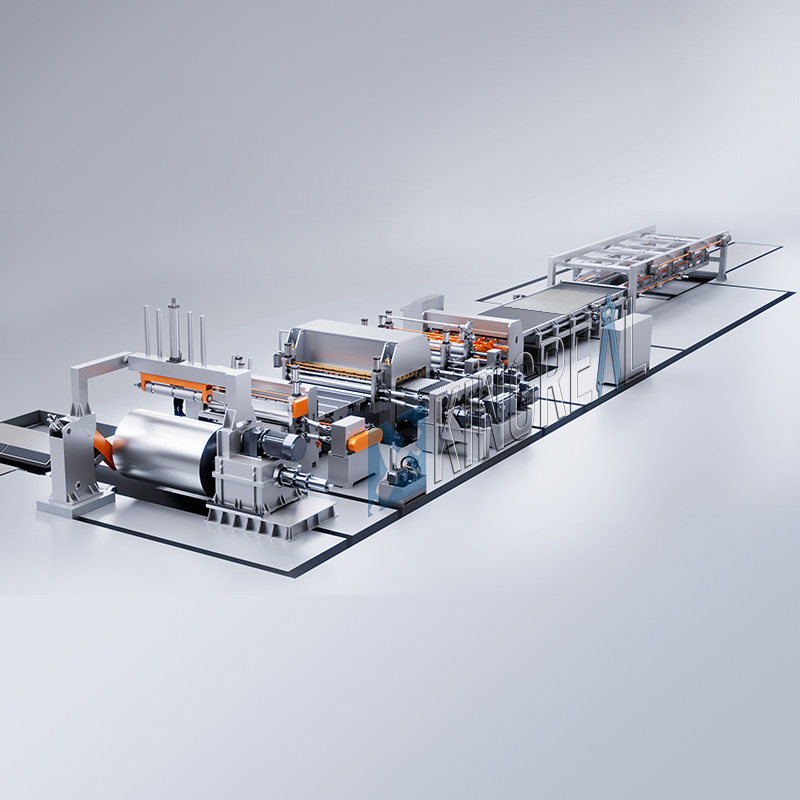

Equipment accuracy plays a crucial role in the production process of sheet metal cut to length machines.

This article will delve into various aspects of sheet metal cut to length lines, including mechanical structure accuracy, electrical control system accuracy, tool quality and maintenance, sheet material handling and positioning, and process parameter optimization, fully revealing the secrets of sheet metal cut to length machine quality.

(1)Mechanical structure accuracy for sheet metal cut to length machine

The mechanical structure of a sheet metal cut to length line is its foundation, and the manufacturing accuracy of each component significantly impacts its overall performance.

For example, if the straightness of the guide rails deviates significantly during machining, the sheet material will shift during transport, resulting in inaccurate cut dimensions.

Furthermore, the pitch accuracy of the lead screw is equally critical, directly determining the accuracy of material feeding. Pitch errors can cause deviations in the cut length, impacting the quality of the final product.

For example, for the thin copper foil required for high-precision electronic components, the guide rail straightness and lead screw pitch accuracy requirements are extremely high. Any slight deviation can result in unqualified copper foil dimensions, thereby affecting the performance of the electronic components.

