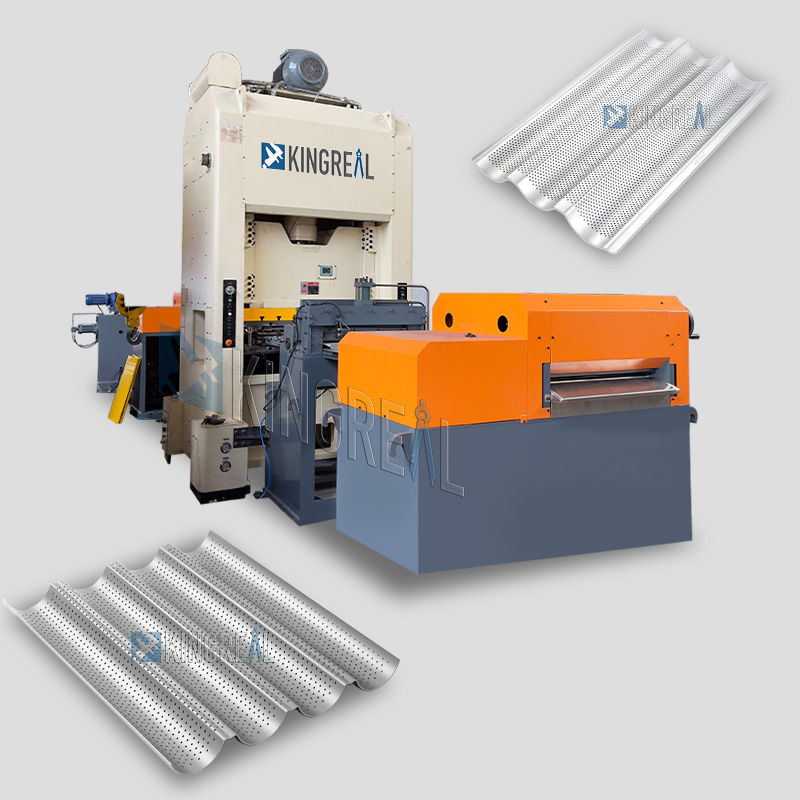

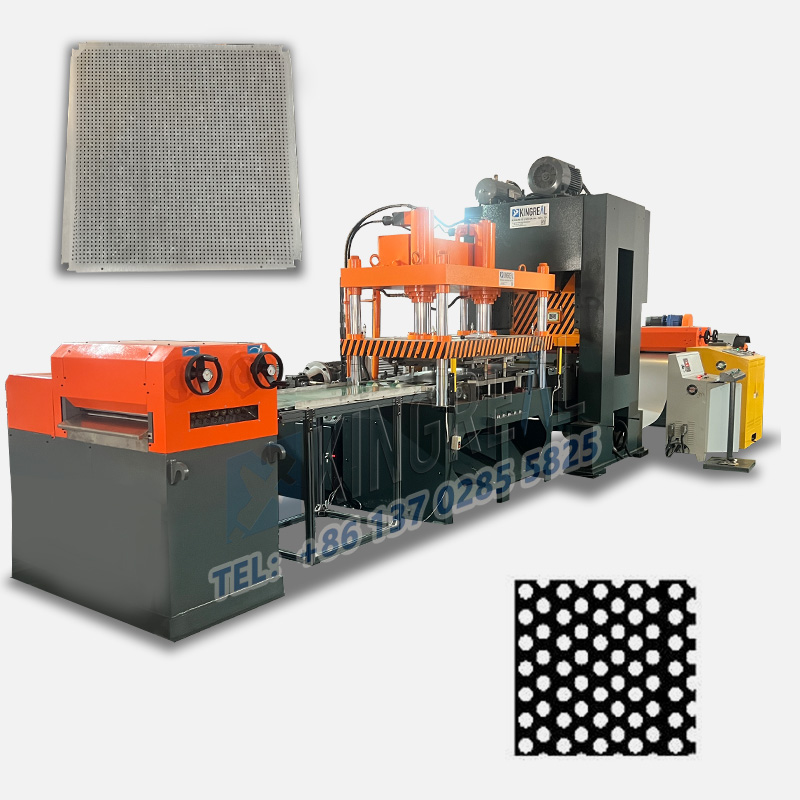

This KINGREAL STEEL SLITTER Metal Baguette Tray Perforated Punching Making Machine is specifically designed for producing baguette trays. And the metal perforated making machine can punch a wide variety of hole shapes and diameters in metal materials of varying thicknesses to meet individual customer needs.

