KINGREAL SLITTER offer the high precision cut to length production line, which including decoiler, leveler, fly shearing machine and auto stacker. It has been successfully sold to Russia, Saudi Arabia, Turkey and India, etc. Contact us for a more detailed quotation.

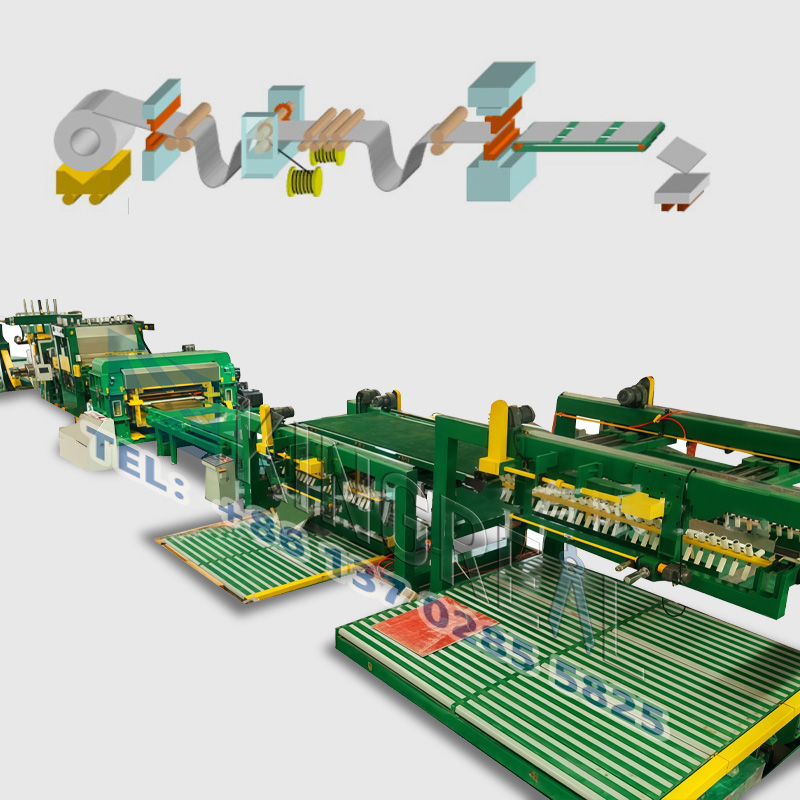

High-precision cut to length production line is a kind of automated equipment for sheet metal processing, which can decoiler, leveler and cut to length the metal coil into the required length and width of flat sheet material.

KINGREAL steel coil cut to length line production line usually includes components such as uncoiler, leveler, cut-to-length shear (flying shear), conveyor and stacker. It is widely used in industries such as stainless steel products, electrical appliances, vehicles and machinery manufacturing, etc. It is particularly suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel and various types of metal coils after surface coating.

Advantages of these lines include a high degree of automation, increased productivity, material savings, and the ability to produce extremely accurate cut-to-length sheets. For example, some high-precision metal cut-to-length lines are capable of achieving shear accuracies of up to ±0.1 μm, which meets high manufacturing standards.

KINGREAL STEEL SLITTER has been engaged in coil processing equipment for more than 20 years, and has its own technical department and production workshop to ensure the quality of the machines and equipment. We have already sold our CTL lines to Russia, Turkey, Saudi Arabia and Greece, and are able to customize the design according to the customer's needs.

Material Upload → Hydraulic uncoiler feeding material → Pinch Rollers to enter the 6 layers precision Leveling Machine → Short Looper Station → Side Guide mechanism → Feeding-to-length → Fly Shearing Machine → Belt Conveying Device → Products Stacking

|

No |

Part |

Specification |

|

1 |

Raw Material |

Aluminum,Metal,Steel,Copper and so on |

|

2 |

Coil Thickness |

0.3-3MM |

|

3 |

Coil Width |

1500MM |

|

4 |

CoilOuterDiameter |

≤Φ1800mm |

|

5 |

CoilInnerDiameter |

Φ508mm、Φ610mm(With rubber sleeve) |

|

6 |

Coil Weight |

20T |

|

7 |

Cutting Length |

500-600MM |

|

8 |

Shearing Speed |

0~80m/min |

|

9 |

Strip through speed |

0~15m/min |

|

10 |

Power |

380V/50Hz/3Phase |

1. High degree of automation: the whole production line adopts advanced control system to realize highly automated production process, which reduces manual operation and improves production efficiency and safety.

2. Increased production efficiency: Due to the increased automation, the working speed and continuous production capacity of the production line have been significantly improved, which is able to quickly handle a large number of orders, and the production speed can reach 80M/Min.

3. High accuracy: Utilizing precise measuring and control equipment, the line ensures the dimensional accuracy of the sheared sheets, meeting high manufacturing standards.

4. Excellent sheet quality: the leveler and shear mechanism in the production line can ensure that the sheet is flat and free of scars, improving the quality of the finished product, and the design of the 6-weight roll leveler improves the quality of coil leveling.

▷ Precision Manufacturing: Advanced manufacturing techniques and equipment are used to ensure the accuracy and consistency of each component.

▷ Rigorous Testing: Rigorous testing is conducted before the equipment leaves the factory, including performance testing, durability testing and safety testing.

▷ Quality Control System: A comprehensive quality control system is implemented to monitor the entire production process to ensure that every step meets quality standards.

KINGREAL STEEL SLITTER will offer modern centralized control and monitoring systems, as well as cut-to-length lines for use with a variety of stacking lines and shears, all of which contribute to increased productivity and product quality.

KINGREAL STEEL SLITTER has our own factory, including processing workshop, cnc machining workshop, assembly workshop and the final production workshop, which located in the Foshan,near Guangzhou.

(KINGREAL welcome all customer to visit our factory)

KINGREAL STEEL SLITTER has a specialized after-sales team that can provide customers with after-sales installation and commissioning services. And will guide the customer's factory workers to start the operation to ensure that the equipment can run normally.