KINGREAL STEEL SLITTER 850MM Cut To Length Line Machine is designed to process rolls up to 850MM in width and is capable of uncoiling, leveling, shearing and stacking. Please contact us for more information.

KINGREAL STEEL SLITTER 850MM Cut To Length Line is one of the hottest products in recent times, professionally designed to handle 850MM wide rolls of different materials. Compared to the common web widths of 1300MM, 1600MM and 2000MM, the 850MM width is a smaller web, which requires more precision in cutting and leveling, making the 850MM cut to length machine more specialized.

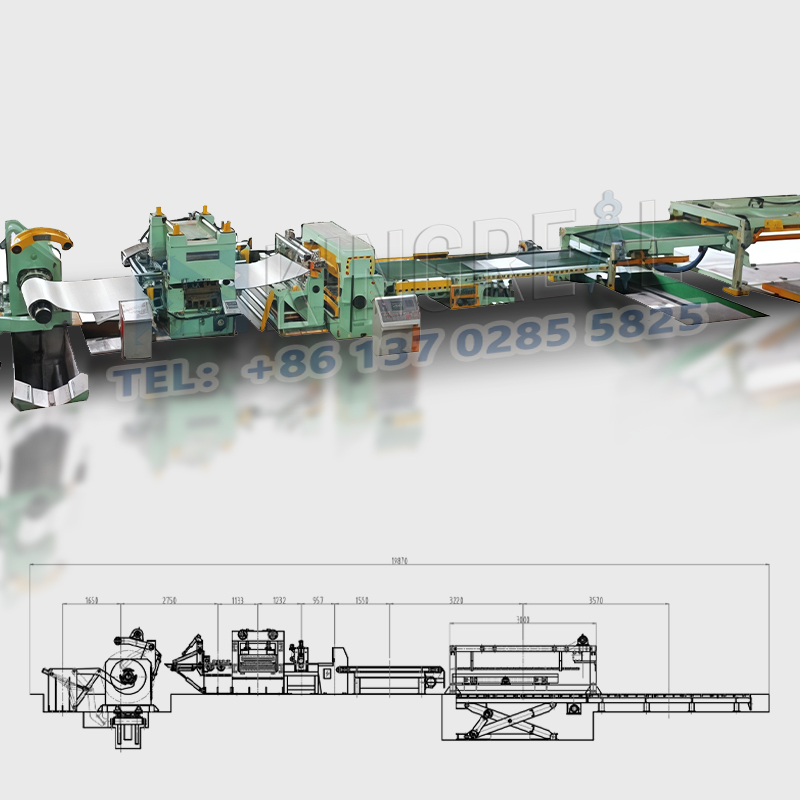

The KINGREAL STEEL SLITTER 850MM Cut To Length Line is capable of handling coil widths ranging from 850MM to 2000MM, which requires a much higher level of design for the production line's individual equipment. The 850MM Cut To Length Machine consists of the following components: uncoiling, leveling, feeding, shearing, trimming, and stacking components, and is capable of accurately cutting coils into sheets for further applications.

KINGREAL STEEL SLITTER has been in the field of coil processing equipment for more than 20 years, and is constantly committed to improving its professionalism and after-sales service capabilities. KINGREAL STEEL SLITTER is able to design 850MM cut to length line solutions according to the customer's needs and help them to realize the best production efficiency. At present, 850MM Cut To Length Line has been successfully sold to Russia, Turkey, Saudi Arabia, Chile and other countries and regions.

Hydraulic Decoiler → Pinch Rollers to enter the Leveling Machine → Short Looper Station → Side Guide mechanism → Feeding-to-length → Fly Shearing Machine → Belt Conveying Device → Products Stacking → Discharging Trolley

|

No. |

Name |

Qty |

|

1 |

Raw Material Table |

1 Unit |

|

2 |

Trolley for Feeding |

1 Unit |

|

3 |

Front Auxiliary Support |

1 Unit |

|

4 |

Uncoiler + Unwinding Device |

1 Set |

|

5 |

Straightener |

1 Unit |

|

6 |

Short Looper |

1 Unit |

|

7 |

Sides Guiding Device |

1 Unit |

|

8 |

Pinch NC Length Measurer |

1 Unit |

|

9 |

Fly Shearing Machine |

1 Unit |

|

10 |

Conveying Machine |

1 Unit |

|

11 |

Product Stacking Machine |

1 Unit0 |

|

Raw Material |

Galvanized Iron Sheet, Galvanized Aluminum Sheet |

|

Coil Thickness |

0.3-3MM |

|

CoilWidth |

≤1600mm |

|

Coil weight |

≤ 20T |

|

Shearing Speed |

0-80M/Min |

|

Strip through speed |

0~15m/min |

|

Power |

380V/50Hz/3Phase |

|

Control |

AC frequency conversion control |

Hydraulic Decoiler is an important part of a 850MM cut to length line, mainly used to unroll and guide metal coils to shearing or other processing equipment.

● Supporting Coil: Supports the coil by tightening the bore of the coil to ensure its stability.

● Strip Unwinding: Unwinds the strip smoothly while maintaining strip tension.

● Hydraulics: The hydraulic system of the Uncoiler is used to drive mechanical components, such as the support arm unit, to enhance the stability of the coil.

High Quality Shearing Machine for 850MM Cut to Length Line

● Function: It is used for cutting of fixed-length materials.

● Main structure: main frame, blade, pneumatic clutch, electric part, etc.

● Main frame: The whole frame is welded with high-quality carbon structural steel and has been annealed after welding.

● Blade: The blade is made of Cr12 material, the heat treatment hardness reaches HRC62 degrees, and the four-sided cutting edge can be replaced.

Auto Stacker for 850MM Cut to Length Line

Stacking devices are designed to increase metal processing efficiency, reduce manual handling and ensure that processed sheets are neatly stacked for subsequent transportation or further processing. These devices are very important in the metal processing industry, especially in 850MM cut to length lines where large quantities of sheet metal need to be handled.

KINGREAL STEEL SLITTER places great emphasis on 850mm cut to length machine quality and is committed to providing comprehensive services to its customers, including providing personalized 850mm cut to length machine manufacturing solutions, accompanying customers on 850mm cut to length machine tours, and inviting them to test drives. As a result, the 850mm cut to length machines KINGREAL STEEL SLITTER sells are perfectly matched to customers' actual production needs, operating smoothly and generating significant profits for them.

1.What is a Coil Cut To Length Machine for Automotive?

2.What is light gauge cut to length line?

3.What is the use of heavy gauge cut to length machine?

4.What is the principle of metal cut to length machine?

5.What are the core devices of stainless steel cut to length machine?