KINGREAL STEEL SLITTER Sheet Coil Perforation And Rewind Machines are used to unwind, flatten, punch, and rewind metal coils of various materials. KINGREAL STEEL SLITTER coil to coil perforation lines have earned wide acclaim in the metalworking industry for their high speed and precision.

Video Display About Sheet Coil Perforation And Rewind Machine

Video Display About Sheet Coil Perforation And Rewind Machine

Description Of Coil to Coil Perforation Line

Description Of Coil to Coil Perforation Line

Coil to coil perforation line is operated by an decoiler that coils the sheet metal to the metal punching machine, which punches the sheet metal through a precise die, and after the punching is finished, the rewind machine recoiling the sheet metal to complete the whole line.

In addition, the coil to coil perforation line is equipped with a set of testing equipment to check the punching accuracy and quality to ensure the production of high quality metal coil punching products.

Main Components Detail of Coil to Coil Perforation Line

Main Components Detail of Coil to Coil Perforation Line

Decoiler is a mechanical device mainly used to unroll metal materials into sheets of certain width and thickness. Its main components include driving parts, supporting parts, adjusting parts and operating parts. Its working process is to put the metal material into the equipment, and the driving part drives the supporting part to unroll the metal material.

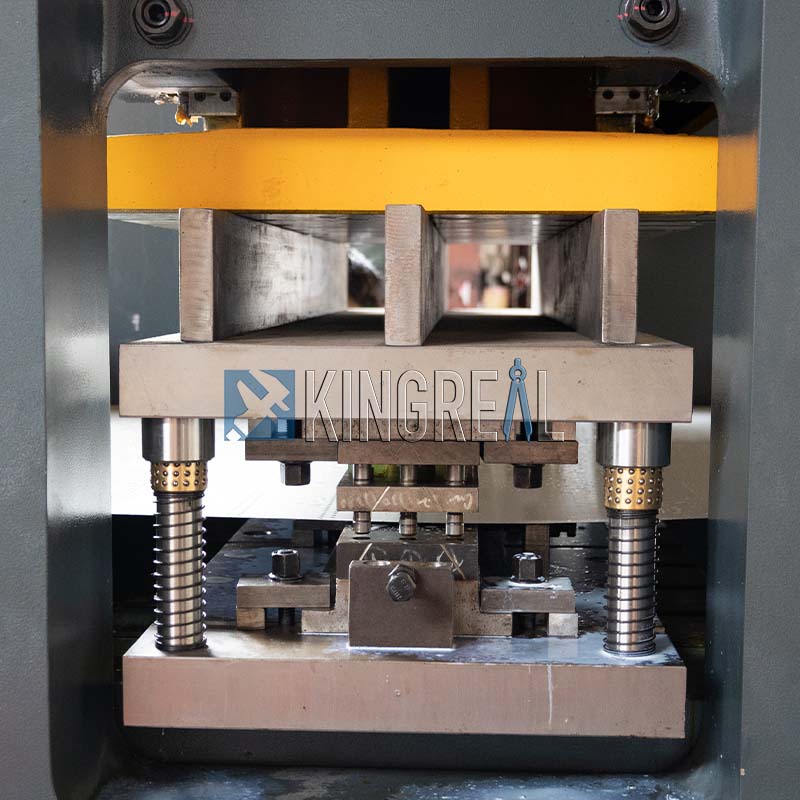

Metal punching machine is a kind of machine used for punching and processing metal plates. It mainly consists of drive system, punching unit, operation control system, etc. It can be used for a variety of processing processes such as concave punching, convex punching, open hole, and composite processing, and can achieve high efficiency punching processing.

Recoiler is a mechanical device used for winding metal materials. It has the features of high speed, high precision and automatic operation, which can realize the functions of continuous winding, controlled winding and CNC cutting.

Advantage Of Coil to Coil Perforation Line

Advantage Of Coil to Coil Perforation Line

Coil to coil perforation line adopts advanced automatic control technology, which has high working efficiency and can realize fast winding and fast reel change, thus improving production efficiency.

Micro holes perforation adopts high precision transmission system, which can realize high precision quality control and ensure the quality of winding.

Coil to coil perforation line adopts advanced safety protection technology, which has good safety performance and can effectively prevent accidents.

Technical Specification for Coil to Coil Perforation Line

Technical Specification for Coil to Coil Perforation Line

|

Maximum stamping width |

1.25m |

|

Punching speed |

45-70 times/min |

|

Maximum stamping thickness |

2.0mm |

|

Aspect |

2500x1800x2000mm |

|

Control way |

digital control |

|

Power |

7.5kW |

|

Weight |

5500kg |

More Detail Image In Factory

More Detail Image In Factory

|

|

|

|

Related Metal Perforated Making Machine

Related Metal Perforated Making Machine

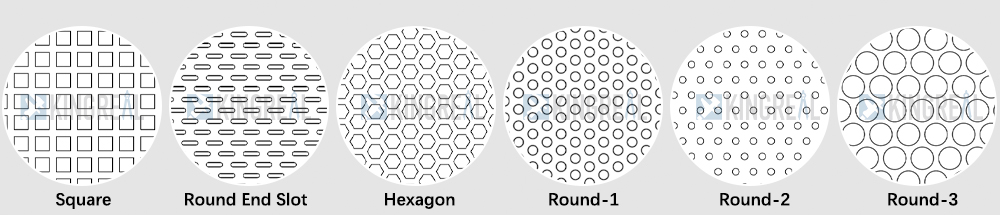

Punching Hole Type

Punching Hole Type

- Round holes: square, round, oval, etc.

- Square holes: square, rectangular, diamond-shaped, etc.

- special holes: U-shaped, V-shaped, Y-shaped, T-shaped, etc.

- Complex holes: complex pattern holes, capillary holes, hydrodynamic holes, etc.

Application Of Perforation Coil

Application Of Perforation Coil

This material is used to make automotive parts, furniture and household appliances, and is also commonly used in architectural structures, where it can be used for supporting structures and decoration.

In addition, metal perforated making machine can be used in the manufacture of certain mechanical devices, such as reels and propellers, and can also be used as a heat exchanger material.

|

|

FAQ:

FAQ:

Yes, KINGREAL STEEL SLITTER is a professional coil to coil perforation lines manufacturer, we are an OEM.

KINGREAL STEEL SLITTER has been focusing on the field of coil to coil perforation line manufacturing for more than 20 years.

There are 2 ways: either by plane or by train to Foshan/Guangzhou port. KINGREAL STEEL SLITTER will be picking you up in plane/train station, then KINGREAL STEEL SLITTER can go together.

12 months except human error, during which all parts damaged because of quality problem will be changed for free.

Parts that are out of warranty will be provided in factory price.

Within 60-80 days after receiving prepayment.