Steel Coil Packaging Machine (Coil Package Machine)is a new type of winding and packaging equipment mainly designed and manufactured for metallurgical industry, which is widely used for winding and packaging of copper belt, steel belt, steel coil, aluminum belt, and other ring-shaped objects.

KINGREAL STEEL SLITTER can supply the Coil Packaging Machine, which is a new type of winding and packaging equipment mainly designed and manufactured for metallurgical industry, which is widely used for winding and packaging of copper belt, steel belt, steel coil, aluminum belt, and other ring-shaped objects. After winding packaging, not only the appearance of the coil is beautiful and generous, but also has a good moisture-proof, dust-proof, rust-proof, anti-aging, anti-accidental damage and other functions.

|

1. Feeding robot; 2. Pre out-feeding device; 3. circumferential labeling device. |

|

Width of metal strip |

50~300mm |

|

Outer diameter of metal strip |

500~1000mm |

|

Inner diameter of metal belt |

300~500mm |

|

Composite paper belt width |

70~90mm |

|

Maximum outer diameter |

600mm |

|

Roller line speed |

6m/min (variable frequency adjustable) |

|

Ring body speed |

60~80r/min (adjustable by frequency conversion) |

|

Roller height |

770mm |

|

Roller load |

2500kg |

|

Overlapping range |

30%~70% (arbitrary overlapping) |

|

Total power |

4kW |

|

Power source |

380V, three-phase four-wire |

|

Weight about |

1000kg |

1. Horizontal structure, the product through the lifting, conveying or manual way of packaging bit can be used according to the needs of the internal or external wear structure - using PLC programmable controller and man-machine dialogue touch screen

2. Automatic alarm, automatic display of fault content.

3. Slip ring automatic positioning

4. Adopt taper roller drive, outer guard rollers to protect the lighter products with upper pressure rollers.

5.Adjust the heavy and tightness of packing belt according to the need.

6. Slip ring can be moved back and forth to adapt to different inner diameter and outer diameter of the product - the use of high wear-resistant polyurethane friction wheels, slip ring for the whole casting structure.

7. Synchronized winding mechanism is optional, which can complete the synchronized winding of two different packaging materials at the same time.

8. The rollers and guard rollers are covered with polyurethane.

1. Types of packing machines

Choose the appropriate type of wrapping machine according to the shape and size of the coil.

Horizontal Packing Machine: For horizontal coils, the coil rotates on the horizontal plane.

Vertical wrapping machine: Suitable for vertically placed coils, the coils rotate in the vertical plane during wrapping.

2. Adaptation to the size and weight of the coils

Ensure that the wrapping machine is capable of handling all sizes of coils in production, including maximum and minimum diameters, widths, and weights. The equipment should have sufficient load capacity and adjustability.

3. Degree of automation

A highly automated packaging machine reduces manual intervention, improves efficiency, and reduces human error. Automation features include automatic feeding, automatic packaging, automatic labeling, automatic packing, etc.

4. Control system

Modern packaging machines are usually equipped with a PLC control system that provides an intuitive operator interface and parameter setting functions. Reliability and ease of use of the control system are important considerations in the selection.

5. Safety

The packaging machine should comply with safety standards and be equipped with necessary safety devices, such as emergency stop button, safety guardrail, etc., to protect the safety of operators.

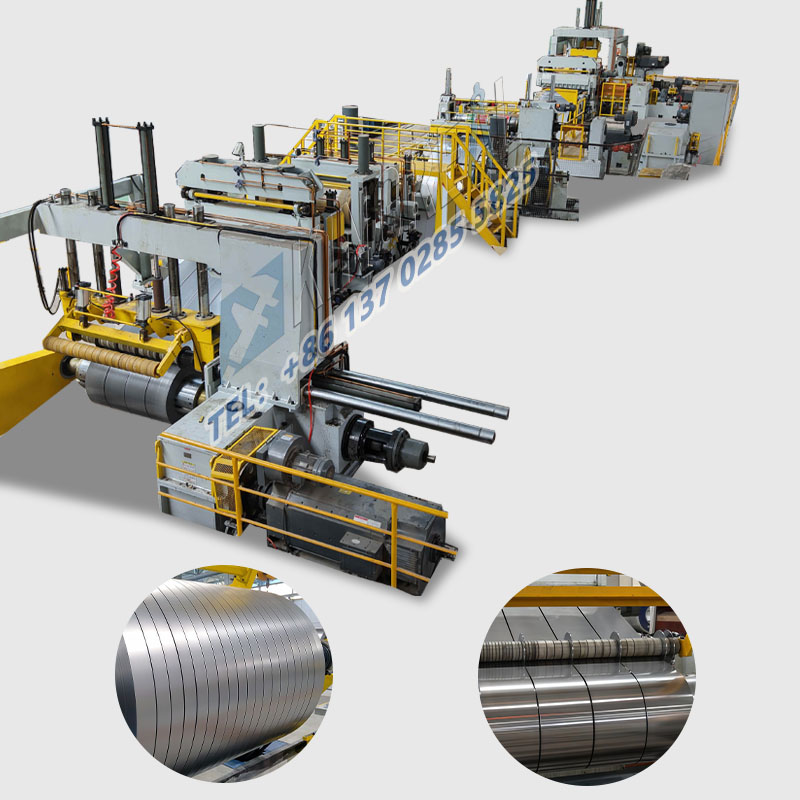

Metal slitting machine is one of the common coil processing equipment, which is used to slit metal coils of different material thicknesses into specified widths and numbers of strips according to customers' needs and finally wound up. The final slitting coil usually needs to enter the next step of processing and use, which for the slitting coil packing and packaging requirements are relatively high, most factories will choose to buy automatic packaging machine.