Metal cut to length lines not only improve production efficiency but also ensure product quality. With continuous technological advancements, KINGREAL SLITTING has further refined its metal cut to length machine solutions in 2025. This article will explain how KINGREAL SLITTING provides complete metal cut to length line manufacturing solutions to meet diverse customer needs.

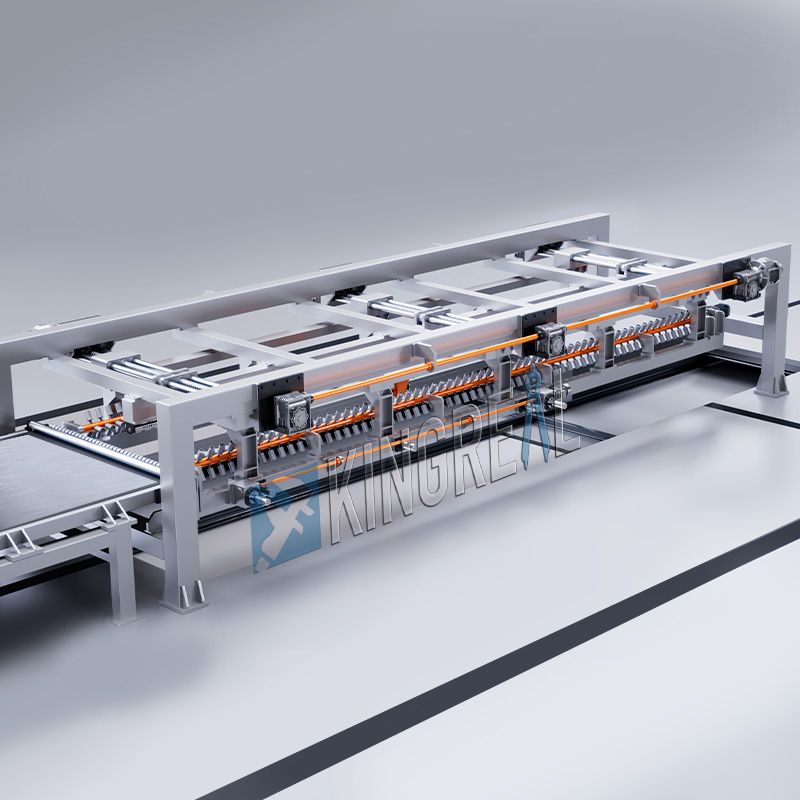

Metal cut to length lines are automated production equipment used to uncoil, level, cut, and stack metal sheets into desired lengths. They are widely used for processing cold-rolled and hot-rolled carbon steel, silicon steel, tinplate, stainless steel, and various other types of coated metal coils. Metal cut to length machines primarily consist of precision components such as a loading trolley, decoiler, leveler, feeder, shear conveyor, and stacker.

|

Model |

Material Thickness(mm) |

Material Width(mm) |

Cutting Accuracy(mm) |

Leveling Accuracy (mm/m²) |

Cutting Speed(m/min) |

Uncoil Weight(Tons) |

Remarks |

|

Model 1 |

0.15-0.5 |

500-1300 |

±0.3 |

1-2 |

30-60 |

6/15 |

Cutting speed is based on a 2000mm vibration length. Technical parameters and equipment configuration are determined according to customer requirements |

|

Model 2 |

0.35-1.5 |

500-1300 |

±0.3 |

1-2 |

30-60 |

6/15 |

|

|

Model 3 |

0.35-2 |

150-650 |

±0.3 |

1-2 |

30-60 |

5 | |

|

Model 4 |

0.35-2 |

500-1300 |

±0.3 |

1-2 |

30-60 |

6/15 |

|

|

Model 5 |

0.35-2 |

500-1600 |

±0.3 |

1-2 |

30-20 |

15 | |

|

Model 6 |

0.50-2 |

900-1850 |

±0.5 |

1-2 |

25-50 |

20 | |

|

Model 7 |

0.50-3 |

900-2000 |

±0.5 |

1-2 |

25-50 |

15 | |

|

Model 8 |

0.50-3 |

900-2000 |

±0.5 |

1-2 |

25-50 |

20 | |

|

Model 9 |

1-6 |

900-2000 |

±1 |

2-3 |

10-30 |

20 | |

|

Model 10 |

2-8 |

900-2000 |

±1 |

2-3 |

10-25 |

20 | |

|

Model 11 |

3-12 |

900-2000 |

±1.5 |

2-4 |

10-25 |

20 | |

|

Model 12 |

4-16 |

900-2000 |

±2 |

2-4 |

6-20 |

30 | |

|

Model 13 |

6-20 |

900-2000 |

±2 |

2-4 |

6-16 |

30 |

As a leading manufacturer in the industry, KINGREAL SLITTING is committed to providing customers with complete metal cut to length machine solutions to meet the processing needs of various metal materials. Regardless of the metal material, thickness, shear length, production speed, or coil weight required, KINGREAL SLITTING can provide customized metal cut to length line and solutions.

