A steel coil slitting machine is a machine designed to cut wide metal coils into the required width or length. It usually contains a fast tool change system, a decoiler and a slitting machine system, using high-precision knives.

This steel coil slitting machine is not only reliable but also flexible, suitable for slitting all types of steel and metal rolled coils. With steel coil slitting machines, factories can efficiently produce steel coils of various widths and specifications.

In practical applications, steel coil slitting lines can accurately slit the rolled metal rolls coming from the rolling mill. After slitting, these metal coils can meet customers' needs for standard and precise widths, thereby reducing material costs and improving production efficiency.

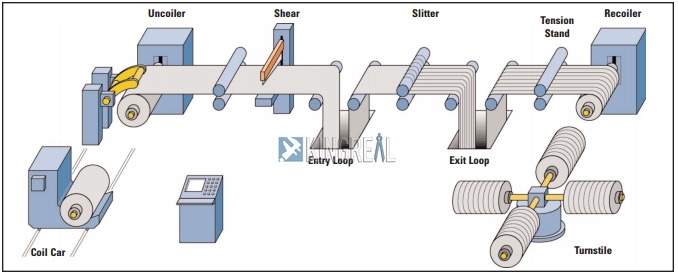

The basic structure of a steel coil slitting line usually consists of three main parts: a decoiler, a slitter, and a recoiler. These components work together to ensure that the slitting process is efficient and precise.

1. Decoiler for steel coil slitting machine

The decoiler is the first process of the steel coil slitting machine. Its main function is to load the metal coil or main coil onto the steel coil slitting line.

The decoiler can be in double cone form or single end form with expanding mandrel. Double cone decoiler is suitable for heavier loads, while mandrel type is suitable for light and heavy applications.

Through the decoiler, the raw material is loaded and flattened to eliminate surface defects and prepare for the subsequent slitting process.

2. Slitter for steel coil slitting machine

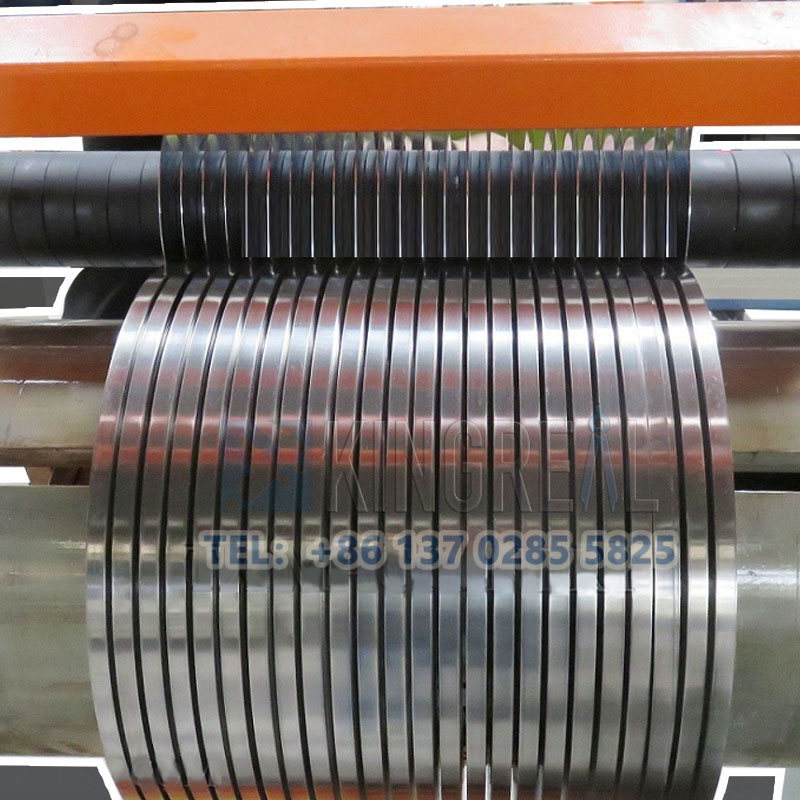

The slitter is the core part of the steel coil slitting machine. Its main task is to split the metal coil into multiple slits of predetermined width.

The slitter usually consists of two parallel mandrels and a tool equipped with a rotating knife.

During the slitting process, the knife will partially push the coil, causing cracks or breaks on both sides of the metal material.

To ensure the cutting quality, the slitter is usually equipped with a rubber stripper ring to prevent burrs.

3. Recoiler for steel coil slitting line

The recoiler is responsible for rewinding the slit coil into a coil. Most recoilers use an expanding mandrel that can be adjusted to the diameter of the coil.

By working with a separation disc, the recoiler can effectively prevent the staggering of slit coils and ensure the quality of the finished product.

The working principle of steel coil slitting line can be divided into three main stages: unwinding, slitting and rewinding.

1.Unwinding stage of steel coil slitting line

In the unwinding stage, the metal coil is loaded onto the decoiler, and after flattening, the coil is ready to enter the slitting machine. The design of the decoiler is to ensure that the coil reaches the best flatness and defect-free state before entering the next step.

2.Slitting stage of steel coil slitting line

In the slitting stage, the unwinding coil enters the slitting machine for slitting. The knife of the steel coil slitting machine will slit the coil to a predetermined width, and some waste will be generated at this time, which will be processed by the rewinder. After cutting, the steel coil slitting line will send the multiple slit coils separated by the steel coil slitting machine to the rewinder for winding.

3.Rewinding stage of steel coil slitting line

The rewinding stage is the last step of the steel coil slitting machine, and the slit coil is rewound by the recoiler. At this time, the recoiler adjusts the core diameter to ensure the stability and consistency of each coil when winding.

This process not only improves production efficiency, but also ensures the quality of the finished product.

1. High-quality slitting effect

The steel coil slitting machine can achieve high-quality and strict production cutting, reduce the generation of burrs, and make the cut coils smoother. Customers can directly obtain steel coil products of standard and precise width through this steel coil slitting machine, reducing material waste.

2. High efficiency and accuracy

The high level of automation of the steel coil slitting machine makes it easier to operate, and productivity and accuracy have been significantly improved. From the fast loading of the decoiler to the high-precision automatic stacking device, the entire system is constantly optimized to achieve high performance and fast operation.

3. Reduce production costs

Through the steel coil slitting line, enterprises can reduce the need for secondary processing and reduce production costs.

In high-volume applications, steel coil slitting machines are particularly advantageous, as they can quickly and efficiently slit coils into the required specifications to meet market demand.

|

|

|

When choosing the right steel coil slitting line for your application, there are several factors to consider, including component type, mandrel size, tool type, horsepower, and tensioning device. These factors will directly affect the processing effect of the metal coil material to be cut.

1. Component Type of steel coil slitting machine

When choosing a steel coil slitting line, first understand the type and function of its main components. The design and performance of the decoiler, slitter, and recoiler will directly affect production efficiency and cutting quality.

2. Mandrel Size for steel coil slitting line

The choice of mandrel size is also very important. According to the specifications of the coil to be cut, choosing the right mandrel can improve the adaptability and stability of the steel coil slitting machine and ensure the smooth progress of the slitting process.

3. Tool Type for steel coil slitting line

The choice of tool is directly related to the slitting effect and production efficiency. High-precision tools can provide better slitting quality and reduce burrs and other defects.

4. Horsepower and tensioning device for steel coil slitting line

The choice of horsepower determines the working capacity of the steel coil slitting machine, while the tensioning device ensures the stability and consistency of the coil during slitting and winding.