"A narrow strip coil slitting machine is a machine designed to slit wide webs into narrow rolls. It is widely used in manufacturing, trade, and service centers across a variety of industries, including electronics, electrical appliances, communications, automotive, audio, and daily chemicals. This article will provide a detailed introduction to narrow strip coil slitting lines."

The operating principle of a narrow strip coil slitting line generally involves three main steps: feeding, slitting, and rewinding. The material is fed into the slitting area via a feeder, slit by precision cutting blades, and then rewound into a narrow roll by a recoiler. During the slitting process, the narrow strip coil slitting machine utilizes tension control and a web-correcting device to ensure slitting accuracy and stability.

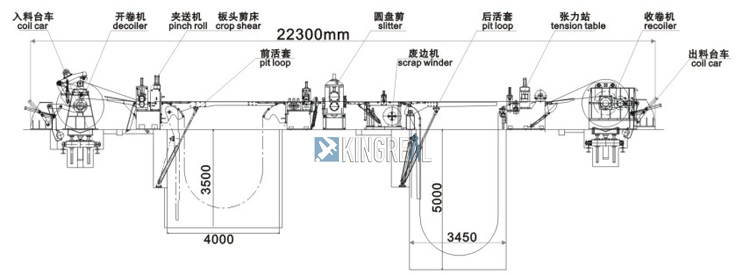

Trolley for coil loading → Hydraulic decoiler →2 rolls feeding and 3 rolls leveling → Loop bridge → High precision shearing machine → Side scrap recoiling →Pre-seperator and damping tension machine → Rewinding

Input Thickness Max*

0.10mm – 6.00mm

Input Width Max*

100mm ̴ 500mm

Coil Weight Max*

2,500kgs(1.5tons)

Mill speed Max*

80MPM

No. of Slit

as per customer requirement

Maximum inner/outer diameter of the coil

300mm – 350mm – 508mm /1500mm

Minimum Slit Size

5 mm

Depression type

Mechanical Screw Down

Roll bearing lubrication method

Grease lubrication

Line Speed

40 mpm

Electronic control

Siemens

Driven

Backup roll Driven

Motor

Siemens / Bharat Bijlee

Total installed capacity

30 kw – 150 kw

Unit size

20m×6m×2m

(Narrow strip coil slitting machine specifications are for reference only. KINGREAL STEEL SLITTER specializes in providing customized narrow strip coil slitting line solutions. Please contact KINGREAL STEEL SLITTER if you have special requirements.)

1. Efficient and high-speed narrow strip coil slitting line

The narrow strip coil slitting machine utilizes advanced control systems and slitting technology, enabling high-speed and high-precision slitting on the narrow strip coil slitting line. This efficient operation significantly improves production efficiency. The narrow strip coil slitting machine's efficiency is reflected not only in slitting speed but also in its stability and continuity during the slitting process, enabling 24-hour uninterrupted operation and significantly increasing overall production capacity.

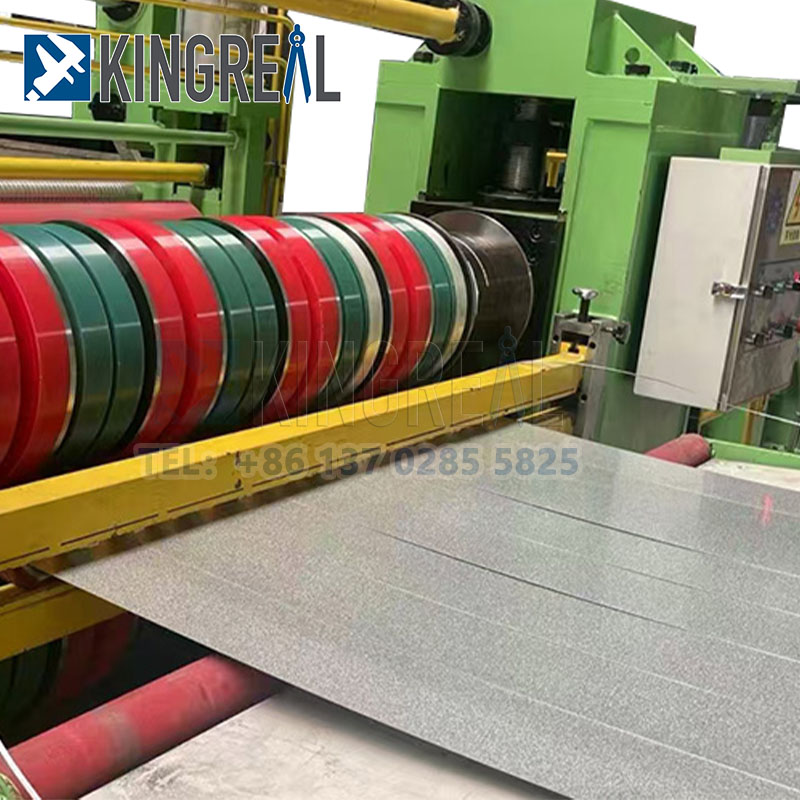

2. Precision slitting for narrow strip coil slitting line

High precision slitting tools and sophisticated deflection correction mechanisms on the narrow strip coil slitting machine guarantee the best possible degree of slitting precision.For many sectors, this is essential as consumer demands often include strict dimensional standards and accuracy demands. Accurate slitting helps to lower material waste and increase product yield whether in building materials, metal processing, or electronic parts.Moreover, the narrow strip coil slitting machine provides great stability throughout the slitting process, therefore guaranteeing uniform slitting results over coils of several materials and thicknesses, hence guaranteeing consistent quality across every batch.

