KINGREAL STEEL SLITTER is a professional manufacturer of coil processing equipment, committed to providing customers with efficient and reliable solutions. KINGREAL STEEL SLITTER team provides comprehensive pre-sales, sales, and after-sales support, ensuring customers receive timely support and professional service.

1. KINGREAL STEEL SLITTER Professional Team

KINGREAL STEEL SLITTER various departments work collaboratively to provide customers with the highest quality service. KINGREAL STEEL SLITTER sales team, with extensive industry experience, is able to quickly respond to customer needs and provide targeted product recommendations and solutions. KINGREAL STEEL SLITTER customer service team is dedicated to answering all customer questions and ensuring a positive customer experience. Furthermore, KINGREAL STEEL SLITTER manufacturing and engineering teams strive for technical excellence, focusing on every detail of their products to ensure efficient operation.

2. KINGREAL STEEL SLITTER Manufacturing Workshop

KINGREAL STEEL SLITTER fully equipped manufacturing workshop is divided into multiple areas: sheet metal processing, CNC machining, raw material processing, assembly, and welding. Each workshop is equipped with high-precision production equipment to ensure that every machine produced meets stringent quality standards.

3. KINGREAL Steel Slitter After-Sales Service

KINGREAL Steel Slitter has a comprehensive after-sales service for customers, covering both online and offline channels, ensuring customers receive comprehensive support throughout the coil processing line lifecycle. KINGREAL Steel Slitter offers a variety of services, including machine troubleshooting, installation, operator training, and maintenance, striving to provide customers with efficient solutions.

4. KINGREAL STEEL SLITTER Extensive Project Experience

KINGREAL STEEL SLITTER boasts over 20 years of industry experience, integrating design, R&D, sales, and manufacturing. KINGREAL STEEL SLITTER has provided high-quality equipment and services to customers in numerous countries and regions around the world. KINGREAL STEEL SLITTER coil processing equipment has been successfully exported to countries such as the United States, Indonesia, Morocco, Mexico, Italy, and Brazil, earning widespread acclaim. During project execution, KINGREAL STEEL SLITTER engineers are able to design customized machine manufacturing solutions based on the customer's exact production needs. Furthermore, the KINGREAL STEEL SLITTER team continuously monitors global market trends and promptly adjusts product strategies to maintain a competitive advantage.

|

|

|

KINGREAL STEEL SLITTER product line encompasses metal slitting machines, metal cut to length lines, and perforated metal machines, meeting the diverse production needs of our customers.

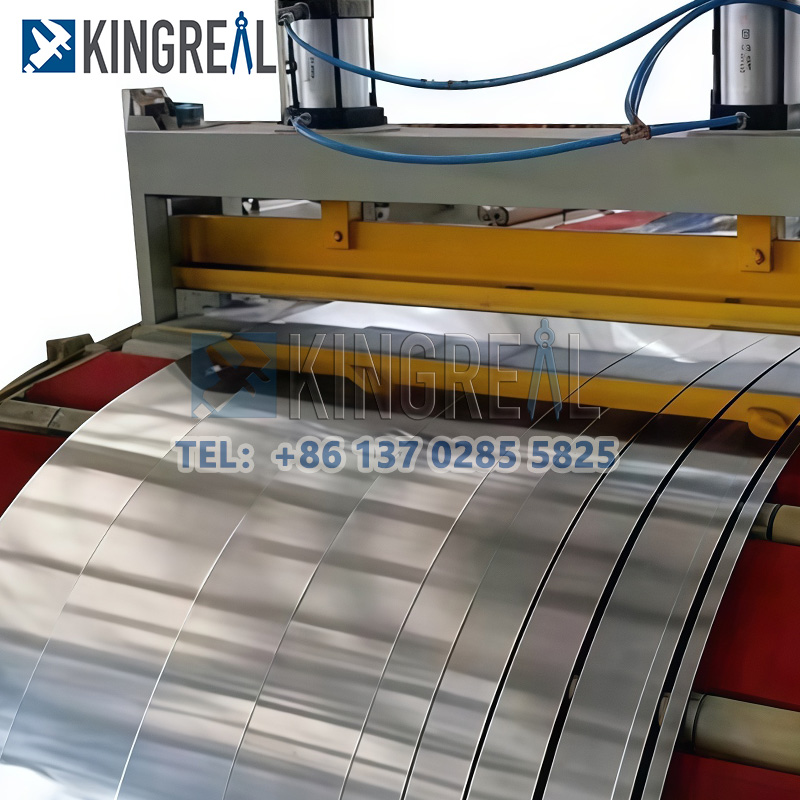

1. Metal Coil Slitting Machines

Metal coil slitting machines are used to precisely slit thick metal coils and reel narrower strips. KINGREAL STEEL SLITTER offers a variety of metal coil slitting machine types, including:

