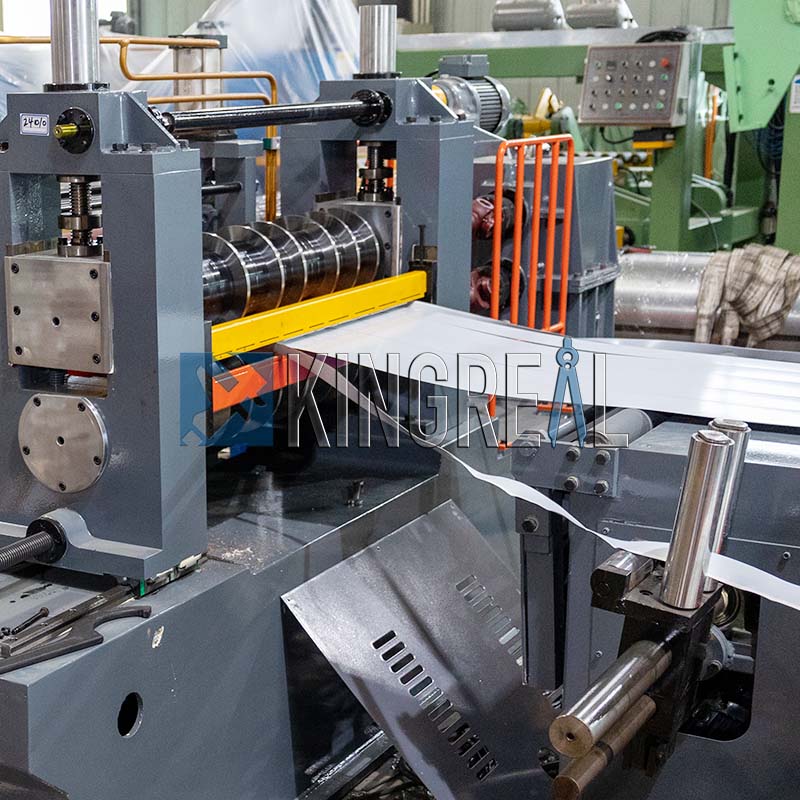

KINGREAL STEEL SLITTER 850MM Steel Coil Slitting Machine is specifically designed for 850mm wide metal coils, efficiently and accurately producing narrow strips with high precision. KINGREAL STEEL SLITTER is committed to providing customers with complete steel coil slitting machine production solutions.

850MM Steel Coil Slitting Machines are designed for precision slitting of coils of different materials to specified widths according to customer's production requirements and for final winding into coils. The finished metal slitting coils are widely used in the transformer manufacturing, motor manufacturing, pipe welding, automotive manufacturing and cold forming industries. It is often further processed for production use.

Depending on the thickness of the coil, the metal slitting line machine can be divided into heavy duty slitting machines for thick plates, medium duty slitting machines for medium plates, and light duty slitting machines.

According to the different production requirements can be divided into high-precision coil slitting machine, dual slitter head coil slitting machine and belt tension coil slitting machine.

KINGREAL STEEL SLITTER has more than 20 years of experience in manufacturing and selling metal slitting machines for large-scale production lines, and is able to provide diversified solutions according to customers' production needs. Please feel free to contact us!

KINGREAL STEEL SLITTER 850MM Steel Coil Slitting Machine refers to processing of metal coils up to 850MM wide. In addition to the 850MM width, the KINGREAL STEEL SLITTER metal coil slitting machine can also process coils in widths of 1350MM, 1600MM, and 2000MM, with thicknesses typically ranging from 0.3-3MM, and can be customized to meet customer production requirements.

| Coil Material | Steel/Copper/Aluminum |

| Coil Thickness | 0.3-3MM |

| Coil Width | 300-850MM |

| Coil Weight | 20 Ton |

| Slitting Speed | 0-160M/Min |

| Voltage | 380V |

| Rated Power | 300KW |

| Capacity | 300KW |

Loading trolley → Hydraulic decoiler → Roller feeding,leveling → Shear head-transition table → Deviation correction → Round knife shearing → Waste wire Rewinding-looper → Pre-separation,tension machine,length measuring roller → Winding,pressing and dividing → Unloading trolley → Hydraulic control → Electrical control

● Structure and use: This equipment is used for clamping and carrying steel rolls, opening steel rolls, and realizing the function of tension uncoiling. It consists of frame, reel, transmission system, rising and shrinking system, press material system, tension system, lubrication system, hydraulic system and so on.

● Transmission system: the frequency conversion motor drives the spindle of the unwinding machine to rotate and realize active unwinding.

Rising and shrinking system: the rising and shrinking cylinder provides tension, so that the slide seat on the spindle to produce displacement sliding, wedge-shaped slider and the slide seat to produce displacement, to realize the rising and shrinking of the reel.

● Structure and use: Used to control the synchronization and buffer of steel belt speed between slitter and feeder. The table surface is made of nylon plate to ensure that it will not scratch the plate surface. Optical switch controls the position of the steel belt in the live sleeve pit, which maintains sufficient storage capacity in the pit.

● Structure and use: The slitting machine is a device for longitudinally shearing strip coils into various widths. By changing the combined spacer, the width of the sheared product can be flexibly changed. Knife shaft adjustment adopts the lower shaft fixed, the upper shaft adjustment for worm gear synchronous adjustment of knife shaft spacing, high precision control of the gap between the upper shaft and the lower shaft. The upper and lower cutter shafts are fastened axially with nuts, and the ends of the upper and lower cutter shafts are equipped with protective sleeves for the knives. Adopting side-opening frame, it is convenient to replace the blade.

The main structure: steel plate, casting seat, synchronous gear box, universal connection drive, electric screw lifting device.

(KINGREAL STEEL SLITTER welcome all customer to visit us!)

Q1:How long will you send the proposal and offer?

A1:KINGREAL STEEL SLITTER will need about 3~7 days to design the proposal upon collecting all details of the above mentioned info necessary.

Q2:When will you tell me the price?

A2:After confirming all detailed configurations of the coil slitting machine, that KINGREAL STEEL SLITTER are able to make offer.

Q4:How long do you need to install and commissioning the coil slitting machine?

A4: Usually one week for installing and teaching workers about how to operate.

Q5:How many people will come to install and commission the coil slitting machine?

A5: Usually 1 engineer is enough to do all the things. All his expense during this travel will be paid by buyer accordingly.