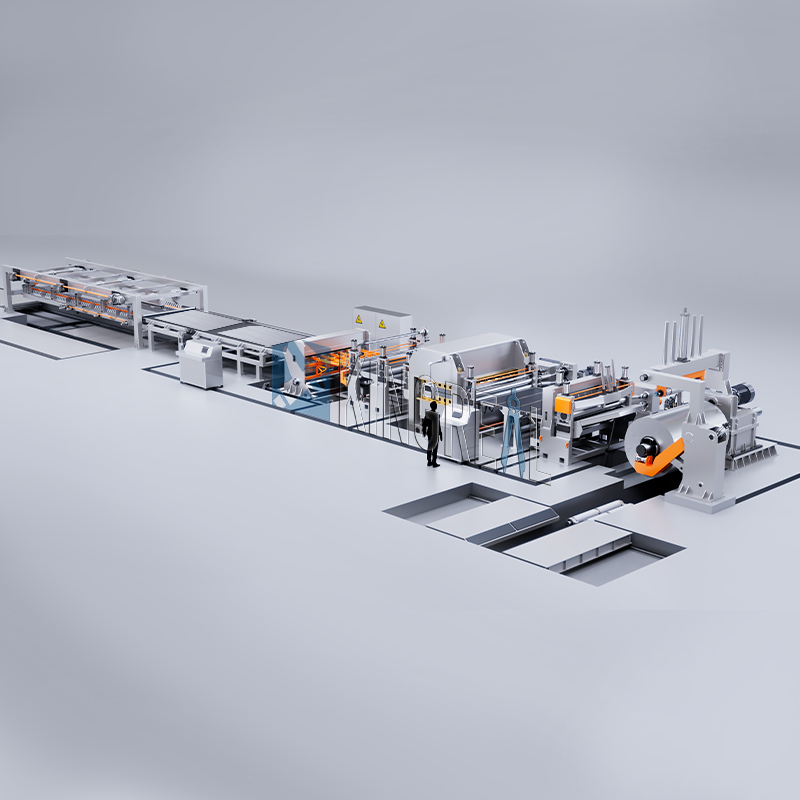

(2)Electrical control system accuracy for sheet metal cut to length machine

The electrical control system of a sheet metal cut to length line regulates the equipment's operating parameters. Its accuracy directly affects the tool feed speed and cutting position.

Accurate servo motor control is very important during automotive parts processing, especially high-strength steel plates.It guarantees component dimensional consistency and satisfies automobile assembly standards by making sure every shear location error remains inside a very narrow range.

Moreover important is the response speed of the control system. Fast and accurate response allows for timely adjustments to sheet metal cut to length machine operating conditions, avoiding quality issues caused by delays.

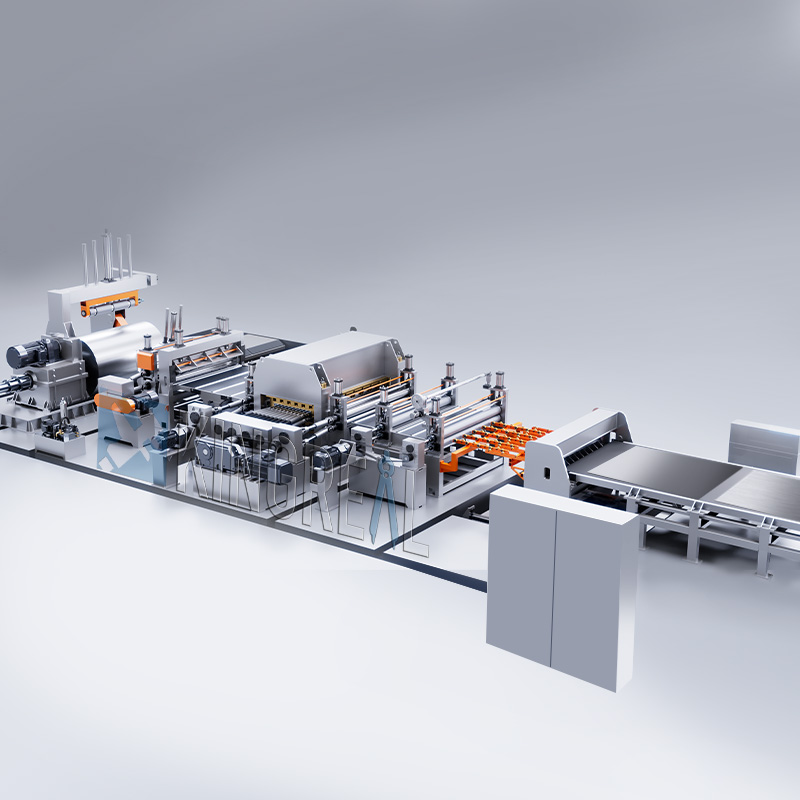

(1)Tool material selection for sheet metal cut to length machine

In sheet metal cut to length lines, tool material selection must be based on the characteristics of the plate being processed.

High-speed steel tools are appropriate for common mild steel plates since they provide great cutting performance and an affordable price. But carbide tools are needed to work tougher plates such as stainless steel and alloy steel.

Their great hardness and wear resistance really lengthen tool life and guarantee cut quality.

Processing titanium alloy plates in the aerospace sector demands even more strict tool material, necessitating the use of specific ultrahard tool materials to withstand the alloy's high strength and toughness.

(2)Tool edge preparation for sheet metal cut to length machine

The quality of the sheared surface is much influenced by the tool's sharp and rugged edge.Sharp and smooth edges of fine-ground cutting tools help to minimize burrs and tears when shearing sheet metal.

High-quality cutting instruments, for instance in processing aluminum sheet metal for architectural decoration, guarantee a smooth, even shear surface, hence lowering the need for follow-up grinding and enhancing product appearance and production efficiency.

Moreover, the cutting tool edge geometry must be adjusted according to the sheet metal thickness and material to guarantee uniform distribution of shear force and hence prevent stress concentration that can cause sheet metal deformation.

(3)Tool maintenance and replacement for sheet metal cut to length machine

Regular tool maintenance and care, such as cleaning and oiling, can effectively prevent rust and increased wear.

