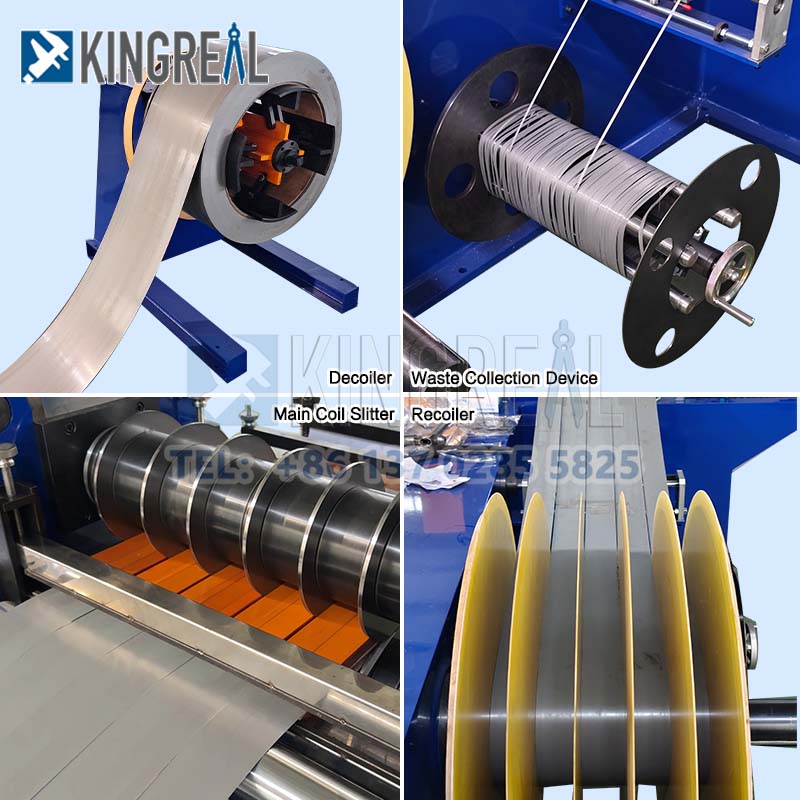

KINGREAL STEEL SLITTER offers a simple coil slitting machine for customers with a lower budget. This simple coil slitting line is primarily used to slit wide coils into narrow strips tailored to the customer's needs and then rewind them to the production line.

This simple coil slitting machine is designed to meet the needs of customers with lower precision and coil width requirements. KINGREAL STEEL SLITTER also offers a simplified version of the simple coil slitting line. This simple coil slitting machine minimizes equipment requirements while still meeting the needs of a simple coil slitting line.

Both the simple coil slitting machine and the standard metal slitting machine can process a variety of metal materials, including cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and coated materials, etc, providing precise slitting and automatic operation.

Loading coil → decoiling → pinching → shearing → looping → guiding → slitting → rewinding scrap → looping → tension → recoiling → unloading coils

Model

Material Thickness(mm)

Material Width(mm)

Number of Strips

Speed

Coil Weight

Remark

Model 1

0.1-1

80-350

8-30

50-100

3

Technical parameters and equipment configuration can be determined according to customer needs

Model 2

0.2-2

80-350

6-30

50-150

3

Model 3

0.2-2

80-450

6-30

50-150

5

Model 4

0.2-2

80-650

6-30

50-150

7

Model 5

0.2-2

80-800

6-30

50-150

7

Model 6

0.1-1

500-1300

12-30

50-200

7/15

Model 7

0.3-2

500-1600

12-30

50-200

7/15

Model 8

0.3-3

500-1600

8-30

50-180

15

Model 9

0.3-3

900-1800

8-30

50-180

20

Model 10

1-4

900-1600

6-30

50-120

20

Model 11

1-6

900-1600

6-30

30-80

30

Model 12

2-12

900-1600

5-30

20-50

30

a. Hydraulic coil loading trolley for simple coil slitting machine

1. Main Components: Welded steel structure, moving wheels, four guide columns, drive shaft, etc.

2. Maximum load: 10 tons, 1.1 kW cycloidal pinwheel motor, travel speed 6 m/min.

3. Hydraulic Drive: Can lift coils under 10 tons up and down, with a maximum stroke of 500 mm. Hydraulic cylinder: FA-Φ125 mm (one set).

b. Hydraulic decoiler for simple coil slitting line

1) Main Components: Welded steel structure, four arched blades, wedge-shaped sliding base, mandrel, side plates, bearings, bearing seat, pneumatic disc brake, etc.

2) Expansion and Retraction Range: Φ460 mm to Φ520 mm × 850 mm.

3) Maximum Load: 10 tons.

4) Hydraulic Drive: Expansion and Retraction are performed by push-pull hydraulic cylinders; Hydraulic Cylinders: FA-Φ200 mm (1 set)

5) Motor Power: 4.0 kW cycloidal pinwheel motor + inverter, chain-driven feed

6) Press Roller: 1.1 kW cycloidal pinwheel motor

c. Hydraulic support arm for simple coil slitting machine

Purpose: Supports the main decoiler arm and increases the reel's rotational inertia.

Single-arm structure, hydraulic cylinder lifts and lowers.