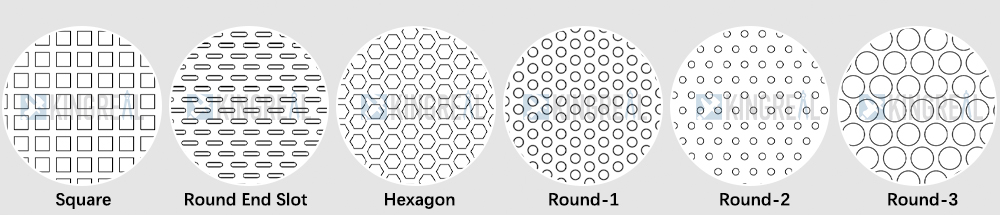

KINGREAL STEEL SLITTER Metal Perforated Making Machine is a metalworking process that involves creating a series of holes in sheet metal. This process is usually done using a punch press mold, which can be used to create holes of different sizes and shapes as needed. Perforated wire is used in a wide range of applications, such as in air filters, exhaust mufflers, thermal insulation panels, partitions, and many other applications.

The advantage of metal perforated making machine is that it offers a wide choice of materials, materials, shapes, plate sizes, plate thicknesses, hole diameters, etc., to suit different applications. In addition, metal perforated making machine can be used for decorative purposes, such as the use of perforated metal plates as wall materials, partitions, lighting fixtures, etc., both inside and outside buildings.

Recently KINGREAL STEEL SLITTER has also provided a solution for the production of metal perforated making machine for customers selling metal baguette trays, which are designed and produced according to the material of the metal baking trays, the need for punching and the characteristics of the product.

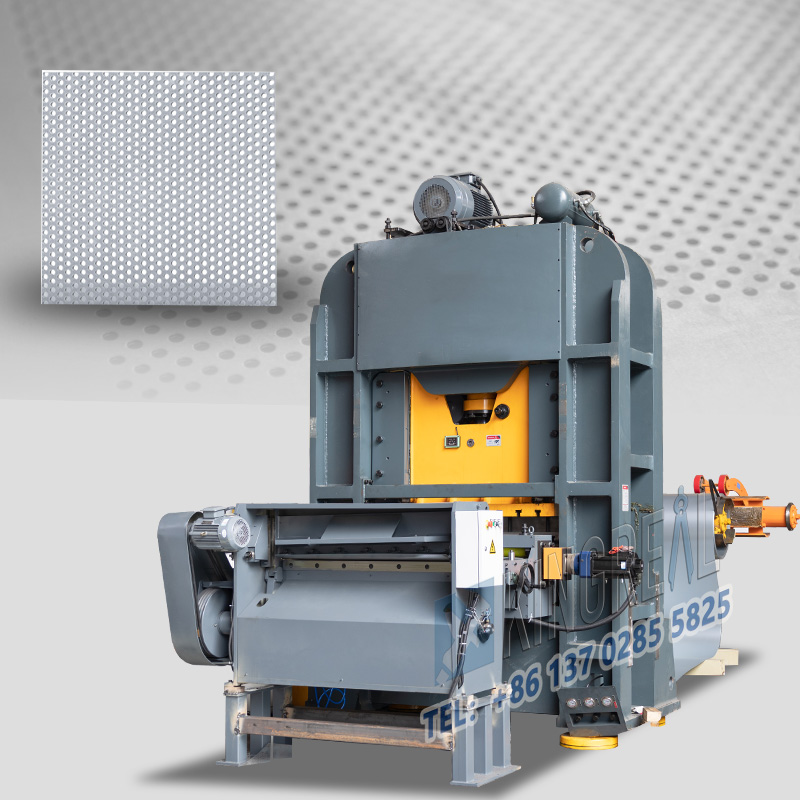

The working principle of the metal perforated making machine is to use the punching machine to install the raw material on the working machine platform, and the punching die acts on the material under the drive of the power mechanism (e.g., manually-driven or hydraulically-driven) to complete the punching operation.

