Metal slitting machines produce various types of metal coils for secondary processing, which are used for market sales or for the production of metal products in their own factories. KINGREAL STEEL SLITTER metal slitting machine can be customized according to the customer's production needs, from unwinding, leveling, slitting, scrap winding to collection machine device.

KINGREAL STEEL SLITTER metal slitting machine can produce narrow strips of customer-specific widths from steel, stainless steel, aluminum, copper, and other metal materials with a thickness range of 0.2-16mm. It can slit up to 40 strips simultaneously. The metal slitting machine's production speed is adjustable, reaching a maximum of 230m/min.

Metal slitting machine has the main functions of decoiler, straightener, coil slitting, belt tension, and rewinding. Metal slitting machine main working equipment includes a feeding trolley, unwinding machine, leveling machine and power, front loop,metal slitting machine and power, waste edge collecting machine, rear loop, belt tension machine, winding machine, auxiliary support, unloading device, hydraulic system, electrical system, etc.

KINGREAL STEEL SLITTER metal slitting line adopts PLC centralized control and human-machine interface display. It is an electronic control system dominated by brands such as Siemens and Schneider, which can be freely set according to the user's order quantity, number of strips, different strip specifications, strip speed and other parameters.

KINGREAL STEEL SLITTER, as an experienced metal slitting machine manufacturer and supplier, owns its own factory in China, allowing for comprehensive control over machine design, research and development, manufacturing, and testing, ensuring the provision of high-quality metal slitting machines to customers. Contact KINGREAL STEEL SLITTER today to get the latest price list.

1. Steel coil Product

Raw material:GI/ carbon steel

Material thickness: 0.25-2 mm(as your request)

Coil weight: ≤ 10 Tons

Coil width: 500-1500 mm

Simple steel coil slitting machine line Metal sheet slitting slitter equipment

2.Metal Slitting Line Hydraulic Decoiler

Usage: Support the coil and the hydraulic drives it expand and shrink.Loading the coil actively.

Work type: hydraulic

Loading capacity: 20Tons

Component: Base, break system, main shaft, machine frame, diagonal bracing type expand and shrink system, hydraulic oil pump,motor, press coil system,etc.

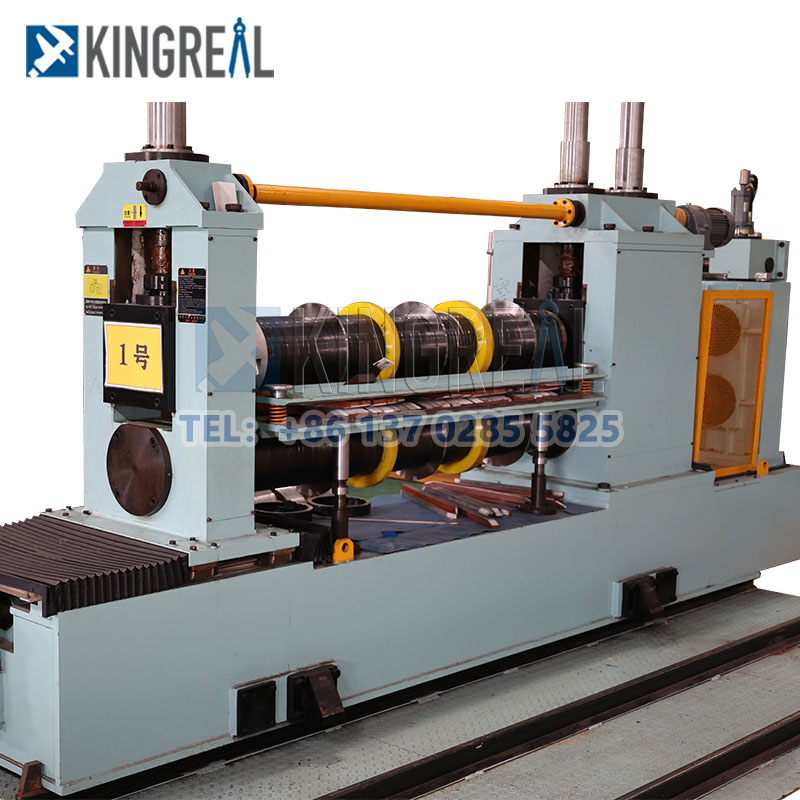

3.Main Metal Slitting Machine

Usage: Main Metal Slitting Machine

has guiding device in each side and feeding wipe brush, to finished strips and prevent them from jumping and improve the slitting precision.