3.1 Classification by Material Thickness

Light Gauge Cut to Length Line: Designed for processing metal coils with a thickness of 0.2-3mm, it is suitable for applications with high surface finish requirements, such as automotive parts and coated strip.

Medium Gauge Cut to Length Line: Suitable for coils with a thickness range of 0.3-6mm, it fills the gap between light gauge cut to length lines and heavy gauge cut to length lines, meeting a wider range of processing needs.

Heavy Gauge Cut to Length Line: Designed for processing metal coils with a thickness of 6-20mm, it is suitable for heavy industrial applications and can handle even thicker materials.

3.2 Classification by Shearing Method

Fly Shearing Cut to Length Lines: Capable of transverse shearing of moving rolled products without stopping the metal cut to length machine, with a maximum speed of 80 m/min, suitable for high-efficiency production environments.

Fixed Shearing Cut to Length Lines: Require metal cut to length line stoppage during shearing and have a relatively slow speed of approximately 50 m/min. They are suitable for small-scale production or customers with low efficiency requirements.

Swing Shearing Cut to Length Lines: Based on customer-specified sheet metal shapes, the shears automatically swing at a set angle to cut. They can cut a variety of sheet metal shapes, such as trapezoids and parallelograms, with speeds of up to 80 m/min.

Rotary Shearing Cut to Length Lines: Utilizing high-speed rotary shearing technology, they eliminate any markings caused by shearing stops. They are suitable for fine processing and have a maximum speed of 80 m/min.

3.3 Meeting Special Needs

KINGREAL SLITTING also offers metal cut to length machine solutions tailored to specific needs:

Metal Cut to Length Line with Dual Levelers: To meet customers' stringent requirements for sheet metal surface flatness, the metal cut to length machine is equipped with two levelers, meaning the sheet metal undergoes two leveling processes before shearing, effectively ensuring sheet metal flatness.

Metal Cut to Length Line with Dual Stackers: Increases production speed, with automatic stacking ensuring both quality and speed.

Metal Cut to Length Line with Laminating Device: Coats the sheet metal with a layer of film during the shearing process to prevent blade scratches and ensure a scratch-free surface.

3.4 Accessories and Different Performance Parameters

To meet diverse customer needs, KINGREAL SLITTING metal cut to length machines can be equipped with components with varying performance parameters:

Levelers for metal cut to length machine: Depending on processing requirements, customers can choose between six-stage, four-stage, or two-stage leveling machines, with both primary and final leveling machines for leveling.

Shear feed system for metal cut to length machine: Fixed-length shear feed can utilize conventional mechanical and electrical coordination, digital frequency conversion technology, or AC servo technology to ensure precise and efficient cutting.

Cut to length machine for metal cut to length line: Choose between conventional mechanical or hydraulic models to suit different shearing tasks.

As a highly efficient production tool, metal cut to length lines offer several distinct advantages:

-Efficient metal cut to length line: Automated production processes significantly improve production efficiency and reduce the need for manual intervention.

-High-precision metal cut to length machine: Advanced control technology ensures precise cutting lengths, reduces material waste, and improves product quality.

-Flexible metal cut to length machine: Shearing lengths and speeds can be quickly adjusted based on customer needs and market fluctuations.

-Intelligent metal cut to length line: Data collection and analysis enable real-time monitoring and optimization of the production process, improving production management.

Metal cut to length lines are widely used in various industries, including but not limited to:

Metal cut to length machine in metalworking: Used for cutting metals such as steel and aluminum, particularly in the construction and automotive industries.

Metal cut to length line in construction: Provides custom-length construction materials such as rebar and precast concrete. Plastic Manufacturing: Used for cutting various plastic films and sheets to meet diverse market demands.

Metal cut to length machine in automotive industry: Provides precise shearing services for automotive parts manufacturing, meeting high quality standards.