CNC equipment ensures precise dimensions and shapes of each component.

Welding and Assembly: After machining each component, welding and assembly are performed to ensure structural stability and reliability.

Surface Treatment: Surface treatment is applied to the assembled equipment to prevent rust and corrosion, thereby increasing its service life.

2. Testing and quality control for heavy gauge cut to length line

After the heavy gauge cut to length machine is manufactured, KINGREAL STEEL SLITTER conducts comprehensive testing and quality control. This phase includes:

Appearance Inspection: A comprehensive inspection of the heavy gauge cut to length line's appearance is performed to ensure there are no obvious defects.

Functional Testing: The heavy gauge cut to length machine is put into actual operation, with coils inserted for real-world testing to verify cutting performance and accuracy.

Performance Evaluation: This evaluation ensures that all indicators meet design requirements, guaranteeing heavy gauge cut to length line reliability and stability.

3. Customer feedback and improvement for heavy gauge cut to length line

After completing heavy gauge cut to length machine testing, KINGREAL STEEL SLITTER will communicate the test results to the customer to ensure customer satisfaction. If the customer has any feedback or suggestions for improvement, KINGREAL STEEL SLITTER will promptly implement necessary adjustments and improvements to ensure that the final delivered heavy gauge cut to length machine perfectly meets the customer's needs.