Light duty slitting machines: Suitable for thicker metal coils, ensuring efficient slitting and recoiling.

Heavy duty slitting machines: Designed specifically for thin metal coils, maintaining material integrity and precision.

High speed slitting machines: Featuring high speed and efficiency, suitable for large-scale production.

Dual slitter head coil slitting machines: Equipped with dual blades for improved production efficiency.

Belt tension coil slitting machines: Adjustable belt tension ensures material stability during the slitting process.

Silicon steel slitting machines: Specifically designed for silicon steel coils, meeting the processing needs of specialized materials.

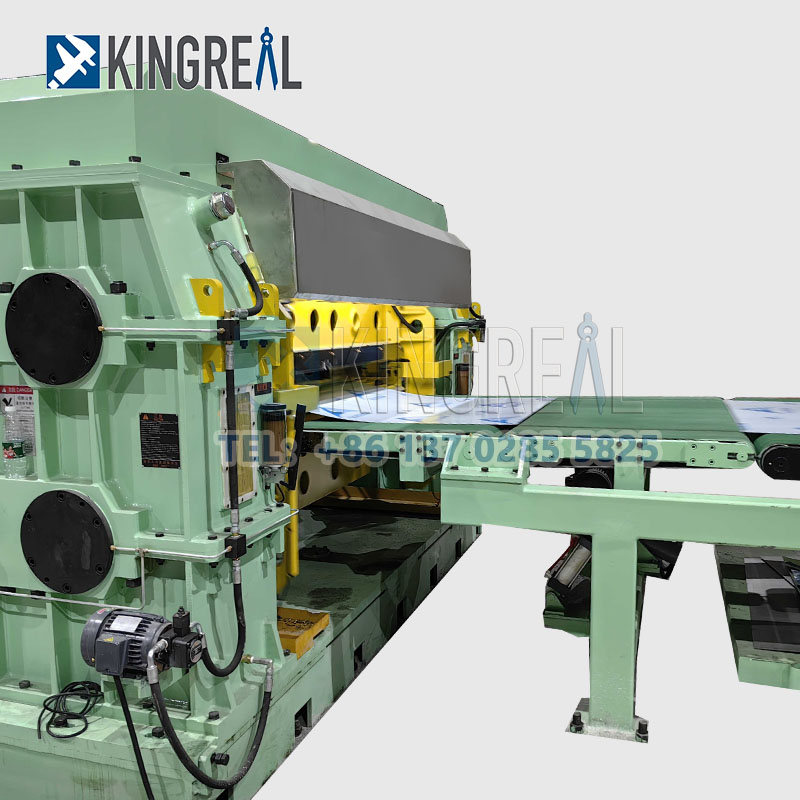

Metal cut to length lines are used to cut coils of various materials horizontally into customer-defined lengths. KINGREAL STEEL SLITTER offers customized metal cut to length line solutions based on material thickness, width, and weight, including:

Fly shearing cut to length lines: Suitable for rapid shearing, widely used in large-scale production. Rotary shearing cut to length line: Utilizes a rotating blade to ensure precise and efficient cutting.

Swing shearing cut to length line: Highly flexible, capable of cutting metal materials into various shapes.

Fixed shearing cut to length line: Shearing requires downtime, resulting in slower production speeds.

