Light gauge cut to length line is to flatten and cut thin metal coils into pre-set lengths. This light gauge cut to length line is widely used in the metal processing industry, particularly for precision cutting of cold-rolled carbon steel, stainless steel, and non-ferrous metals.

This article will provide a detailed analysis of the core structure, process flow, key technical parameters, and core advantages of light gauge cut to length machine, providing readers with a deeper understanding of this highly efficient processing equipment.

A light gauge cut to length machine typically consists of multiple parts that work together to achieve efficient and precise processing. The following are the main components of a light gauge cut to length line:

Loading trolley for light gauge cut to length line: Transports metal coils from the storage area to the decoiler.

Decoiler for light gauge cut to length line: Unwinds the metal coils for subsequent processing.

Pad press for light gauge cut to length line: Ensures the coils remain stable during processing.

Leveling unit for light gauge cut to length line: Levels the coils to eliminate any bending and ensure accuracy during subsequent processing. Six-stage, four-stage, or two-stage leveling units are available, depending on customer needs.

Movable bridge, guide and correction device, and sizing mechanism: Guide and position the coiled sheet, ensuring it remains in the correct position during the shearing process.

Laminating device for light gauge cut to length line: Optional, applies a protective film to the sheet surface.

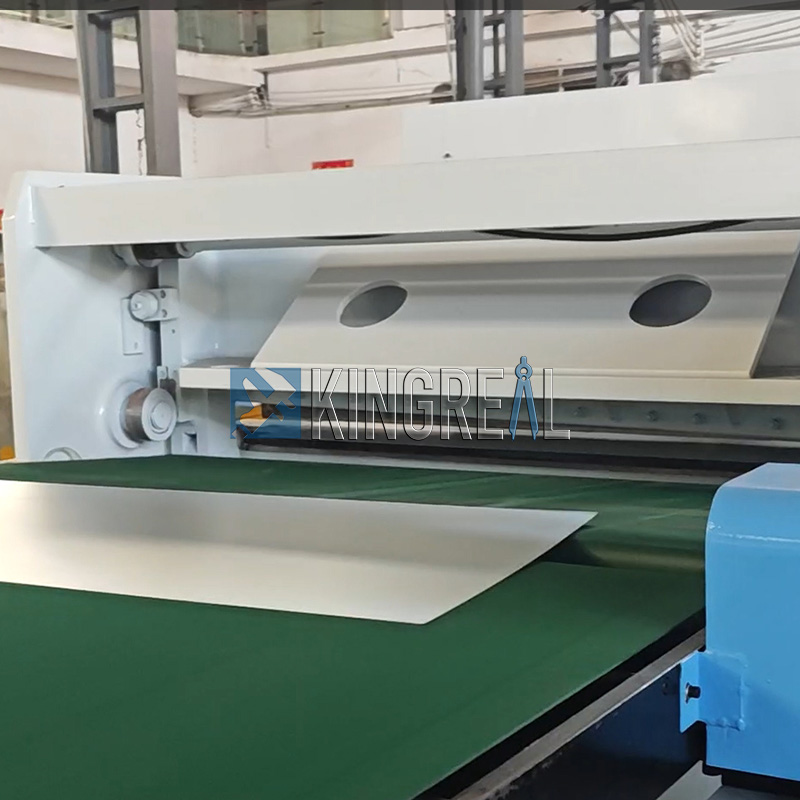

Shearing machine for light gauge cut to length machine:Shears the leveled coiled sheet into sheets of predetermined length. Shearing machines can be either mechanical or hydraulic, adapting to different materials and thicknesses.

Conveyor table for light gauge cut to length machine: Transports the sheared sheets to the next process step.