The metal slitting system has active shear and pull shear and can switch them meet all of precision requirement with different thickness.There is also have scrap winder device.

Cutter shaft diameter: Φ 150 mm

Cutter shaft material: 40 Cr with tempering treatment

Cutter material: 9CrSi

Metal Slitting precision: ≤±0.05 mm

4.Metal Slitting Rewinding Device

Usage: Metal slitting rewinding device cooperates with the finished steel strips after first pre-dividing and second dividing to insure the even and tight quality of recoiler. Recoiling tension adjustable, recoiling speed adjustable.

Loading capacity: 10 Tons

Inner hole diameter: Φ508 mm

Component: Base,main shaft,machine frame, hydraulic diagonal bracing type expand and shrink system,adjustable-speed motor(45KW),reducer,screw rod, dividing shaft,etc.

1.High Precision Lever For Metal Slitting Line

The metal slitting machine leveling machine is a device used to level uneven steel plates. The leveling machine adopts a single-layer roller structure with 2 upper and 3 lower rollers.

Each leveling roller of the metal slitting machine leveling machine is fine-turned, tempered, chrome-plated, and ground to ensure surface hardness and finish, and to achieve the best leveling effect. The leveling rollers are independently driven by the distribution gearbox through universal couplings, and the single machine can move forward and reverse.

2.Loop Bridge For Metal Slitting Machine

Loop Bridge For Metal Slitting Machine is used to control the synchronization and buffering of the steel belt speed between the slitter and the feeder. The table is made of nylon plate to ensure that the plate surface will not be scratched. Three pairs of electric eyes control the position of the steel belt in the loop pit to maintain sufficient storage capacity in the pit.

Based on the thickness of the coil and the customer's factory area, Loop Bridge For Metal Slitting Machine will be available as an option for customers to choose

3.Metal Slitting Machine Clamping Machine

The metal slitting machine clamping machine can be used for winding machine to cut in sections, and flexibly handle the problem of winding large and small rolls. Prepare for the subsequent process. It is driven by an oil cylinder.

When cutting plates of different thicknesses, the gap between the scissors blades can be adjusted manually. The blades of the four-sided scissors can be replaced and used alternately. Cut from top to bottom.

1. Meet various coil processing needs.

KINGREAL STEEL SLITTER metal slitting machine can process aluminum coil, stainless steel coil, galvanized coil, silicon steel coil and hot-rolled coil, etc., with a thickness range of 0.2-16MM and a coil width of 600-2500MM. It can be slid into specified widths according to the customer's processing needs and finally rolled up.Send us your coil parameters, and KINGREAL STEEL SLITTER will help you design the metal slitting machine production line drawings and production technology solutions.

2.High Speed Metal Slitting Line.

KINGREAL STEEL SLITTER metal slitting machine can reach 150M/Min to 200M/Min, high-speed metal slitting machine design can help large coil processing factory customers effectively improve production efficiency and create higher profits. KINGREAL STEEL SLITTER has increased the production speed of the metal slitting machine by adding fully automated functions to the knife seat configuration, unwinding and rewinding auxiliary devices, etc.

3.Provide metal slitting machine after-sales installation service.

KINGREAL STEEL SLITTER has formed a professional after-sales engineer team to assist in the assembly, installation and production commissioning of the metal slitting line, ensuring that customers can run the metal slitting line smoothly. At the same time, we provide professional metal slitting machine operation and maintenance guidance to the operators in the customer's factory.

|

|

1. How to get a complete quotation for metal slitting machine?

KINGREAL STEEL SLITTER has a professional technical team to follow up on customers' coil processing needs and design drawings and technical solutions for metal slitting machines. Please provide the raw materials, thickness, width and coil weight of the coils and other parameters.

2.Can the various components of the metal slitting machine be customized?

Of course! Each component of the metal slitting machine will be customized based on the customer's coil parameters, slitting speed, coil processing output, factory area and layout and other factors. KINGREAL STEEL SLITTER will provide customers with the best metal slitting machine production solutions

3. How to ensure the quality of metal slitting machine?

KINGREAL STEEL SLITTER has a professional production team and a complete production workshop. From the procurement of raw materials to CNC processing and component casting, a professional technical team is responsible for the entire process.

At the same time, a complete metal slitting machine quality inspection system is established. After the metal slitting line is manufactured, the accuracy of the components will be tested by idling in the factory. And customers will be invited to the factory for on-site inspection and learning.

|

|

|