3. Highly automated narrow strip coil slitting machine

Usually fitted with a highly computerized control system allowing fully automated feeding, slitting, and rewinding processes, contemporary narrow strip coil slitting lines are usually This growing automation helps to minimize mistakes and instability brought on by human action in addition to greatly lowering labor costs.The operator only has to undertake basic settings and monitoring; the equipment automatically runs under prearranged conditions.

4. Widely applicable narrow strip coil slitting machine

Narrow strip coil slitting lines are suitable for a broad spectrum of applications, handling narrow width coils of a range of metal materials including stainless steel, steel, aluminum, iron, copper, and PPGI. This flexibility lets them be extensively used in a number of sectors, including electronics, home appliances, building, and car production. Whether you need complex slitting requirements for different materials or strict requirements for specific dimensions, narrow strip coil slitting machines can handle them.

1.High-strength reinforced frame for narrow strip coil slitting machine

With window sizes limited to within 0.04 mm, the narrow strip coil slitting line's high-strength reinforced frame guarantees great stability during processing and so accuracy to the narrowest tolerances.

This accuracy provides unmatched benefits by guaranteeing product quality and satisfying the needs of premium markets, especially in precision-critical sectors like aerospace and electronics.

2.High-hardness rollers for narrow strip coil slitting machine

Forged alloy steel with a hardness of 62+ HRC makes up all rollers, hence guaranteeing wear resistance throughout prolonged usage.This high-hardness material not only raises slitting performance but also increases the lifespan of the gear and lowers maintenance expenses.

3.Spherical roller bearings for narrow strip coil slitting line

All rollers use C45 grade cast steel housing spherical roller bearings.This arrangement ensures smooth running and longevity by great friction reduction.Spherical roller bearings guarantee flawless performance even under heavy loads, hence guaranteeing a smooth cutting process.

4.Electric worm gear reducer for narrow strip coil slitting machine

The narrow strip coil slitting line is equipped with an electric worm gear reducer, combined with a bronze nut and serrated alloy steel screws, ensuring efficient and stable power transmission. This combination effectively reduces energy consumption while improving cutting accuracy and stability.

5.Extra-heavy-duty gearbox for narrow strip coil slitting machine

The ultra-heavy-duty gearbox and pinion housing ensure reliability in the face of demanding applications. The hardened output shaft enhances its load-bearing capacity, ensuring the narrow strip coil slitting line maintains efficient operation over extended periods of operation.

6.Roller removal cart system for narrow strip coil slitting machine

The roller removal cart system facilitates roller replacement and improves maintenance efficiency. Operators can quickly and safely change rollers, reducing downtime and ensuring efficient narrow strip coil slitting line operation.

-Automotive Parts

-Home Appliances

-Building Materials

1.Speed, precision, and reliability

The speed of KINGREAL STEEL SLITTER narrow strip coil slitting machines is well known; it lets producers satisfy strict deadlines without sacrificing quality.One major benefit of KINGREAL STEEL SLITTER narrow strip coil slitting lines is accuracy, which guarantees that every slit coil is uniform and satisfies demanding industry requirements.

2.Fully automated narrow strip coil slitting machines

A key feature of KINGREAL STEEL SLITTER narrow strip coil slitting lines is their fully automated operation from decoiler to recoiler. The fully automated narrow strip coil slitting machine allows the operator to automatically feed the strip into the recoiler clamps without touching the material. This makes the process safer and more efficient, reducing the risk of injury and increasing productivity.

3.High safety standards and machine guarding

KINGREAL STEEL SLITTER narrow strip coil slitting lines are designed to the highest safety standards, including comprehensive safety systems, full perimeter guarding, and a safety PLC (Programmable Logic Controller). These features minimize the need for personnel to be near moving parts, reducing the risk of accidents and improving overall workplace safety.

4.Extensive machine manufacturing experience

KINGREAL STEEL SLITTER has over two decades of experience in narrow strip coil slitting machine manufacturing and offers customers a quality guarantee and first-class customer service and support, ensuring that any narrow strip coil slitting line issues are promptly resolved, ensuring smooth production line operation.

1. Operating Instructions: Operators must be familiar with the narrow strip coil slitting line's operating procedures, correctly install the cutting tool, and adjust the cutting speed and thickness. During operation, pay attention to safety to avoid accidents.

2. Maintenance: Regularly clean and maintain the narrow strip coil slitting machine, inspect the cutting tool for damage or wear, and replace it promptly. Also, check the narrow strip coil slitting line's transmission and electrical components for proper function to ensure long-term, stable operation.