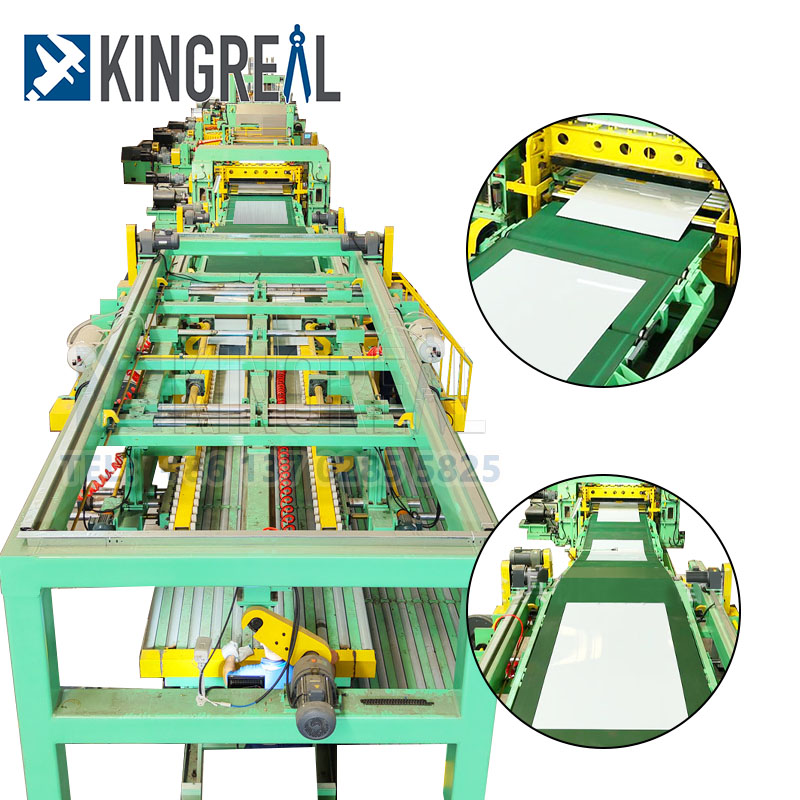

The metal cut to length machine is mainly composed of a variety of equipment such as decoiler, shearing machine, feeding system, etc. The working principle of the metal cut to length line is to cut the metal coil horizontally through the cutting tool, so as to achieve accurate cutting of the metal coil.

1. Decoiler for metal cut to length line

The decoiler is the starting point of the entire metal cut to length machine process. It is responsible for clamping and unfolding the coil to ensure that it is smoothly fed into the subsequent equipment.

There are many types of decoilers, including single-core and double-core types. The former is suitable for smaller coils, while the latter is more suitable for large coils.

2. Straightener for metal cut to length line

The primary goal of the straightener is to straighten the coil to get rid of coil bending or warping. This stage is absolutely necessary to guarantee cutting precision. Cutting before straightening the material will directly influence the ensuing cutting result and produce poor cutting quality.

3. Feeder for metal cut to length machine

The feeder feeds the shearing machine the straightened material. Direct feeding's accuracy determines the ultimate cutting length; hence, servo motors and electronic control systems are typically used by more sophisticated feeders for high-precision feeding.

This accurate feeding can guarantee the precision of every cut and create the basis for the effective functioning of the whole metal cut to length line.

4. Shearing machine for metal cut to length line

The shearing machine is the core cutting mechanism in the metal cut to length machine. Depending on the type and thickness of the material, the shearing machine can be a rotary shearing, a swing shearing, a fixed shearing or a flying shear.

Each metal cut to length machine has its advantages and disadvantages and can cope with different cutting needs. The efficiency and stability of the shearing machine are important factors to ensure the production efficiency of the metal cut to length line.

5. Stacker for metal cut to length machine

Finally, the cut workpieces are collected and neatly arranged by the stacker, ready for the next stage of processing or transportation. Efficient stacking can not only reduce the time of manual operation, but also improve the overall efficiency of the metal cut to length line.

1. Precision and accuracy

Using sophisticated control systems and very accurate mechanical structures, metal cut to length lines guarantees consistent and exact cuts. Keeping product quality and fulfilling demanding industry standards depends on this.

2. Improved productivity

Metal cut to length machines can process large amounts of material in a short period of time, reducing manual labor while increasing overall output. This efficient production model enables companies to gain an advantage in the fierce market competition.

3. Versatility in material handling

Including steels, aluminum, and copper, metal cut to length lines can handle a wide range of materials. Its adaptable design lets metal cut to length machines be modified to meet many requirements, fit a range of cutting widths and lengths, and find broad applications across many sectors.

4. Cost-effectiveness

Metal cut to length lines offer a cost-effective answer by lowering material waste and lowering manual intervention. Its benefits of automation and accuracy can save a lot of resources and time, thereby helping businesses achieve better results in cost management.

1. According to material thickness

Light gauge cut to length line: can process coils with a thickness of 0.2-3mm.

Medium gauge cut to length line: suitable for coils with a thickness of 0.3-6mm.

Heavy gauge cut to length line: can process coils with a thickness of 6-20mm.

2. According to the metal material

Stainless steel cut to length machine,

Cold rolled cut to length machine,

Hot rolled cut to length machine...

3. According to the shearing method

Fly shearing cut to length line: suitable for fast cutting, usually up to 80m/min speed.

Swing shearing cut to length line: suitable for cutting a variety of materials, relying on the rotation of the knife frame to achieve the shearing process, the speed can reach 80m/min.

Fixed shearing cut to length line: it will stop when cutting, the speed is slow, about 50m/min.

Rotary shearing cut to length line: rotating high-speed shearing, no stamping caused by stopping shearing, the speed can reach 80m/min

Particularly in the cutting and processing of metallic products, many sectors use metal cut to length lines extensively. Working this line demands professional expertise and tight operating processes to guarantee effective and safe metal material cutting.

1. Metal cut to length line in automotive industry

In the automotive industry, metal cut to length machines are used to cut materials for body, frame and other parts. Its high precision ensures that each part meets strict specifications, thereby ensuring the safety and performance of the entire vehicle.

2. Metal cut to length line in construction industry

In the construction industry, metal cut to length lines are used to cut materials for beams, plates and other structural components. The ability to efficiently process large amounts of material is a significant advantage, making construction more efficient.

3. Metal cut to length line in metal manufacturing

In the metal manufacturing industry, metal cut to length machines are used to cut plates, steel plates and coils into various lengths for further processing. This flexibility enables it to meet the needs of different customers.

Businesses buying a metal cut to length machine should evaluate cutting precision, equipment stability, production size, and processing needs among other criteria.

Understanding the manufacturer's technical level, after-sales service, and equipment production capacity is equally vital.

The key to guarantee long-term stable functioning of metal cut to length line is regular maintenance and attention. This comprises cleaning, lubrication, component replacement, and system inspection of metal cut to length machine to guarantee equipment operation and safety.Through scientific maintenance, enterprises can extend the service life of metal cut to length line, reduce failure rate, and thus maintain efficient production capacity.