The metal perforated making machine can perform operations such as sheet processing, stamping, molding, embossing, etc., forcing the metal into the die to create the desired holes. This technique is widely used to manufacture sheet metal with various hole patterns, such as covers for machinery and equipment, air filters, exhaust mufflers, etc. The perforated punching machine is also used to make metal sheets with a variety of hole shapes.

The precision and speed of the metal perforated making machine can be adjusted by different types of metal perforated making machines to suit different production needs.

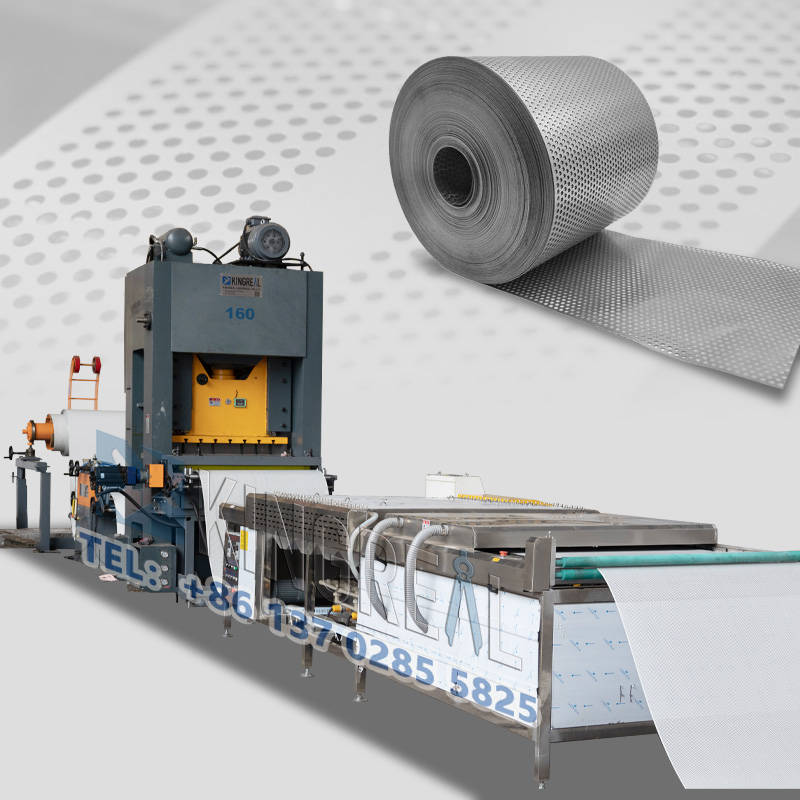

Hydraulic Decoiler -- Pre-Straightener -- 125 Ton Gantry Punching Press -- Servo Feeder Device -- Cut To Length Machine/Recoiler Machine(for your choice)

|

Raw Materials Thickness |

0.4-0.6 mm |

|

Max Production Size |

1250mm width |

|

Holes Size |

Φ3 mm |

|

Production Speed |

100-160 SPM |

|

Uncoliler motor Power |

3 KW |

|

Feeder motor power |

7.5 KW |

|

Gantry press power |

18.5 KW |

Decoiler Part for Metal Perforated Making Machine:

Decoiler for Metal Perforated Making Machine is a specialized equipment used in metal perforated making machine, which is mainly used to carry and unroll steel coils for further processing.

Structural features: the uncoiler usually has a box-shaped welded structure, and the frequency-controlled motor drives the reel shaft to provide the main power after deceleration through a gear box. The reel is a hollow shaft supported on the gear box body by two bearings, with transmission spur gears mounted between the bearings. Functional features: The unwinder is capable of unwinding the strip while maintaining the strip tension, and it is also capable of automatic strip centering under center control.

