KINGREAL STEEL SLITTER double slitter head coil slitting machine is equipped with two independent slitting heads, which can process multiple coil sections simultaneously, significantly improving production efficiency. The double slitter head coil slitting machine increases the flexibility of slitting width and reduces downtime during changeover, making it an ideal choice for high-volume production environments.

Video About Double Slitter Head Coil Slitting Machine

Video About Double Slitter Head Coil Slitting Machine

Description Of Double Slitter Head Coil Slitting Machine

Description Of Double Slitter Head Coil Slitting Machine

KINGREAL STEEL SLITTER double slitter head coil slitting machine is one of our most feature product. In order to maximize the slitting speed of the double slitter head coil slitting machine, KINGREAL STEEL SLITTER designed this double slitter head coil slitting machine to reduce the time for changing the knife seat and improve production efficiency. The maximum production speed reaches 220m/min.

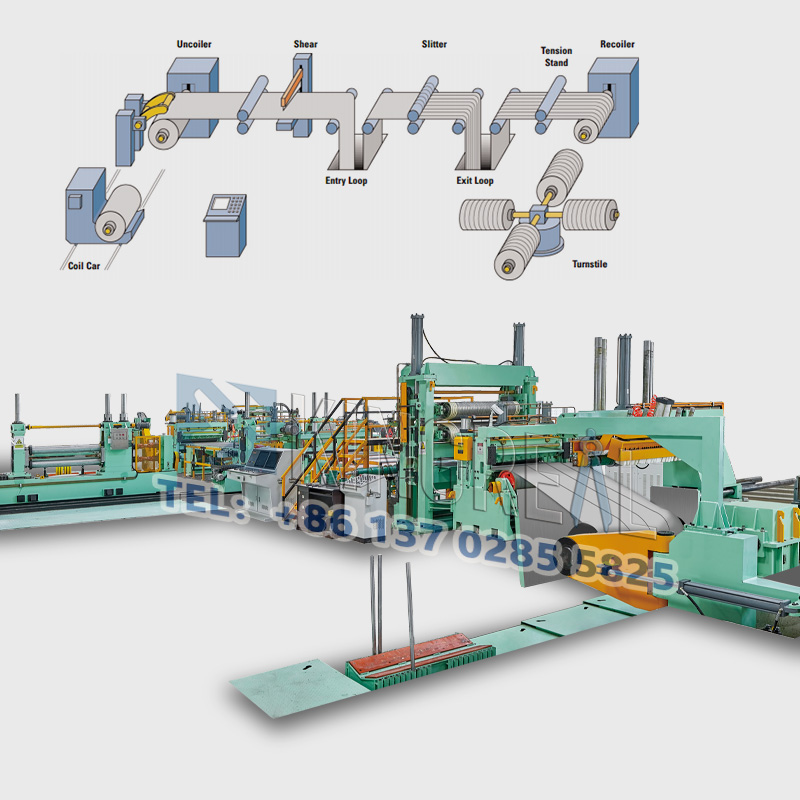

The double slitter head coil slitting machine consists of an decoiler with a coil car, a clamping and double slitting device, a high-precision slitter for quick exchange, a waste rewinder, a side guide, a winding machine, a tensioning device, and a hydraulic winder with the coil car.

High Speed Double Slitter Head Coil Slitting Line introduction

High Speed Double Slitter Head Coil Slitting Line introduction

Variation from one slitting head to the other: one undercarriage for a double slitting head walks on longitudinal rails, the in-line slitting head goes on the undercarriage, the undercarriage moves the other slitting head facing Slitting on the line position, then the other head moves to the line position, the exchange only takes 30 minutes.

The double slitting heads can be the same, or one can be larger and the other smaller. Larger slitters are suitable for slitting of larger thicknesses, while smaller slitters are suitable for slitting of small thicknesses. In this way, high-precision, high-efficiency performance is achieved.

Double slitting heads increase the flexibility and efficiency of the double slitter head coil slitting machine and are very popular with large steel mills that require large volumes of slitting coil.