Monitoring tool wear and promptly replacing severely worn tools is crucial to ensuring continuous and stable operation of the sheet metal cut to length line. Generally, tool replacement should be considered when cutting edge wear reaches a certain level (e.g., 0.2mm-0.5mm, depending on the tool material and the sheet metal being processed).

Continued use of excessively worn tools can significantly reduce sheet metal shearing quality, leading to dimensional deviations and increased burrs.

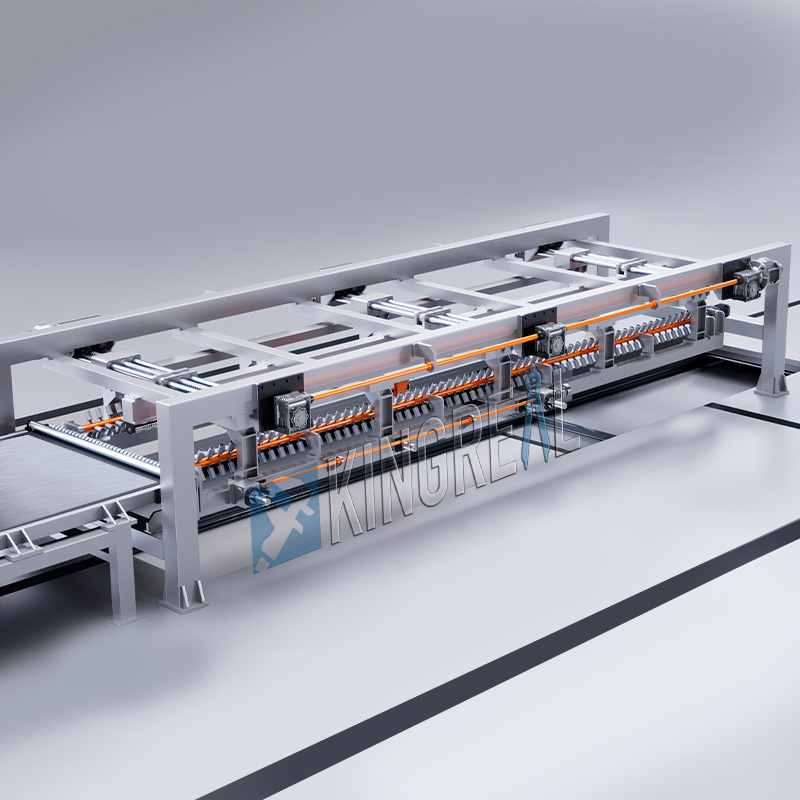

(1)Feeding system stability for sheet metal cut to length line

A stable feeding system is essential for ensuring uniform and accurate sheet feeding into the sheet metal cut to length machine.

The surface roughness and roundness of the feed rollers can affect smooth sheet transport. The sheet will vibrate during transit if the feed rollers are rough or not round enough, causing shear dimension variations.

Moreover, the driving torque stability of the feed motor is important; variations in driving torque can cause erratic feed rates.

For instance, a very stable feeding system is needed when processing galvanized steel sheets for appliance housings to guarantee constant shear dimensions and so preserve assembly precision.

(2)Positioning device accuracy for sheet metal cut to length line

A precise positioning device ensures that the sheet is correctly positioned before shearing. The positioning device's accuracy should be adjusted according to the sheet's processing precision requirements, generally achieving ±0.1mm to ±0.5mm.

Common positioning methods include mechanical positioning and photoelectric positioning. Mechanical positioning offers a simpler structure but relatively low accuracy, while photoelectric positioning offers higher accuracy and faster response speeds.

When processing sheets for precision instrument components, photoelectric positioning devices are often used to effectively ensure accurate sheet positioning and improve product quality.

(1)Shear speed adjustment for sheet metal cut to length machine

The shear speed should be chosen according the thickness and material of the sheet. The shear speed can be raised for thinner sheets in order to raise output efficiency.

For thicker or tougher sheets, though, too fast shear speeds can bend the sheet and raise tool wear.For instance, the shear speed might be adjusted to 30-50 strokes per minute for processing ordinary steel sheets with a thickness of 1mm; for high-strength steel sheets with a thickness of 5mm, the shear speed should be lowered to 10-20 strokes per minute.

(2)Shear gap setting for sheet metal cut to length line

The shear gap refers to the distance between the upper and lower cutting tools. Its size significantly affects the quality of the sheared surface and the life of the cutting tools.

Too small a gap will accelerate tool wear and even damage the tools, while too large a gap will cause burrs and tears on the sheared surface.

Generally, the shear gap should be set to 5%-10% of the sheet thickness (the specific value depends on the sheet material).

When processing aluminum alloy sheets, due to their softness, a smaller value can be used. However, when processing harder steel, a larger shear gap is required.