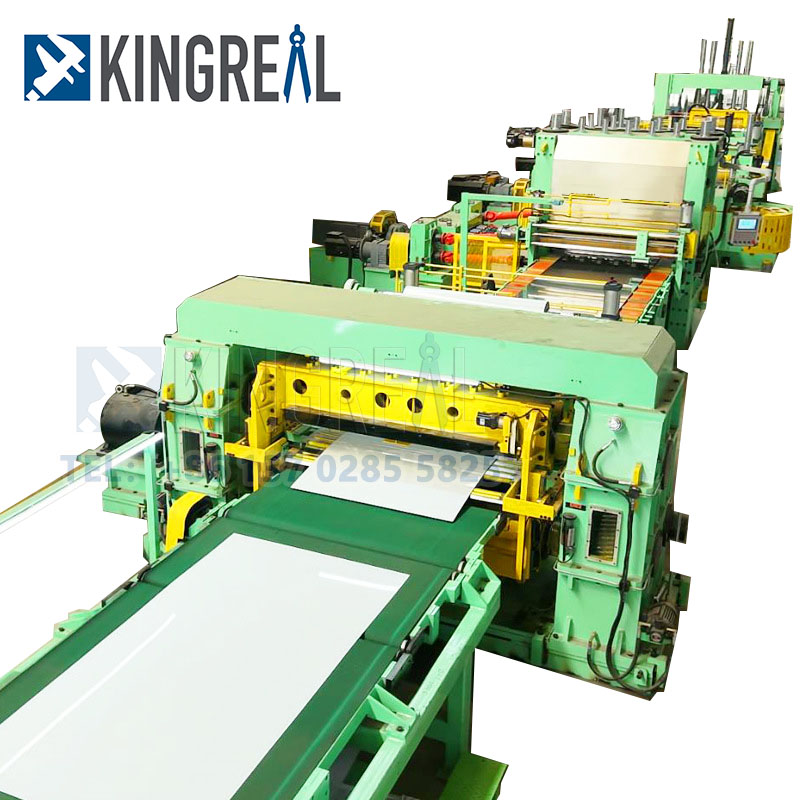

Stainless steel cut to length machine is an indispensable and important equipment in modern manufacturing industry.

It realizes efficient and accurate cutting of stainless steel coils through the coordinated work of multiple precision components.

In this article, KINGREAL STEEL SLITTER will discuss the core components of stainless steel cut to length line with you, analyze its work process, and help you better understand the function and importance of stainless steel cut to length machine.

In the work process of stainless steel cut to length machine, raw material handling system is the first crucial step. It is mainly composed of decoiler, leveling machine and centering device.

1.1 Decoiler for stainless steel cut to length line

Decoiler is usually divided into cantilever type and double cone head structure. The former is suitable for smaller coils, while the latter is more suitable for larger and heavier coils. The adjustability of unwinding speed enables stainless steel cut to length machine to adapt to different production needs.

At the same time, hydraulic tensioning system and guide device ensure the stability of material during unwinding process to avoid material deviation caused by uneven tension.

1.2 Leveling and centering device

The leveling machine is an indispensable part of the stainless steel cut to length machine. Its multi-roller structure (usually 5-11 rollers) can effectively eliminate the wave and bending deformation of the material, ensuring that the leveling accuracy reaches ≤0.5mm/m.

The centering device uses photoelectric sensors and hydraulic correction cylinders to adjust the lateral position of the strip in real time, thereby ensuring the precise positioning of subsequent processes.

The core function of the stainless steel cut to length line is shearing processing, so the feeding and sizing system and the cross-cutting machine group are its key parts.

2.1 Feeding and sizing system for stainless steel cut to length line

The feeding roller group consists of an active roller and a driven roller, and the surface is covered with wear-resistant rubber to ensure that the material does not slide during the feeding process.

Driven by a servo motor, the feeding accuracy can reach ±0.1mm, and fixed-length feeding of 500-6000mm can be achieved. The fixed-length baffle adopts a ball screw and a linear guide structure, and the position is adjusted electrically, and a closed-loop control is formed with an encoder to ensure the accuracy of the feeding length.

2.2 Cross-cutting unit for stainless steel cut to length machine

The cross-cutting unit is the core of the shearing process of the stainless steel cut to length line.

It consists of an upper blade shaft, a lower blade shaft and a hydraulic pressing device. The blade material is usually Cr12MOV, with a hardness of HRC58-62.

The shearing speed can reach 10-60 times/minute, and it can process plates with a thickness of 0.1-6mm. The gap adjustment mechanism allows manual or electric adjustment of the blade gap to ensure high standards of shearing quality.

|

|

In the work of the stainless steel cut to length machine, waste handling is as important as finished product stacking.

3.1 Waste shearing and collection

The edge wire shear is a device installed on both sides of the shearing unit, which can shear the edge waste into small segments of 50-100mm and send it to the chip collection box through the waste conveyor belt.

In addition, the crusher (optional) performs secondary crushing on the thick plate waste, and the particle size is controlled at ≤100mm for subsequent recycling.