During unwinding, the support arm rises to support the decoiler arm; during loading, the support arm descends.

d. Peeler, press roller, hydraulic shear for simple coil slitting line

Main Structure: Welded Steel Plate

Press Roller: φ250×1050mm, seamless tube, polyurethane rubber coating, 18.5kW conventional motor with variable frequency drive

Hydraulic Shear: Welded Steel Plate Frame, Cast Steel Blade Base

Cutter: Four-sided blade, material: Cr12MoV, hardness: 60±1

Hydraulic Drive: Hydraulic Cylinder: FA-φ100mm, 2 sets

e. Looping pit and bridge for simple coil slitting machine

Main Structure: Welded Steel Plate

Hydraulic Drive: CA-φ80mm, 1 set of hydraulic cylinders controls bridge raising and lowering

f. Manual side guides for simple coil slitting line

1. Main Components: Steel Plate, Press Roller Assembly, Polyurethane Rubber Wheel, Screw Handwheel, Electric Adjustment, etc.

2. Side Guide Rollers: Material: Cr12MoV, high-temperature quenched and tempered, HRC 580-620, 2 rollers on each side

g. Slitting machine for simple coil slitting line

1. Main Components: Steel plate structure, cast base, synchronous gearbox, lifting mechanism, clutch coupling, universal joint, etc.

2. Cutter Shaft: 40Cr, φ140 x 1050mm, T-slot 28mm, medium-frequency quenching and tempering, ground, hard chromium treated, slot depth 16mm.

3. Cutter Outer Diameter: φ280mm (Buyer Provided)

4. Fixing Method: Cutter Locking with Nuts

5. One Adjustment Bracket Set for Fixing the Wood Strips

6. Side Panels Move Electric, Cutter Shaft Lift and Lower Electric Synchronously

7. Slitting Motor: 45kW AC Motor + Inverter

h. Separate scrap winder for simple coil slitting machine

Main Components: Welded Steel Plate Structure, Guide Rollers

Double-Sided Scrap Winder, Telescopic Mechanism, Automatic Discharge, AC Motor + Inverter Drive

i. Looping pit and bridge for simple coil slitting line

Main Frame: Welded Steel Plate Structure

Hydraulic Drive: Hydraulic Cylinder Controls Bridge Lift and Lower: CA-Φ80mm (1 Set)

j. Plate tensioning station for simple coil slitting machine

Main Structure: Steel Plate, Separating Roller, PU Rubber

Tensioning Pad: Wool-Coated

Roller: Φ500mm, PU Rubber-Coated

Hydraulic Drive: Controls the raising and lowering of the plate; Hydraulic Cylinder: FA-Φ100mm (2 sets)

k. Hydraulic coiler, hydraulic ejector for simple coil slitting line

Main Components: Welded Steel Structure, Four Steel Plates, Wedge-Shaped Sliding Base, Mandrel, Side Plates, Bearings, Bearing Blocks, Push-Pull Hydraulic Cylinder, Gearbox Reducer, Hydraulic Ejector, Pneumatic Brake, etc.

Unrolling Diameter Range: Φ480mm to Φ508mm × 850mm

Push-Pull Hydraulic Cylinder: FA-Φ150mm

Maximum Load Capacity: 10 tons

75kW AC Motor + Inverter

Ø80mm Press Arm, Hydraulically Liftable

l. Hydraulic support arm for simple coil slitting machine

Purpose: Supports the main coiler arm and increases the coiler's rotational inertia.

Single-arm structure, hydraulically liftable

During coiling, the support arm lifts upward to support the coiler arm; during unloading, the support arm lifts downward.

m. Hydraulic unloading cart for simple coil slitting line

1) Main Components: Welded steel structure, travel wheels, four guide columns, drive shaft, etc.

2) Maximum Load Capacity: 10 tons, 1.1kW cycloidal pinwheel motor, travel speed: 6 m/min.

3) Hydraulic Drive: Capable of lifting coils up to 10 tons, with a maximum stroke of 500 mm. Hydraulic Cylinder: FA-Φ125mm, one set.

n.Hydraulic system for simple coil slitting machine

Main Components: 300 kg welded steel plate oil tank, various hydraulic valves, and oil circuit boards.

Hydraulic Drive Power: E-class 11 kW motor, 30 ml displacement, normal pressure: 70 kg/cm², maximum pressure: 140 kg/cm².

o. Electrical control system for simple coil slitting line

1) One main control console and two auxiliary control cabinets facilitate coil loading and unloading.

2) Power Supply: Three-phase 380V ±10%, 50Hz ±1Hz

3) Main Components and Applications: The entire line consists of a main control console, an auxiliary control console for the decoiler, an auxiliary control console for the recoiler, and an electrical control cabinet. The entire simple coil slitting line utilizes centralized control. The main control console features digital display, high and low speed adjustment, manual feeding, continuous slitting, and fault alarm functions. All components are imported or from well-known domestic brands. A touchscreen control system facilitates the setting and adjustment of speed and other parameters. It can easily switch between manual, stand-alone and automatic modes, and can monitor the working status of each component at any time to ensure safe and efficient operation of the entire simple coil slitting line.

|

|

|