Steel slitting machines are essential equipment widely used in the steel processing industry.

Steel slitting line’s main purpose is to slice bigger steel coils of different thicknesses, widths, and weights into narrower strips.

Customization of these strips can satisfy particular customer width demands for future production.The quality of the final steel depends on the exactness and speed of the steel slitting line.

Choosing a premium steel slitting machine is therefore vital for raising product quality and production efficiency.

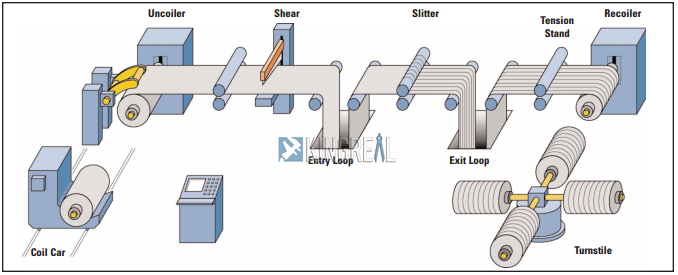

Coil feeding → Decoiling → leveling →Head cutting → Conveying → Guiding →Slitting →Conveying → Tensioning → Recoiling → Output

δb≤450Mpa,

δS≤260Mpa

15pcs (2-3mm)

20pcs(1-2mm)

30pcs(0.3-1mm)

Parameters

Material

Steel ,CR and GI

Tensile strength

Steel thickness

0.2-3.0mm

Steel width

500-1650(Max)

Steel coil I.D

φ480-520 mm

Steel coil O.D

φ1800mm(Max)

Steel coil weight

20T(Max)

Slitter parameters

knife pivot diameter

Ф220 mm

Knife pivot material

40Cr

Blades specification

Φ220mmXφ360mmX20mm

Blade material

6CrW2Si

Slit parameter

Max slit quantity

Width precision

≤±0.05mm/2M

Other parameters

Power

380V/50Hz/3Ph

Line speed

0-120m/min

Capacity

240 Kw

Operator needed

1 mechanical engineer ,2 common workers

(1)Performance Tracking and Analysis

Real-time monitoring and analysis of the performance of the steel slitting machine guarantee top production efficiency.

This real-time monitoring enables the early detection of possible issues and rapid modification of manufacturing settings to preserve effective production.

(2)Improve Production Process

By raising cutting precision and consistency, a steel slitting line can help to improve production processes.By reducing material waste, this great accuracy cutting maximizes coil use.

(3)Automated Cutting Process

By automatically cutting, the steel slitting machine streamlines the operating procedure and lowers the time and labor needed to create small-size steel strip.

The implementation of automation streamlines processes, lowers labor costs, and raises general production efficiency.

(4)Flexible Slitting Width

Steel slitting line can create strips of different widths depending on consumer demands.Manufacturers may better satisfy market needs and create custom goods thanks to this flexibility.

(5)High-Precision Slitting

Large or wide coils of steel plate are slit using extremely sharp blades on steel slitting machines.This guarantees that every strip meets customer requirements by greatly increasing slitting accuracy.

The process of using a steel slitting machine is relatively simple, but some details require attention to ensure safe and efficient operation.

1. Equipment Setup

Make first sure the steel slitting line is properly calibrated.This requires inspecting the steel slitting machine's alignment and the state of the blades. For best cutting, the blades have to remain sharp.

2. Loading the Coil

Load the coil into the steel slitting machine. Carefully secure the coil onto the mandrel.This stage guarantees the coil stays steady during the slitting operation.

3. Parameter Setup

Set the slitting parameters next—speed, tension, and slit width.Various metal materials could call for distinct setups; thus, if necessary, consult the manufacturer's guidelines or get professional advice.

4. Start Slitting

Start the slitting blades once the settings are finished and watch them easily cut across the metal coil. The speed and accuracy of the steel slitting line are remarkable, allowing for effective slitting.

5. Monitor Quality

Monitor the quality of the slitting throughout the slitting procedure. If any issues occur, such as uneven cuts or jagged edges, the slitting parameters may need to be adjusted to ensure the quality of the final product.

6. Unloading the Coils

After the slitting process is complete, carefully remove each coil from the mandrel and inspect it for any defects or flaws. If everything is in good condition, neatly stack the coils for further processing or shipping.

7. Safe Handling

Exercise caution when handling slit coils, as they can be very heavy and sharp. Ensure proper handling equipment is used to avoid accidental injuries from falling heavy objects.

|

|

|

Steel slitting machines are essential equipment in the modern steel processing industry. Their efficient and precise slitting capabilities help manufacturers meet market demands and improve production efficiency and product quality.

Understanding the working process, parameters, and characteristics of steel slitting machines is crucial for their effective use.

Proper operation and maintenance can bring significant economic benefits to businesses, helping them stand out in a fiercely competitive market.