KINGREAL STEEL SLITTER high speed slitting line can meet customers' production requirements to ensure product dimensional accuracy, surface quality, production efficiency and other production requirements, and is suitable for high-level requirements. And the high speed slitting machine has the characteristics of advanced technology, reliable equipment, perfect technology, mature manufacturing and easy maintenance.

|

The high speed slitting line offered by KINGREAL STEEL SLITTER is specially designed to meet various metal coil processing needs. From aluminum to stainless steel, from hot-rolled strips to the thinnest cold-rolled strips, with strip widths from 120 to 2,500 mm and strip thicknesses from 0.2 to 16.0 mm, KINGREAL STEEL SLITTER can provide customized high speed slitting machine manufacturing solutions in various sizes. KINGREAL STEEL SLITTER high speed slitting line adopts a user-friendly design concept to ensure simple operation and stable performance, making it suitable for production environments of all sizes. Each parameter and performance of the high speed slitting machine are customized according to the customer's specific project requirements. Through strict processing time control and high production speed, KINGREAL STEEL SLITTER high speed slitting line can achieve mass production, helping companies reduce production costs and improve competitiveness. Moreover, KINGREAL STEEL SLITTER high speed slitting machines have a high level of automation and the cutting speed can reach 200m/min (or even 230m/min), which greatly improves production efficiency. In the design of the high speed slitting machine, KINGREAL STEEL SLITTER high speed slitting line not only pays attention to the stability of performance, but also takes into account the user's operating experience. Equipped with an intuitive control system and advanced tension control technology, the high speed slitting line ensures stable performance and high-quality cutting results. The user-friendly interface simplifies operation and maintenance, making it ideal for high-volume production environments. |

|

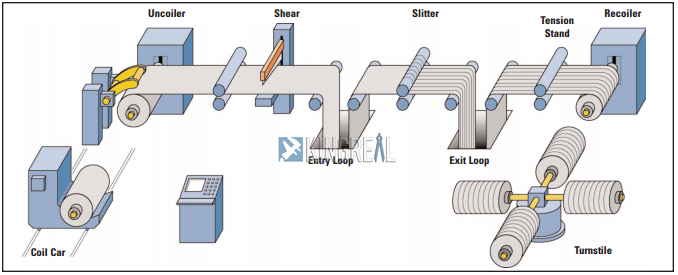

Loading trolley/Coil car→ decoiler→ guiding device→ entry crop shear → centering device→ rotary slitter→ scrap winder→ buffer pit→ pre-separating and tensioning→ recoiler→ unloading trolley/coil car

|

Model |

Raw material width (mm) |

Thickness range (mm) |

Finished product width (mm) |

Cutting speed (m/min) |

|

Model 1 |

400-1300 |

0.8-4.5 |

60-1250 |

0-200 |

|

Model 2 |

600-1600 |

1.0-6.0 |

60-1550 |

0-200 |

(If you need more parameter information of high speed slitting machine models, please contact KINGREAL STEEL SLITTER, we will provide professional consultation and support.)

|

·Highly automatic: effectively reduce non-production time and improve production efficiency. ·High-quality final product: High-quality products are ensured by strictly controlling the cutting process. ·High production capacity: Reduce tooling time while maintaining high production speed to achieve optimal equipment turnover rate. ·High precision and accuracy: Using high-precision cutter shaft bearings to achieve high-precision cutting to meet the needs of different users. ·Burr-free cutting: The deflection of the knife axis is extremely small, ensuring edge quality when cutting a large number of cuts. ·Improved coiling accuracy: As the diameter of the coil increases, the coiling accuracy increases. ·Adaptable to a variety of materials: Use gentle surface treatment technology for sensitive materials to protect material quality. |

|

The high speed slitting machine is equipped with a precision slitting head with high accuracy to achieve minimal burrs and excellent edge quality. The automatic tool positioning system enables quick tool changes, improving efficiency and production flexibility. The highly sensitive tension control unit ensures stable material winding, especially suitable for delicate or thin gauge materials. KINGREAL STEEL SLITTER high speed slitting lines support a wide range of materials, including stainless steel, aluminum and copper, providing customers with a wide range of processing options. In addition, the advanced PLC control system provides a friendly operation interface to achieve real-time monitoring and fault detection. In terms of high speed slitting machine design, the compact structure not only saves factory space, but also does not affect the performance of the high speed slitting line. The high speed slitting machine's surface finish and stable output make it the best choice for industries that have high requirements for processing accuracy and surface quality. The user-friendly design of the operating system allows for easy setup and quick adjustments, significantly reducing training time and the chance of operator error. And advanced tension control ensures smooth, scratch-free processing of fine materials. These features significantly increase overall efficiency, minimizing maintenance requirements and downtime.

|

|

|

High speed slitting machines are widely used in industries that require precise and efficient coil processing, including stainless steel service centers, kitchenware and appliance manufacturing, automotive parts, building materials, and HVAC systems. The high speed slitting line is ideal for cutting stainless steel coils into narrow strips for further processing such as stamping, forming or welding. Moreover, the high speed slitting machine can handle rolls of various sizes and thicknesses, allowing it to meet different production needs. The high speed slitting line produces sheet metal with high cutting precision and a smooth edge finish ensuring excellent results.

Type of material to be processed: Each material has different characteristics when processed, such as hardness, brittleness, etc.

Material thickness and strength: This will directly affect the selection of high speed slitting machines and the setting of process parameters.

Production volume and precision requirements: High-demand high speed slitting machines need to be designed more precisely to ensure the stability and consistency of output.

KINGREAL STEEL SLITTER has successful high speed slitting line sales cases in many countries around the world (including Brazil, Saudi Arabia, Italy, Mexico, Indonesia, Canada, etc.). Every high speed slitting machine sold is fully customized to the individual customer's needs, unique and suitable for any production environment. Whether it is a mini metal coil slitting machine, a high speed slitting machine equipped with a steel packaging line, or a double slitter head coil slitting machine, KINGREAL STEEL SLITTER has rich design, R&D and production experience. KINGREAL STEEL SLITTER has comprehensive after-sales service and continuous high speed slitting line status tracking capabilities to ensure that customers have no worries during the entire use process.

Don't hesitate, contact KINGREAL STEEL SLITTER now to get the latest quotation of high speed slitting lines and personalized high speed slitting machine manufacturing solutions!