The KINGREAL STEEL SLITTER Metal Filter Perforated Making Machine is a specialized piece of equipment for producing metal filters. This metal perforated making machine creates a series of round and square holes in the metal sheet through punching technology.

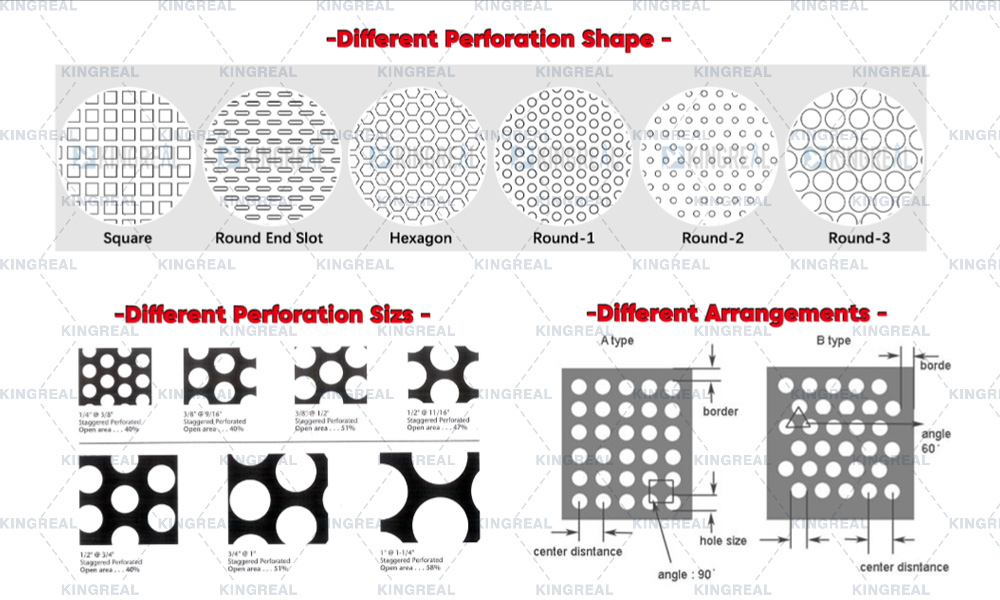

Metal Perforated Making Machine is a specialized equipment for producing metal filter , which creates a series of holes on metal sheets by punching technology, and these holes can be made into different shapes and sizes as needed.

Metal filter are widely used in filtration systems to separate solid particles from liquids or gases. Such Metal Perforated Making Machines usually include feeding systems, stamping equipment, molds, and related control systems, enabling high efficiency and precision production. Metal cartridges are usually made of stainless steel, aluminum, copper, etc., and perforated lines are able to handle these materials to produce cartridges with uniform pore sizes and distribution. These perforated filter have a wide range of applications in many industries such as chemical, food and beverage, pharmaceutical, environmental protection, etc. due to their characteristics such as high temperature resistance, corrosion resistance, high strength.

Automatic Material Decoiler-- Flattening Machine-- Punching Machine-- Recoiler

|

No |

Part |

Specification |

|

1 |

Width of material |

<1250 mm |

|

2 |

Max. Outer diameter |

Φ 1200 |

|

3 |

Maximum load |

5Ton |

|

4 |

Thickness of material |

0.3-2mm |

|

5 |

Way of relaxation |

Pneumatic relaxation |

|

6 |

Stop gauge |

2 sets, manual regulation |

|

7 |

Feeder motor power |

7.5 KW |

|

8 |

Precision Straightener Power |

3 KW |

▶ Straightener for Metal Perforated Making Machine

It is professional 9 rollers flatting device and 4 top roller and 5 bottom roller which avoid the deformation of the roller.

This part is used for flatting the coil material to make the surface flat so the punch can be more accurate. The motor is 3.0 kw and drive through gear box speed reducer motor which featured with fast response and high precision.

▶ 125 TON High speed Gantry Press for Metal Perforated Making Machine: It is a high speed gantry press which is capable of delivering 125 tons of pressure. This press is typically used for high-speed precision stamping and molding processes for a wide range of materials such as metals, plastics, and composites. Its features include a six-cylinder design, high-speed operation, and automated controls that improve productivity and product quality.

▶ Servo Motor Feeding Device for Metal Perforated Making Machine :Servo Motor Feeding Device is a device that utilizes servo motors to precisely control the feeding of materials into a machine or production line. This device can precisely control the position, speed and acceleration of the material according to the programmed parameters, thus realizing efficient and precise automatic feeding.

The main components of a servo motor feeding device typically include:

Servo motor: provides power to drive the feeding mechanism.

Controller: Receives commands and controls the motion of the servo motor.

Feed mechanism: such as rollers, belt conveyors or other mechanical devices used to physically move the material.

Sensors: monitor material position and speed, providing feedback to the controller to adjust motion.

▶ High efficiency:This metal perforated making machine can produce a large number of metal cartridges quickly, adapting to the demand of mass production.

▶ High precision: through precise molds and control systems, the metal perforated making machine can create holes with precise size and even distribution on metal plates.

▶ Versatility: Metal perforated making machine can handle metal plates made of various materials, such as stainless steel, aluminum, copper, etc., and can create holes of different shapes and sizes as needed.

▶ Durability: The metal filter has good resistance to high temperature and corrosion, and is suitable for a variety of harsh environments.

|

|

|

| Coil to coil perforation line |

|

|

|

|

|

|