KINGREAL STEEL SLITTER High speed Coil Perforation Production Line can produce various specifications of perforated ceilings such as 300x300mm, 600x600mm, 1200x600mm, etc., which are widely used in decoration projects.

Video About High speed Coil Perforation Production Line

Video About High speed Coil Perforation Production Line

Description of High Speed Metal Ceiling Tile Perforation Line:

Description of High Speed Metal Ceiling Tile Perforation Line:

KINGREAL STEEL SLITTER metal ceiling tile perforation line consists of components such as an decoiler with a straightener, a punch, a shearing for length cutting and a rewind, which cooperate with each other to successfully manufacture a perforated coil.

KINGREAL STEEL SLITTER metal ceiling tile perforation line not only just perforate the metal sheet, but also can perforate the metal coil. And the greatly advantage is that can reduces raw materials costs due to mass production.

In addition, due to its systematic perforation line, it has the ability to perforate and short production times. This reduces labor and utilizes resources efficiently.

The Process of Metal Ceiling Tile Perforation Line:

The Process of Metal Ceiling Tile Perforation Line:

Step 1:

The decoiler with straightener is responsible for feeding the normal coils easily into the feed rollers of the machine.

Step 2:

Then advancing forward in the process, the punch will do its job to punch out the predefined hole, thus perforating the coil.

Step 3 :

Finally when the desired length is reached, the punching system will stop and cut by the designated shear to cut the sheet.

Depending on the customer, if they wish to perforate the entire coil, the coils will not be cut, but will immediately go to the rewinding step.

Features High Speed Metal Ceiling Tile Perforation Line:

Features High Speed Metal Ceiling Tile Perforation Line:

1. Welded steel plate frame, high body strength

2. Adopt international brand PLC control

3. Control devices such as buttons, indicator lights, AC constrictors, and air circuit breakers are imported from international brands

4. Equipped with hydraulic overload protection device

Features of Metal Ceiling Tile Perforation Line :

Features of Metal Ceiling Tile Perforation Line :

KINGREAL STEEL SLITTER metal ceiling tile perforation lines series use SIEMENS motors to ensure the stable running of the machine. Beside the motors, all

the electrical system we use high quality famous brands, Such as YASKAWA for the servo feeder motors and Omron for the PLC, etc.

This will ensure KINGREAL STEEL SLITTER metal ceiling tile perforation line running stable and long life time usage.

KINGREAL STEEL SLITTER metal ceiling tile perforation line uses a 10-inch full-color touch screen,which has aluminum profile rocker-arm structure.The design has the characteristics of beautiful appearance,simple and easy to operate.

Reference Data of High Speed Metal Ceiling Tile Perforation Line

Reference Data of High Speed Metal Ceiling Tile Perforation Line

|

Maximum stamping width |

1.25m |

|

Punching speed |

45-70 times/min |

|

Maximum stamping thickness |

2.0mm |

|

Aspect |

2500x1800x2000mm |

|

Control way |

digital control |

|

Power |

7.5kW |

|

Weight |

5500kg |

Different Ton Punching Machine Can Be Customized

Different Ton Punching Machine Can Be Customized

KINGREAL STEEL SLITTER engineers will configure metal punching machines of varying tonnages for metal ceiling tile perforation line based on customer needs. The metal punching machine's tonnage depends on factors such as hole pattern, material width, material type, and thickness. Typically, KINGREAL STEEL SLITTER uses 120-ton or 125-ton metal punching machines for metal ceiling tile perforation lines. KINGREAL STEEL SLITTER utilizes a comprehensive set of calculation formulas to ensure the selected metal punching machine has sufficient tonnage to accurately produce the desired hole pattern.

|

|

| 125ton metal punching machine | 160ton metal punching machine |

Perforated Sheet Panel Drawing Display

Perforated Sheet Panel Drawing Display

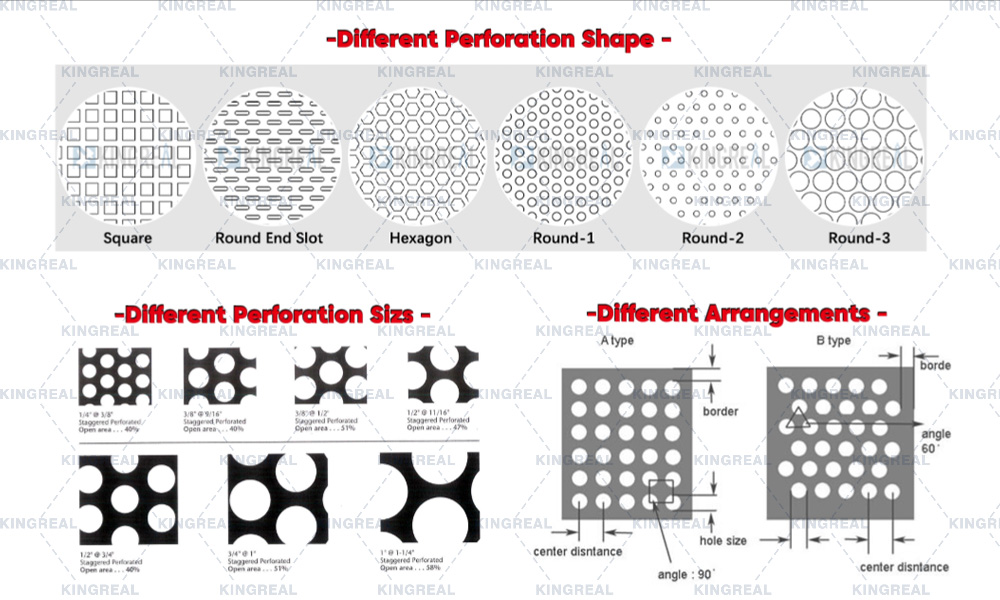

The most common patterns are round hole, long round hole, square hole, triangle hole, diamond hole, hexagonal hole, crossed hole, etc, which by the way can all be obtained with the same piercing tool, just remove half of the punch.

Apertures can be as small as 0.7mm to 3mm or even larger. The most common sizes are from 1,5 mm to 2,5 mm, the distance between the holes is usually from 4 to 6 mm. KINGREAL STEEL SLITTER will customize the punching die for metal ceiling tile perforation line according to the needs of customers.

Why choose us?

Why choose us?

In order to help our customers to solve metal ceiling tile perforation line installation problems, KINGREAL STEEL SLITTER will provide both online and local installation services

KINGREAL STEEL SLITTER has its own professional technical team. With strong professional ability and rich design experience, KINGREAL STEEL SLITTER engineers can design metal ceiling tile perforation lines according to the drawings provided by customers and the corresponding production needs.

Solve all technical problems during the production, installation and use of the machine.

As the first point of contact for customers, KINGREAL STEEL SLITTER Sale Team will provide professional services. KINGREAL STEEL SLITTER staffs will listen carefully to your needs, provide the best production solutions, and ensure you have the best service.

In order to be able to effectively solve customer needs in the first time, KINGREAL STEEL SLITTER has set up localized service points in many countries and regions, such as India, Russia, Turkey, the United Arab Emirates and Qatar.

Localized service points in other countries and regions are also in progress.