Metal Punching Machine for Metal Perforated Making Machine

▶ High Speed Precision: This press is capable of operating at high speeds while maintaining the accuracy of the stamping process.

▶ Stable structure: The gantry structure design provides a stable working platform for large-scale and heavy-duty stamping operations.

▶ Automatic Lubrication System: Equipped with an automatic lubrication system to ensure the stability of the machine during prolonged operation and prolong the service life of the metal perforated making machine.

▶ Frequency conversion speed control: the speed of the press is controlled by frequency converter, which can adjust the stamping speed according to different processing requirements.

▶ Air friction clutch and brake: Adopting air friction clutch and brake system improves the response speed and safety of the machine.

▶ Fixed-point stop function: able to stop precisely at the top dead center during the stamping process, which is convenient for mold replacement and maintenance.

Servo Motor Feeding Device for Metal Perforated Making Machine

▶ Servo motor feeding device in metal perforated making machine is a high precision automation equipment, which utilizes the precise control of servo motors to achieve accurate feeding of materials.

▶ Precise control: The servo motor can precisely control the feeding speed and position to ensure that the material is conveyed according to the set parameters.

▶ High Efficiency: The fast response time of the servo motors increases the efficiency of the metal perforated making machine and reduces downtime.

▶ Easy to program: Servomotor feeders are usually equipped with a user-friendly interface, making it easy for operators to program them for different production needs.