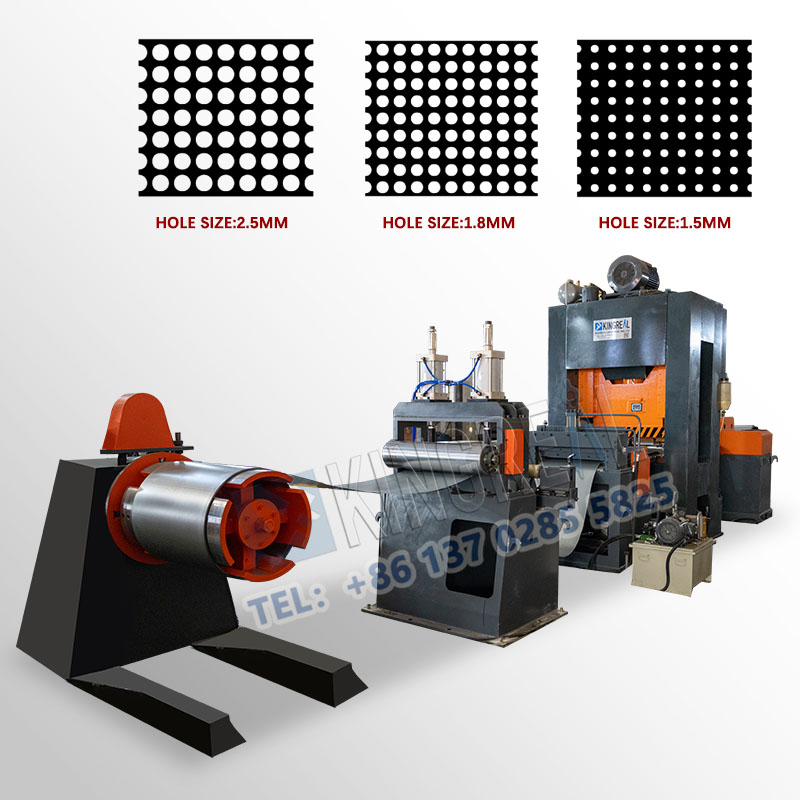

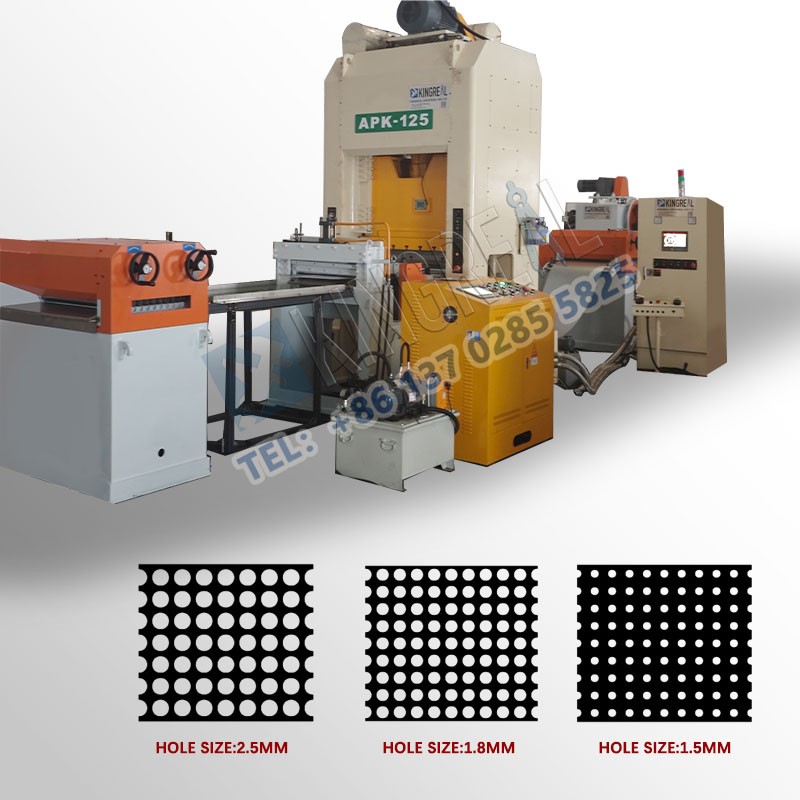

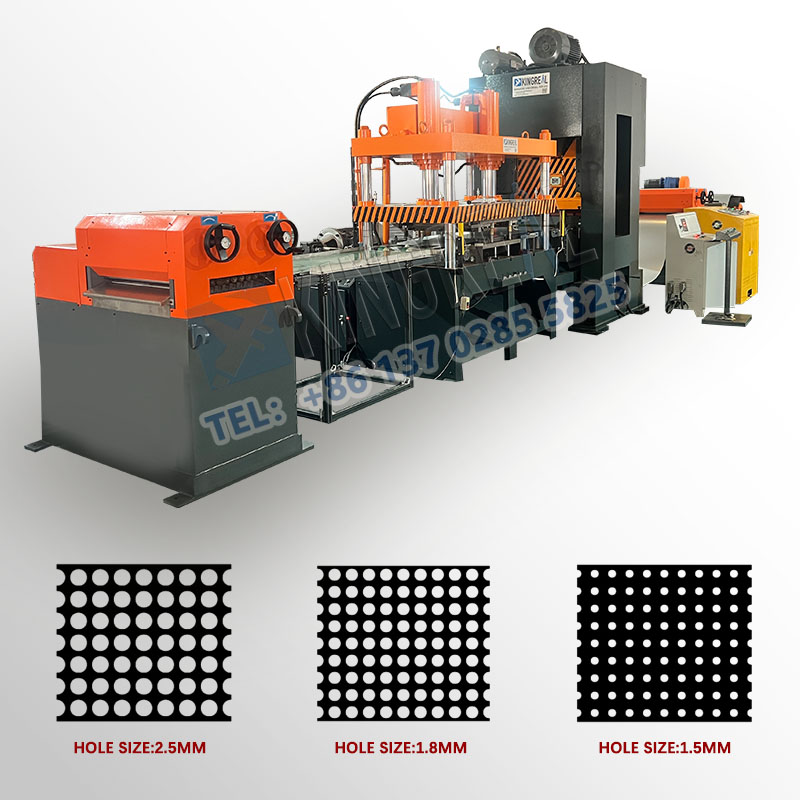

Perforated metal machines can punch holes in various metal coils, with hole shapes and diameters customizable according to customer drawings. KINGREAL STEEL SLITTER featured perforated metal machines include:

Coil to coil perforation line: Rewinds the material after punching, saving space and time.

Sheet metal perforation machine: Combines punching and shearing functions, facilitating subsequent processing and manufacturing.

Metal ceiling tile perforation line: Specializes in producing perforated ceiling panels of various sizes to meet the needs of the construction industry.

If you want to know more information about KINGREAL STEEL SLITTER machines (metal slitting machine, metal cut to length machine, perforated metal machine,etc ), welcome to consult KINGREAL STEEL SLITTER!

KINGREAL STEEL SLITTER can provide Thick Plate Slitting Machines suitable for steel coils of different specifications. This heavy duty slitting machine can process coils with a thickness of 6-16mm and produce high-precision narrow strips for use in industries such as shipbuilding, construction, and metal processing.

Professional manufacturer and supplier KINGREAL MACHINERY provides complete solutions in coil processing manufacturing lines, including stainless steel slitting equipment. We can offer (1-8)X1500mm Stainless Steel Coil Slitting Machine for various materials. We have established partnerships with clients all across the world since 1995.

1300MM Dual Slitter Head Coil Slitting Machine,steel coil slitting line is one of KINGREAL STEEL SLITTER most distinctive coil processing equipment. The dual slitter head design is suitable for 0.3-3MM coils to achieve high speed coil slitting production efficiency of 220M/Min. High speed steel slitting line is currently sold to Turkey, Russia, Saudi Arabia and other countries.

KINGREAL Cut To Length Line Machine With Dual Stacker used to leveler, shearing and stacker the different coil. Cut To Length Line can shearing the different size plate and auto stacker according to the customer need.

KINGREAL STEEL SLITTER Sheet Metal Cut to Length Machine is usually used to decoiler, leveler and cut coils of different materials and thicknesses to the widths specified by customers. Common coil thicknesses range from 0.3-3mm, with different production designs for different raw materials and production requirements. Please feel free to send your request to KINGREAL STEEL SLITTER!

KINGREAL STEEL SLITTER 850MM Steel Coil Slitting Machine is specifically designed for 850mm wide metal coils, efficiently and accurately producing narrow strips with high precision. KINGREAL STEEL SLITTER is committed to providing customers with complete steel coil slitting machine production solutions.