KINGREAL STEEL SLITTER Full Automatic Perforated Metal Production Line can be used in conjunction with a metal ceiling tile production line to produce high-precision perforated ceilings. This metal ceiling tile perforation line is characterized by efficient production, precise punching, and stable operation.

Video About Full Automatic Perforated Metal Production Line

Video About Full Automatic Perforated Metal Production Line

Related Project About Metal Ceiling Tile Perforation Line

Related Project About Metal Ceiling Tile Perforation Line

Description Of Metal Ceiling Tile Perforation Line

Description Of Metal Ceiling Tile Perforation Line

KINGREAL STEEL SLITTER metal ceiling tile perforation line is used for producing different kinds of perforation panel, raw material can be stainless steel, alloy aluminum and galvanize steel.

The feed material can be coil or cutted steel material. Main structure of the metal perforation panel can be designed as customers‘ requirements. The raw material can be coil or cutted steel piece.

This metal ceiling tile perforation line is specially designed for metal processing factories. The raw material is rewound and then perforated. The pattern can be customized according to the customer's drawing.

The punching machine is a high-speed type, with 150-180 strokes per minute, and the perforation diameter can be 1.8mm or 2.5mm. KINGREAL STEEL SLITTER also accept rectangular perforations or other shapes.

Working Process Of Metal Ceiling Tile Perforation Line

Working Process Of Metal Ceiling Tile Perforation Line

Hydraulic Decoiler -- Precision Straightener -- Punching Machine -- Servo Feeding Machine -- Notching And Shearing Press-2nd Precision Straightener--Flipping machine-- Automatic tiles feeding machine--Auto Bending Forming Machine

Specification Of Metal Ceiling Tile Perforation Line:

Specification Of Metal Ceiling Tile Perforation Line:

|

Maximum stamping width |

1.25m |

|

Punching speed |

45-70 times/min |

|

Maximum stamping thickness |

2.0mm |

|

Aspect |

2500x1800x2000mm |

|

Control way |

Digital control |

|

Power |

7.5kW |

|

Weight |

5500kg |

Main Part Detail Of Metal Ceiling Tile Perforation Line

Main Part Detail Of Metal Ceiling Tile Perforation Line

To respond to changing demands, KINGREAL STEEL SLITTER have hydraulic decoiler and manual decoiler with integrated hydraulic core expansion system.

For more, there is optional trolley for full-automatic metal loading.

The metal ceiling tile perforation line provides high-precision straightening. To ensure straightness of materials, KINGREAL STEEL SLITTER doubled the amount of precision rolls. As a result, finished products have higher precision.

Leveling rollers, which are made of 40Cr round bars, were thermal refined, quenched at high frequency, electroplated twice and accurately ground. They are smooth, without scratches, their hardness are above HRC62,and regulated by 4 threaded rods.

KINGREAL STEEL SLITTER metal ceiling tile perforation lines have integrated self-developed software, which is more professional and can fully perform their functions. In addition, KINGREAL STEEL SLITTER are able to provide a multi-language operation interface, including English, Russian, Spanish and so on.

This makes KINGREAL STEEL SLITTER metal ceiling tile perforation lines easy to operate, more user-friendly and provides a better user experience.

Metal Ceiling Tile Perforation Line Unit:

Metal Ceiling Tile Perforation Line Unit:

◇ Trolley Of Loading Coil

◇ Hydraulic Decoiler

◇ Straightener System

◇ Feeding System

◇ Hydraulic Press

◇ Different Perforation Molds

◇ Shear System

◇ Separating and Tension Unit

◇ Hydraulic Recoiler with Outboard Support Or Stack

◇ Coil Exit Car

◇ Hydraulic Units and Electronic Control Systems

◇ KINGREAL Metal Perforation Production Line Shipping To UAE.

What KINGREAL STEEL SLITTER Metal Ceiling Tile Perforation Line Can Do?

What KINGREAL STEEL SLITTER Metal Ceiling Tile Perforation Line Can Do?

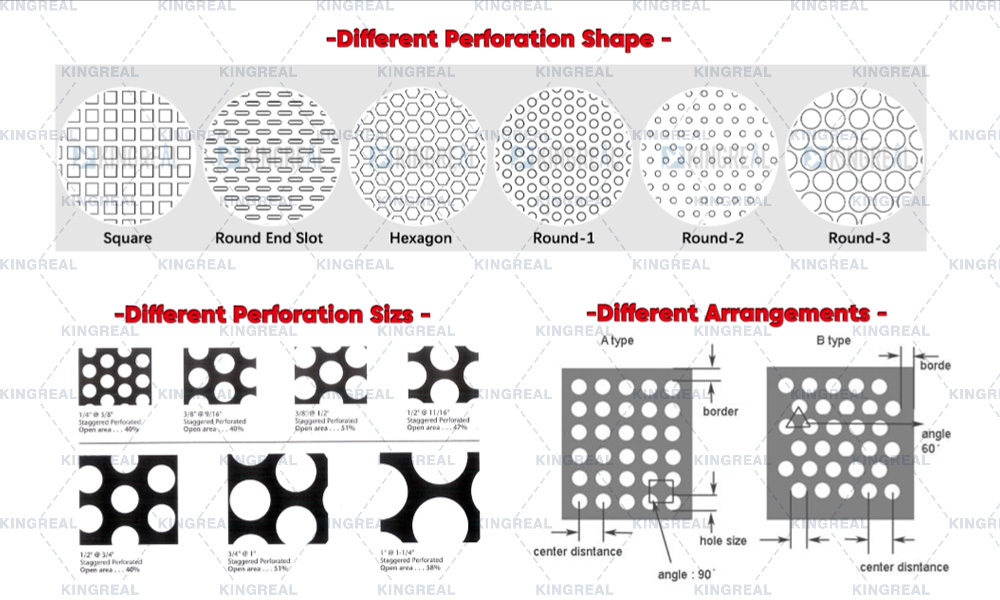

✔ Round hole perforated

✔ Square hole perforated

✔ Slotted hole perforated

✔ Hexagonal ( honeycomb ) perforated

✔ Ornamental& decorative perforated

Application Of Metal Perforated Making Machine

Application Of Metal Perforated Making Machine

1.Ideal for indoor and outdoor structures

2.Facades and cladding panel

3.Decorative surfaces

4.Architectural elements

5.Noise-resistant walls and ceilings

6.Acoustical panels for sound control

7.Sunshades to control light

8.Privacy applications

9.Air diffusers for HVAC equipment

10.Cable Tray

11.Shelf Processing

12.Angel Iron Punching

FAQ:

FAQ:

KINGREAL STEEL SLITTER is a professional metal perforated making machines manufacturer and supplier.

KINGREAL STEEL SLITTER offer different types of metal perforated making machine solutions mainly including coil to coil perforation line, metal ceiling tile perforation line, metal sheet perforated machine, etc.

KINGREAL STEEL SLITTER had helped customers to build their factories successfully all over the world, such as Russia, Middle East, South Asia, South America, etc.

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct to Foshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

KINGREAL STEEL SLITTER will pick you up at the station or airport.

12 months, during which all parts damaged because of quality problem will be changed for free.

30% deposit is paid before production, the balance paid after inspection confirmation before shipment.