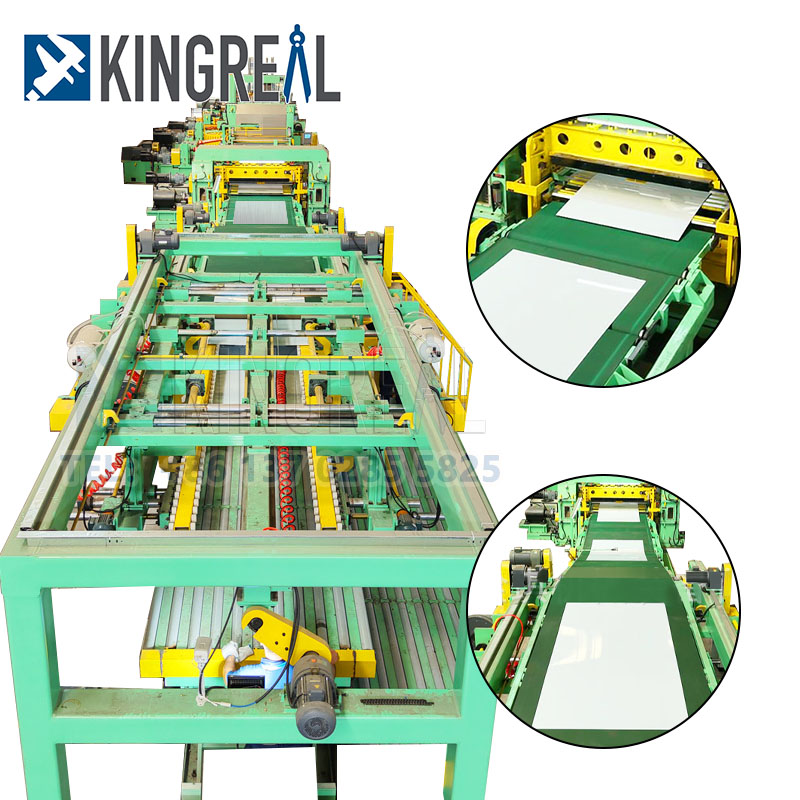

3.2 Stacking device for stainless steel cut to length line

The stacking device ensures the effective management of finished products. The speed of the conveyor belt is adjusted to 0.5-2m, and the anti-slip rubber layer on the surface prevents the finished product from sliding.

The stacking mechanism consists of a lifting platform, a push plate and a positioning baffle, which can automatically stack multiple layers of finished products (height ≤1.5m), and is equipped with a weighing sensor to monitor the weight of the finished products to ensure the standardized stacking of the finished products.

The hydraulic system and electrical control system are the power sources to ensure the efficient and stable operation of the stainless steel cut to length machine.

4.1 Hydraulic system for stainless steel cut to length line

The power unit of the hydraulic system consists of a hydraulic pump, an oil tank and a cooler, which provides power for the unwinding tension, the pressing device, etc.

The choice of the hydraulic pump (such as a gear pump or a Guisai pump) affects the flow rate of the hydraulic system (20-100L/min), while the capacity of the oil tank (500-2000L) affects the stability of the system.

The cooperation of actuators such as hydraulic cylinders and proportional valves realizes precise control of the action.

4.2 Electrical control system for stainless steel cut to length line

The electrical control system usually adopts Siemens or Mitsubishi brand PLC, integrated servo drive, frequency converter and human-machine interface (HMD), which can set process parameters and monitor the operating status of the stainless steel cut to length machine in real time.

The sensor network includes encoders, tension sensors and photoelectric switches, etc., forming a closed-loop control to ensure the automatic operation of the stainless steel cut to length line.

In addition to the core components, the stainless steel cut to length machine is also equipped with a variety of auxiliary devices to improve production efficiency and safety.

5.1 Dust removal system for stainless steel cut to length line

The dust removal system removes debris from the surface of the sheet through a vacuum cleaner or a blower to avoid contamination of the finished product, thereby improving the quality and appearance of the product.

5.2 Safety protection device for stainless steel cut to length line

Safety protection devices are important measures to ensure the safety of operators, including emergency stop buttons, safety light curtains, protective covers, etc. These devices can respond to emergencies in a timely manner and avoid safety accidents.

5.3 Lubrication system for stainless steel cut to length machine

The lubrication system uses an automatic oil supply device to lubricate the guide rails, lead screws and other components regularly to reduce wear and increase the service life of the stainless steel cut to length line.

|

|

The precision design and efficient operation of the core components of the stainless steel cut to length line are the basis for achieving accurate cutting of stainless steel coils.

Through a comprehensive analysis of raw material processing, shearing processing, waste processing, hydraulic and electrical control, and auxiliary devices, we can see that the stainless steel cut to length machine not only plays an important role in the manufacturing industry, but also makes positive contributions to improving production efficiency, ensuring safety, and reducing costs.

In the future development, the technology of the stainless steel cut to length line will continue to improve, and the trend of intelligence and automation will further promote the expansion of its application areas.

Hope this article can help you have a deeper understanding of the core components of the stainless steel cut to length machine and its importance in modern manufacturing.