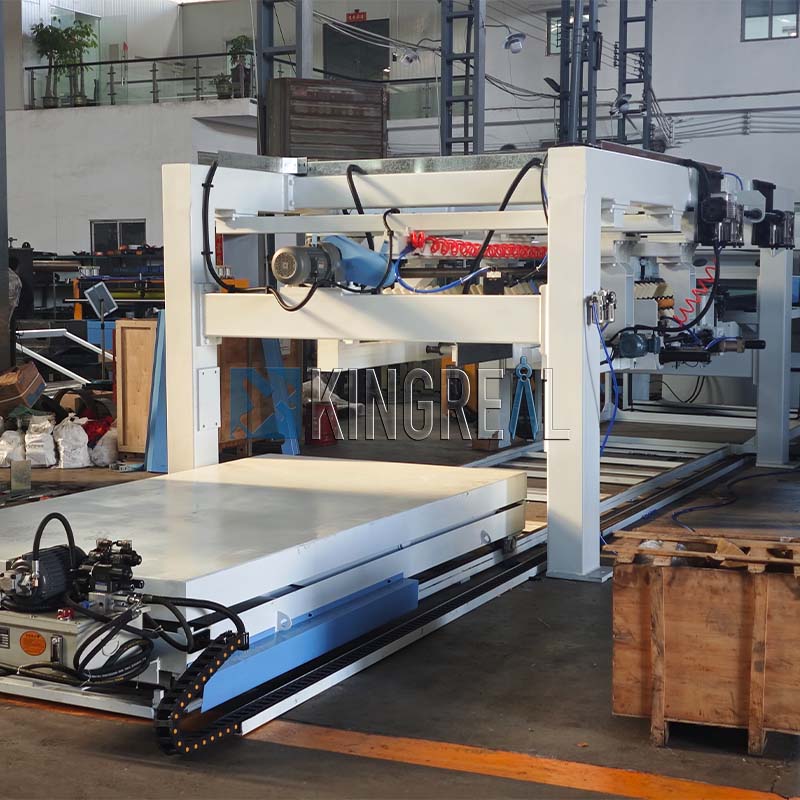

Pneumatic stacking rack, hydraulic lifting platform, and conveyor roller table: These devices automate stacking and transport, improving efficiency.

Hydraulic and electrical control systems:Power and control the entire production line, ensuring coordinated operation of all components.

All components are PLC-controlled, ensuring a high degree of automation and reliability.

|

|

|

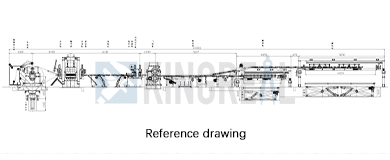

Coil Lifter ---- Decoiler ---- Snubber Roller + Pinch Roll + Pre-Leveling Machine ---- Loop Bridge ---- Side Guide ---- Precision 5-roller Leveling Machine (servo control) ---- High Speed Shear ---- conveyor ---- Auto stacker + X Lifting Platform + Unload Cart

Material

CR, galvanized, color coated steel, stainless steel

Thickness Range

0.2-2mm / 0.3-3.2mm

Width Range

1250/1300/1500/1600/1800/2000mm

Coil Weight

10/15/20T

Coil I.D.

508mm

Cutting Length

500-4000mm; 500-6000mm

Working Speed

0~120m/min (average speed 0~60m/min)

Highly automatic light gauge cut to length line

The light gauge cut to length machine utilizes a PLC system for fully automated control. This system not only coordinates the coordinated operation of various components but also provides real-time monitoring of all production processes. The PLC automatically adjusts equipment parameters based on operating conditions, ensuring optimal operation of the entire light gauge cut to length line. Furthermore, the system supports a rapid parameter reset function, flexibly adapting to changing processing requirements and production conditions, significantly improving the adaptability of the light gauge cut to length machine.

Automatic measurement system for light gauge cut to length line

Equipped with a high-precision automatic measuring device, the system displays the cutting length and production quantity in real time, ensuring that each product meets process standards. Using integrated sensors and a data processing unit, the system completes dimensional inspections in milliseconds and feeds this data back to the PLC control system.

This closed-loop control mode enables the light gauge cut to length machine to dynamically adjust processing parameters based on measured data, ensuring a stable cutting accuracy within ±0.1mm and significantly improving product consistency.

Multiple safety protections for light gauge cut to length line

Equipped with a dual protection mechanism of an emergency stop device and an intelligent alarm system. The safety circuit utilizes the PLC for real-time status monitoring.

If an abnormal signal is detected, the system triggers a protective function within 0.5 seconds, effectively preventing light gauge cut to length machine damage and personal injury.

An audible and visual alarm system simultaneously indicates the fault location, helping operators quickly locate the source of the problem and reducing average fault response time by 40%.

Servo feeding for light gauge cut to length line

A servo-driven feeding system with closed-loop detection technology achieves positioning accuracy of ±0.05mm. The servo motor uses an encoder to provide real-time feedback on the feeding position, dynamically comparing and compensating against the preset value.

Compared to traditional hydraulic feeding methods, the servo system's response speed is 60% faster and supports adaptive adjustment for sudden changes in material thickness, making it ideal for flexible production of high-variety, small-batch production.

Welding heat treatment for light gauge cut to length machine

All steel structure welds undergo stress relief treatment in a large tempering furnace. This process effectively reduces residual welding stress and extends equipment life by over 30%. Untreated welds are prone to fatigue cracking under alternating loads. Tempering at a constant temperature of 580°C ±10°C realigns the metal lattice, maintaining the ideal hardness within the HRC22-26 range, ensuring long-term operational stability.

High-efficiency shearing for light gauge cut to length line

A patented hydraulic system combined with an optimized cutting edge design achieves a high-speed shearing rate of 25 cuts per minute. The special alloy blades have a service life three times that of ordinary materials, and a cut flatness of 0.02mm/m or less. Practical applications have shown that this technology increases single-shift output by 45% while reducing energy consumption by 15%. An optional automatic lubrication system further reduces tool wear.