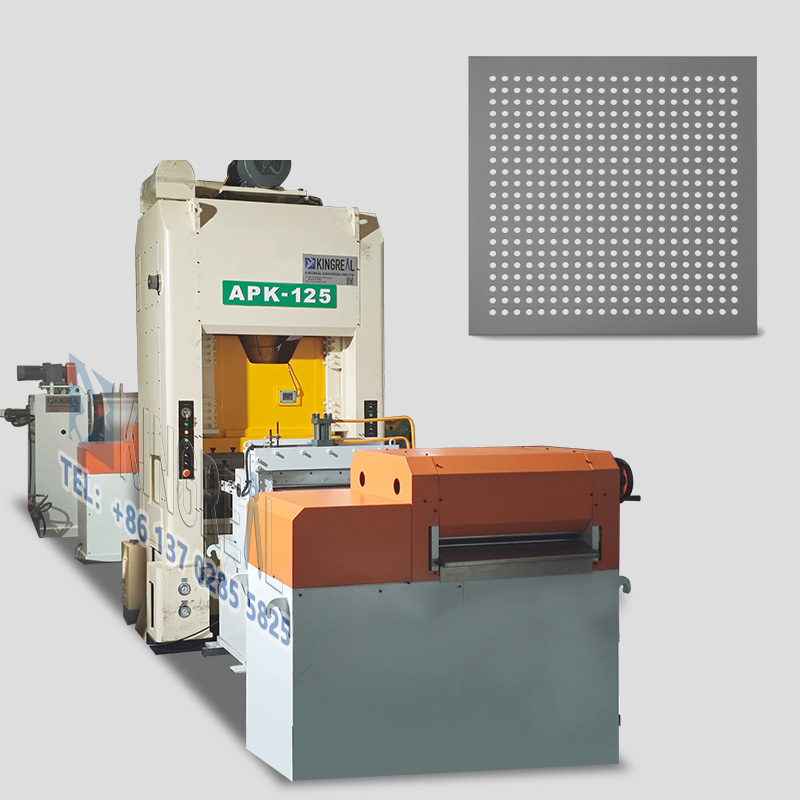

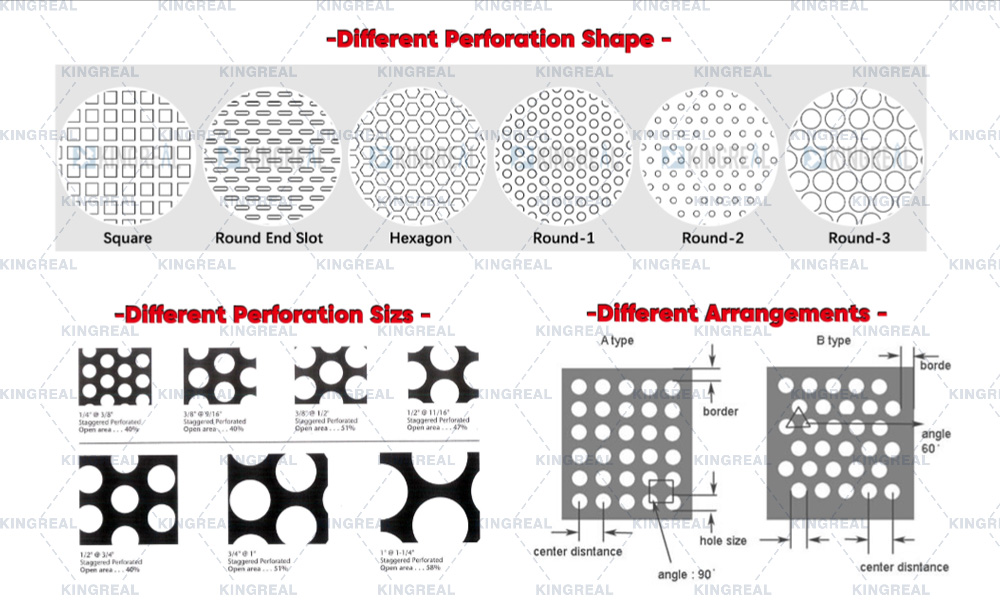

KINGREAL STEEL SLITTER Metal Sheet Coil Perforated Production Line With Cutting can process various metal raw materials to produce perforated metal coils or perforated metal sheets. The hole shape and diameter of the punching die are customized according to the customer's drawings.

One of KINGREAL STEEL SLITTER most well-liked machines in 2025 is the Metal Sheet Perforated Machine, an automated production device for processing metal sheets that has been successfully exported to countries including India, Chile, Russia, and the Middle East. In order to achieve various production outcomes, the KINGREAL STEEL SLITTER metal sheet perforated machine can be constructed with various molds and corresponding techniques. The automated control system simultaneously monitors and manages the entire production line operation. The automated control system makes it possible to create and modify production settings as well as to monitor and fault-diagnose the production process in real-time. This automated control system can decrease labor intensity and human error while increasing production efficiency and product quality.