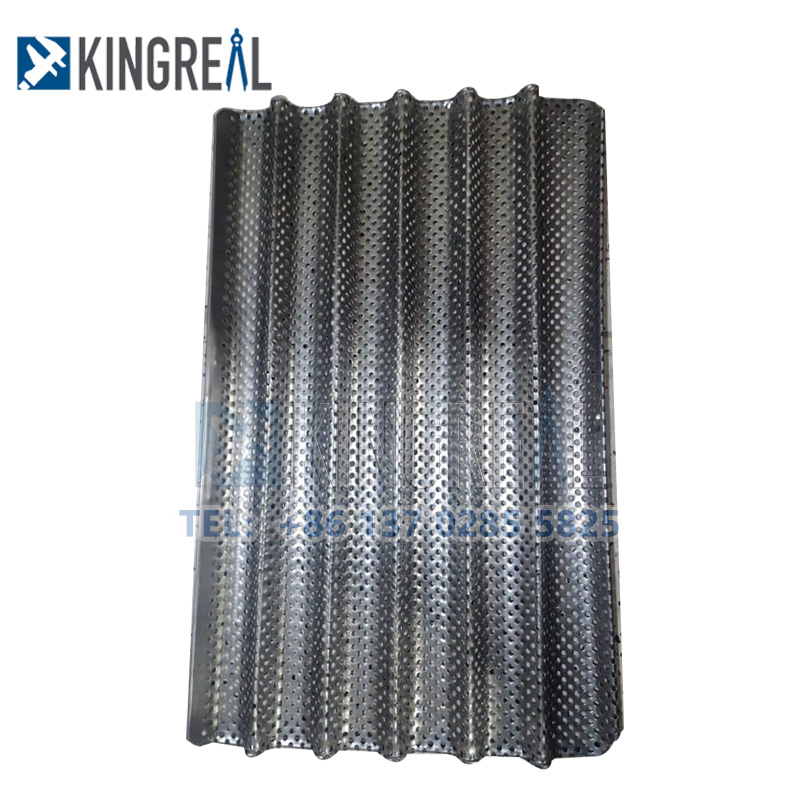

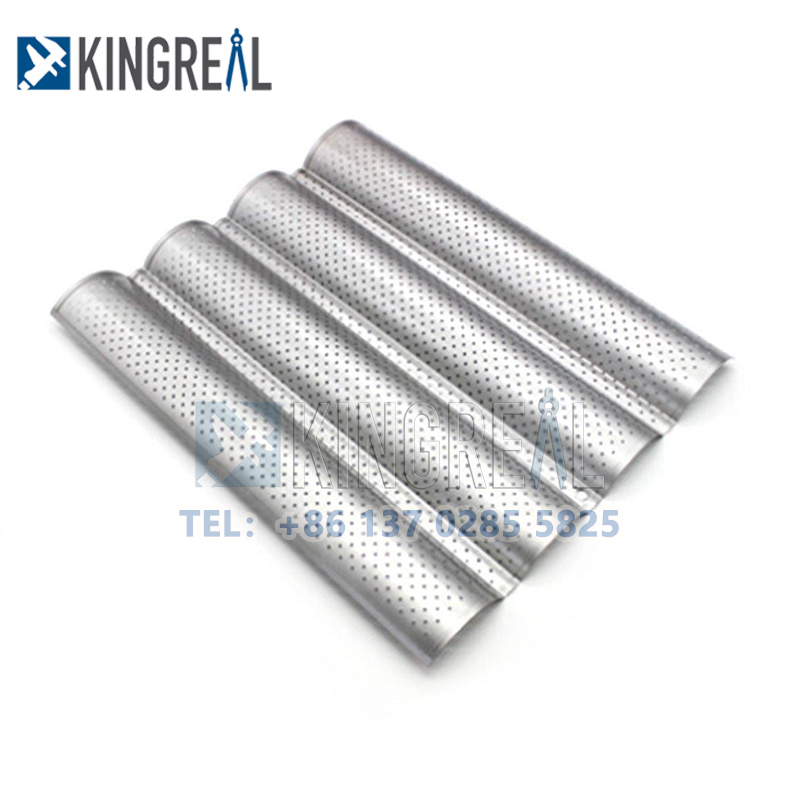

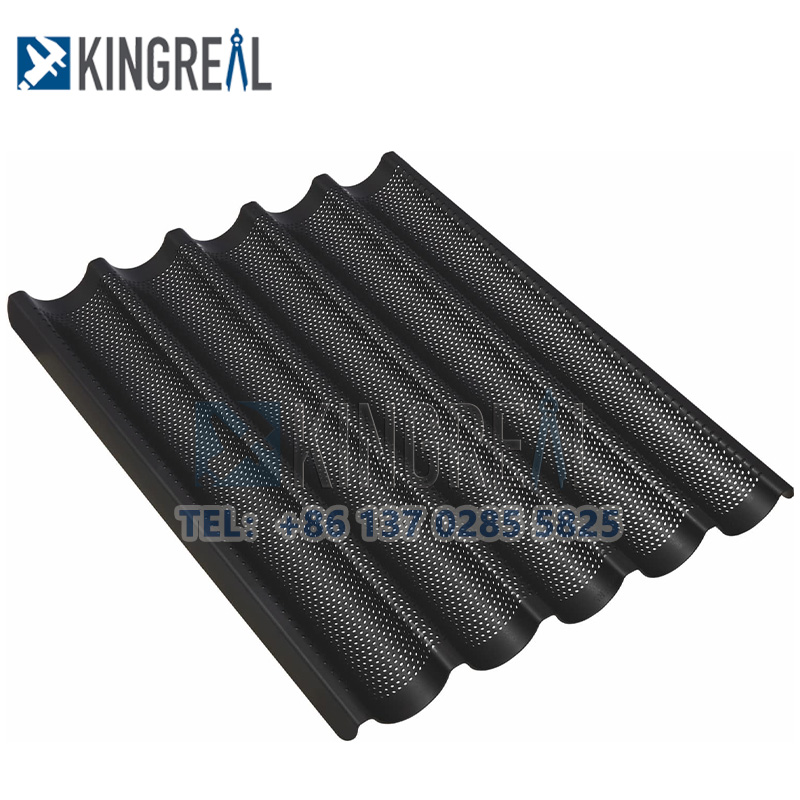

A perforated metal baguette baking pan is a baking tool that is usually made of metal and designed with a series of holes in the surface. These holes help to distribute heat more evenly for better ventilation and heat transfer.

|

|

|

|

|

|

|

|

|