KINGREAL STEEL SLITTER can provide Thick Plate Slitting Machines suitable for steel coils of different specifications. This heavy duty slitting machine can process coils with a thickness of 6-16mm and produce high-precision narrow strips for use in industries such as shipbuilding, construction, and metal processing.

Video About Thick Plate Slitting Machine

Video About Thick Plate Slitting Machine

Description Of Heavy Duty Slitting Machine

Description Of Heavy Duty Slitting Machine

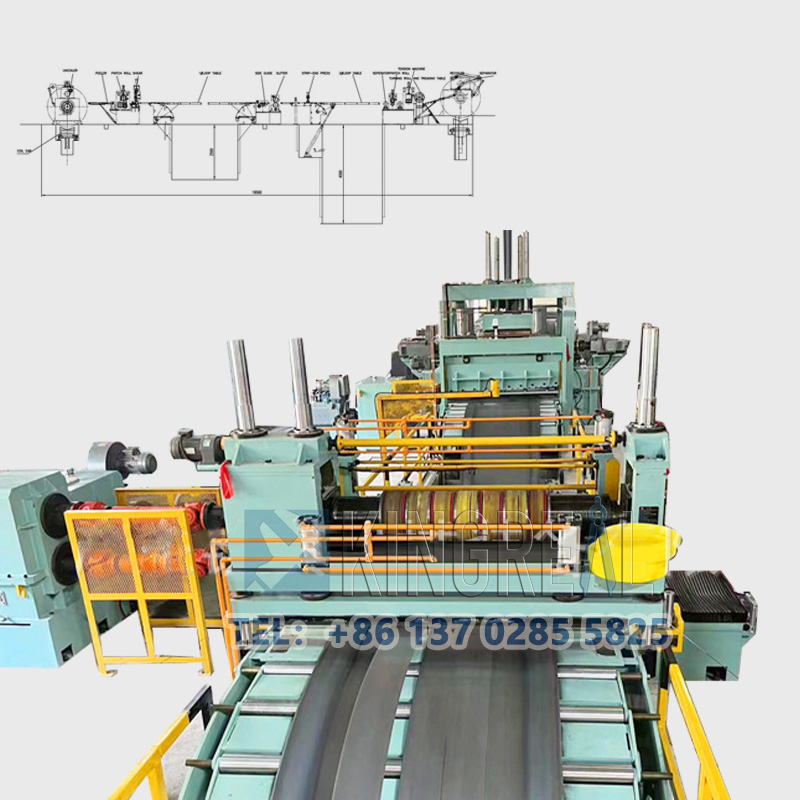

As a manufacturer in China that has specialized in the field of metal coil slitting machines for many years, KINGREAL STEEL SLITTER can provide customers with customized heavy duty slitting machine. Usually, this heavy duty slitting machine can process coils with a thickness of 6-16mm.

This heavy duty slitting machine is specially designed to slitting sheet material into specified width and rewinding. After KINGREAL STEEL SLITTER special design, this coil slitting machine can better adapt to these materials, such as stainless steel, aluminum strip, copper plate, cold-rolled steel and hot-rolled steel, etc., and perform precise slitting.

The heavy duty slitting machine is widely used in metal sheet processing industry such as automobile, agricultural vehicle, container, home appliance, building materials, construction material, etc.

KINGREAL STEEL SLITTER Heavy Duty Slitting Machine Main Components

KINGREAL STEEL SLITTER Heavy Duty Slitting Machine Main Components

1.Trolley for loading coil

2.Hydraulic decoiler

3.Pinching device

4.Leveling

5.Loop bridge

6.Side guiding

7.Slitting machine

8.Scrap recoiler

9.Separator and tension device

10.Rewinding

11.Hydraulic system

12.Pneumatic system

13.Electrical control system

Technical Process Of Heavy Duty Slitting Machine

Technical Process Of Heavy Duty Slitting Machine

Trolley for loading coil → Hydraulic decoiler → Tension station → Straightener → Loop bridge → Slitting machine → Coil guide → Pit loop → Separation → Rewind

Specification Of Heavy Duty Slitting Machine

Specification Of Heavy Duty Slitting Machine

|

Machine Type |

Heavy Duty Coil Slitting Machine |

|

Coil Material |

HR/CR steel, stainless, aluminum, copper, silicon,etc. |

|

Coil Thickness |

6.0~16.0mm |

|

Coil With |

500-1600mm |

|

Coil O.D |

1600mm(Max) |

|

Coil Weight |

20 T |

|

Slitting Motor |

200KW DC Motor |

|

Cutter Shaft |

360 x 2250mm |

|

Slitting Strip |

Max.20 strips |

|

Recoiler Motor |

250kW DC |

|

Line Speed |

Max.220m/min |

Feature Of Heavy Duty Slitting Machine

Feature Of Heavy Duty Slitting Machine

Strength and sturdiness are extremely important for slitter. KINGREAL STEEL SLITTER considered the structural design and material usage of the heavy duty slitting machine in the design stage. Through strict manufacturing process and selection of high-quality components, the high-performance operation of the heavy duty slitting machine is ensured.

The coil loading cart has a support platform with two rotatable rollers on the edge. One drum is holding the jumbo firmly while the other is loading the coils onto the double cone decoiler. The double rollers on the coil car platform rotate synchronously with the unwinding mandrel.

AC motors and reducers drive pinch machines and five-roll levelers and five-roll tension, while DC motors and reducers drive slitter and winders.

Final Slit Coil Display

Final Slit Coil Display

Why Choose Us?

Why Choose Us?

KINGREAL STEEL SLITTER is a professional manufacturer and supplier of coil processing line.

KINGREAL STEEL SLITTER offer full solutions in coil processing equipment, which including high speed coil slitting line, copper slitting machine, simple slitting machine, cut to length line machine, fly shearing cut to length machine, etc.

KINGREAL STEEL SLITTER has a professional team and rich project experience, can provide you with the best service, welcome to contact us.

1. Technical Team

KINGREAL STEEL SLITTER has its own professional technical team.

With strong professional ability and rich design experience, KINGREAL STEEL SLITTER engineers can design heavy duty slitting machines according to the drawings provided by customers and the corresponding production needs.

Solve all technical problems during the production, installation and use of the machine.

2. After-Sale Team

As the first point of contact for customers, KINGREAL STEEL SLITTER Sale Team will provide professional services.

KINGREAL STEEL SLITTER sales will listen carefully to your needs, provide the best production solutions, and ensure you have the best service.

3. Local After-Sale

In order to be able to effectively solve customer needs in the first time, KINGREAL STEEL SLITTER has set up localized service points in many countries and regions, such as India, Russia, Turkey, the United Arab Emirates and Qatar.

Localized service points in other countries and regions are also in progress

1. The role of tension control of metal coil slitter machine?

2. How to adjust the tension of the steel slitting machine?

3. How to do a good job of slitting machine acceptance?

4. How To Acceptance Of The Coil Slitting Machine?

5. How to improve the slitting efficiency of coil slitting line?