Hydraulic Decoiler -- High Precision Straightener -- 160Ton Punching Machine -- Cutting Station -- Output Table

|

Maximum stamping width |

1.25m |

|

Punching speed |

45-70 times/min |

|

Maximum stamping thickness |

2.0mm |

|

Aspect |

2500x1800x2000mm |

|

Control way |

Digital control |

|

Power |

7.5kW |

|

Weight |

5500kg |

|

Shearing machine for metal sheet perforated machine Shearing machine is the core equipment of the whole metal sheet perforated machine, which can cut the metal sheet according to the required size. Shearing machine usually consists of cutting knife, positioning device, transmission system and other components, characterized by high shearing precision and high efficiency. |

|

|

Punching machine for metal sheet perforated machine The punching machine is a device used to perform perforation operations on metal sheets. It usually consists of piercing tool, positioning device, control system and other components, capable of realizing different shapes and sizes of piercing needs. |

|

Feeding system for metal sheet perforated machine: The feeding system is used to feed the sheet metal into the shearing and piercing machine for processing. It usually consists of feeding device, positioning device, conveyor belt and other components, which can realize automatic sheet feeding and improve production efficiency.

Control system for metal sheet perforated machine: The control system is the brain of the whole metal sheet perforated machine, which is used to monitor and control the operation of each equipment. It usually consists of PLC controller, touch screen operator interface and other components, which can realize automatic production process control and adjustment. |

|

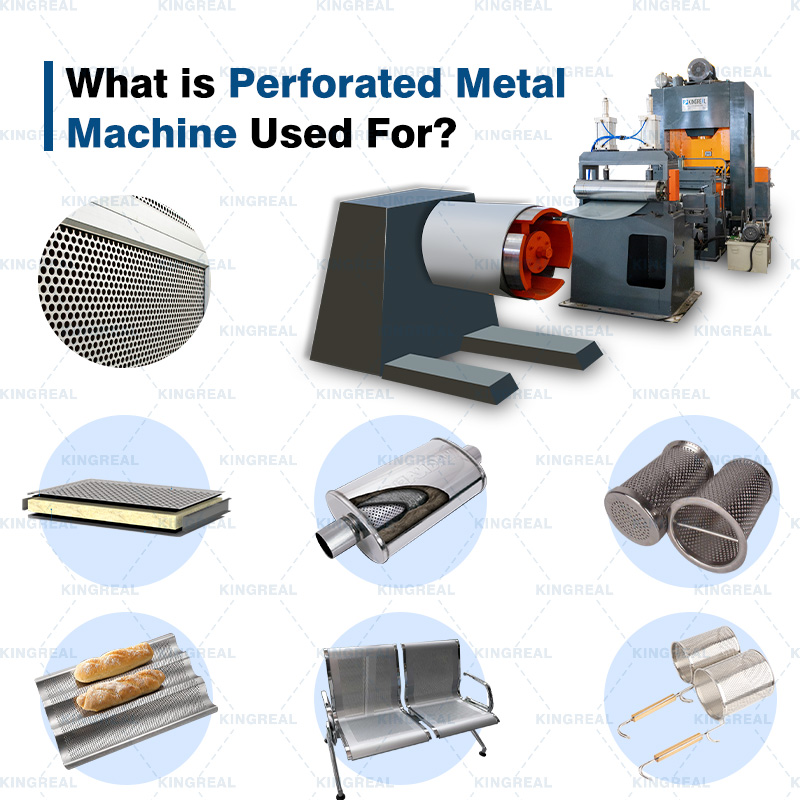

Metal sheet perforated machine is an advanced production equipment for processing perforation and shearing of metal sheets. It is widely used in various fields of manufacturing, such as automobile manufacturing, aerospace, construction and furniture manufacturing.

KINGREAL STEEL SLITTER is one of China's most professional metal sheet perforated machine suppliers. To date, KINGREAL STEEL SLITTER has collaborated closely on metal sheet perforated machine projects with customers in Morocco, Iran, Bangladesh, Brazil, and other countries. KINGREAL STEEL SLITTER engineers can provide customized machine solutions based on client drawings and actual production requirements. Furthermore, KINGREAL STEEL SLITTER custom-designs punching dies to ensure precise punching.

|

|

|

|

Metal sheet perforated machine to Bangladesh |

Metal sheet perforated machine to Morocco |

Metal sheet perforated machine to Brazil |