Working Process Of Double Slitter Head Coil Slitting Machine

Working Process Of Double Slitter Head Coil Slitting Machine

Decoiler → Clipping and shearing → Guiding → Slitting machine→ Winding edge material →Tension → Rewinding → Unloading of small rolls → Packaging

Double Slitter Head Coil Slitting Machine Parameters

Double Slitter Head Coil Slitting Machine Parameters

|

Material of raw materials |

stainless steel, cold-rolled steel. |

|

Raw material thickness |

0.2mm-2.0mm |

|

Raw material width |

300-1550mm |

|

Raw material roll inner diameter |

Φ508mm |

|

Raw material roll outer diameter |

≤Φ1800mm |

|

Raw material volume weight |

≤12 tons |

|

Slitting speed |

0-80m/min (normal working) |

|

Total power |

about 150KW |

|

Floor area |

about 18m × 6m |

|

No. |

Name |

Unit |

|

1 |

Coil Load Trolley |

1 unit |

|

2 |

Hydraulic Decoiler with Unwinding device |

1 set |

|

3 |

Material shovel, Two rollers pinch, Hydraulic Shearing Machine |

1 set |

|

4 |

#1 Loop Bridge |

1 unit |

|

5 |

Guide Align |

1 unit |

|

6 |

Main coil slitting machine |

1 set |

|

7 |

|

1 set |

|

8 |

#2Loop bridge |

1 set |

|

9 |

Hydraulic tension station |

1 set |

|

10 |

Uncoiler |

1 set |

|

11 |

Unloading trolley |

1 unit |

Advantage Of Double Slitter Head Coil Slitting Machine

Advantage Of Double Slitter Head Coil Slitting Machine

The double slitter head coil slitting machine achieves a slitting machine speed of 220m/min by reducing the time for changing the tool holder, improving production efficiency and improving economic benefits for customers.

The straightening machine is a device on the high-precision double slitter head coil slitting machine, which is used to straighten the metal coil and eliminate wrinkles on the surface of the coil.

Components Detail for Double Slitter Head Coil Slitting Machine

Components Detail for Double Slitter Head Coil Slitting Machine

● Hydraulic decoiler and Unwinding device

|

Structure |

Steel plate welded frame, hydraulic expansion and contraction mandrel |

|

Quantity |

1 set |

|

Load-bearing |

20T |

|

Steel coil inner diameter |

Φ508mm |

|

Steel coil outer diameter |

MAX: Φ1800mm |

|

unwinding power |

11KW motor; |

● Plate head, lead material, pinch leveler, plate head shear

|

Structure |

Steel plate welded base and frame |

|

Quantity |

1 |

|

Material |

GCr15 |

|

Pinch Roll Quantity/Diameter |

2×Φ180mm |

|

Main motor power |

AC30Kw motor |

● Main Slitting Machine

|

structure |

Steel plate welded heavy-duty frame and slider, hydraulic power source |

|

quantity |

1 set |

|

scissors form |

Four-sided scissors, all four blades can be used |

|

Blade material |

Cr12MoV |

|

Blade origin |

Anhui |

KINGREAL STEEL SLITTER Featured Metal Slitting Machine:

KINGREAL STEEL SLITTER Featured Metal Slitting Machine:

|

|

|

|

FAQ

FAQ

KINGREAL STEEL SLITTER factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct toFoshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

KINGREAL STEEL SLITTER will pick you up at the station or airport.

1. Thickness of the coil (min-max)?

2. Coil width (min-max)?

3. What is your steel material?

4. Coil weight (max)?

5. How many pieces of maximum thickness do you need to slit?

6. How many tons do you need per day or per month?

Yes, KINGREAL STEEL CLITTER are a manufacturer. We have a factory and our own technical team, feel free to visit us.

Coil diameter, thickness range, application, raw material steel grade, coil weight and degree of automation.

1. How to operate the coil slitting machine correctly?

2. Detailed operation process of the coil slitting machine

3. What is the role of the sensor in the coil slitting machine?